Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

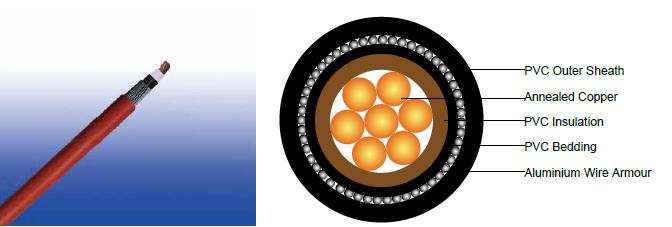

600/1000V PVC Insulated, PVC Sheathed, Armoured Power Cables to IEC 60502 (Single Core)

Application

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings.

Standards

Basic design to to IEC 60502-1

Fire Performance

Flame Retardance (Single Vertical Wire Test) | IEC 60332-1 |

Voltage Rating

600/1000V

Cable Construction

Conductor | Annealed copper wire, stranded according to BS EN 60228 class 2. |

Insulation | PVC/A according to IEC 60502-1. |

Inner Covering | Extruded PVC or polymeric compound. |

Armouring | Aluminium wire |

Outer Sheath | Extruded PVC Type ST1/ST2 according to IEC 60502-1. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Brown or blue, Other colours can be offered upon request. |

Sheath Colour | Black, other colours can be offered upon request. |

Physical AND THERMAL PROPERTIES

Maximum temperature range during operation (PVC) | 70°C | ||||||

Maximum short circuit temperature (5 Seconds) | 160°C(≤300 mm²); 140°C(>300 mm²) | ||||||

| |||||||

Minimum bending radius |

| ||||||

| |||||||

Construction Parameters

Conductor | FGD300 1VVMAV-R | ||||||

|---|---|---|---|---|---|---|---|

No. of Cores xCross Section | Class of Conductor | Nominal Insulation Thickness | Nominal Inner | Nominal Armour Wire | Nominal Sheath Thickness | Approx. Overall | Approx. Weight |

No.xmm2 |

| mm | mm | mm | mm | mm | kg/km |

2 | 1.0 | 1.0 | 0.8 | 1.8 | 11.5 | 213 | |

2 | 1.0 | 1.0 | 0.8 | 1.8 | 12.0 | 247 | |

2 | 1.0 | 1.0 | 0.8 | 1.8 | 12.8 | 310 | |

2 | 1.0 | 1.0 | 0.8 | 1.8 | 13.7 | 394 | |

2 | 1.2 | 1.0 | 0.8 | 1.8 | 15.2 | 534 | |

2 | 1.2 | 1.0 | 1.25 | 1.8 | 17.2 | 713 | |

2 | 1.4 | 1.0 | 1.25 | 1.8 | 18.9 | 893 | |

2 | 1.4 | 1.0 | 1.25 | 1.8 | 20.3 | 1158 | |

2 | 1.6 | 1.0 | 1.6 | 1.8 | 23.0 | 1558 | |

2 | 1.6 | 1.0 | 1.6 | 1.8 | 24.4 | 1863 | |

2 | 1.8 | 1.0 | 1.6 | 1.8 | 26.2 | 2214 | |

2 | 2.0 | 1.0 | 1.6 | 1.9 | 28.2 | 2697 | |

2 | 2.2 | 1.0 | 1.6 | 1.9 | 31.0 | 3402 | |

2 | 2.4 | 1.0 | 2.0 | 2.1 | 34.4 | 4282 | |

2 | 2.6 | 1.2 | 2.0 | 2.2 | 38.6 | 5360 | |

2 | 2.8 | 1.2 | 2.0 | 2.3 | 41.8 | 6583 | |

2 | 2.8 | 1.2 | 2.5 | 2.4 | 46.2 | 8401 | |

2 | 2.8 | 1.4 | 2.5 | 2.6 | 50.5 | 10515 | |

2 | 3.0 | 1.4 | 2.5 | 2.7 | 55.0 | 12968 | |

Introduction

In the realm of electrical engineering, the selection of appropriate power cables is critical to ensuring safety, reliability, and efficiency in various applications. Among the diverse range of cables available, 600/1000V PVC insulated, PVC sheathed, armoured power cables (single core) designed to IEC 60502-1 standards are widely used in demanding environments. These cables are engineered for durability, fire resistance, and optimal electrical performance, making them suitable for critical infrastructure in South Africa, including power stations, mass transit systems, and high-rise buildings.

Fire Performance

Fire safety is a paramount concern in cable selection, particularly in densely populated or critical infrastructure settings. These cables comply with IEC 60332-1 for flame retardance, ensuring they resist flame propagation in single vertical wire tests. Additional fire performance standards, such as IEC 60332-3, UL 1581, and UL 1666, can be met depending on the oxygen index of the PVC compound and overall cable design. For enhanced safety, low-smoke PVC (LSPVC) options are available, reducing toxic emissions in fire scenarios.

Applications in South Africa

The versatility of 600/1000V PVC insulated, PVC sheathed, armoured power cables makes them indispensable in several high-demand sectors in South Africa:

Power Stations: These cables are used for reliable power distribution within power generation facilities, such as Eskom’s coal-fired power plants. Their armouring protects against mechanical damage in harsh industrial environments.

Mass Transit Systems: The Gautrain, South Africa’s high-speed rail network, relies on these cables for power supply to signalling and control systems, where fire safety and reliability are critical.

Petrochemical Plants: In facilities like Sasol’s Secunda plant, the cables’ optional hydrocarbon and oil resistance make them ideal for environments exposed to chemicals.

High-Rise Buildings: In urban centres like Johannesburg and Cape Town, these cables are used in high-rise buildings for power distribution, with LSPVC options ensuring compliance with stringent fire safety regulations.

Hospitals and Airports: Facilities such as the Chris Hani Baragwanath Hospital and OR Tambo International Airport utilise these cables for critical power systems, where uninterrupted supply and fire resistance are paramount.

Advantages and Limitations

Advantages

Durability: The aluminium wire armouring and robust PVC sheath provide excellent mechanical and environmental protection.

Fire Safety: Compliance with IEC 60332-1 and optional LSPVC enhance safety in fire-prone environments.

Versatility: Customisable options (e.g., UV resistance, anti-rodent properties) cater to diverse applications.

Cost-Effectiveness: PVC insulation and sheathing offer a cost-effective solution compared to alternatives like XLPE.

Limitations

Temperature Constraints: The 70°C operating limit may be restrictive in high-temperature environments, where XLPE cables (rated up to 90°C) may be preferred.

Weight: Larger conductor sizes (e.g., 1000 mm²) result in significant weight (up to 12,968 kg/km), posing challenges for installation.

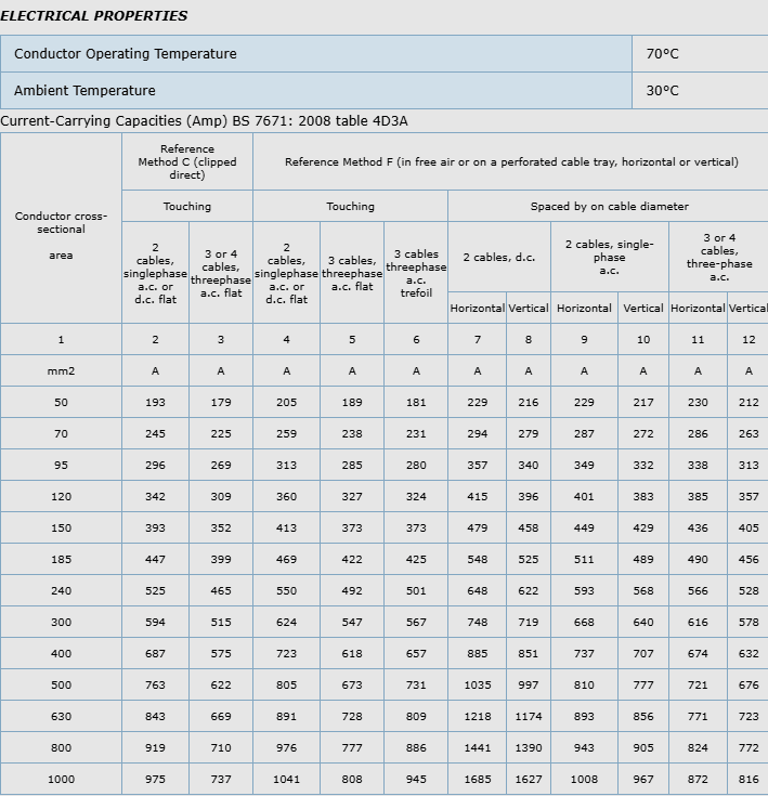

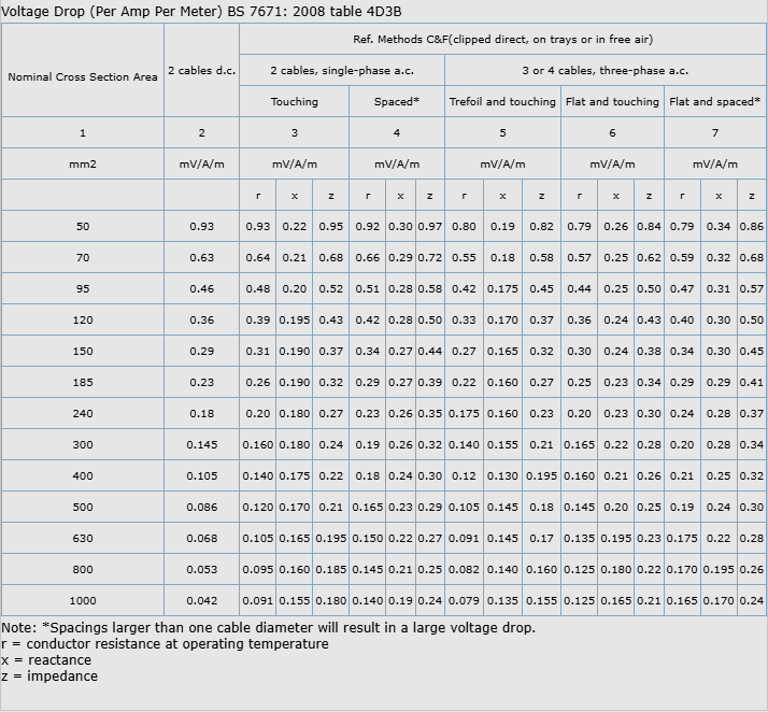

Voltage Drop: In spaced configurations, voltage drop can be significant, requiring careful design to ensure efficiency.

The 600/1000V PVC insulated, PVC sheathed, armoured power cables to IEC 60502-1 are a cornerstone of South Africa’s electrical infrastructure, offering a balance of durability, safety, and performance. Their robust construction, compliance with international standards, and adaptability to harsh environments make them ideal for applications ranging from power stations to high-rise buildings. Recent case studies, such as Medupi Power Station and Cape Town International Airport, underscore their reliability in real-world scenarios. While limitations like temperature constraints and weight exist, ongoing advancements in cable technology promise to enhance their utility. As South Africa continues to develop its infrastructure, these cables will remain a vital component in ensuring safe and efficient power distribution.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430