Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V PVC Insulated, PVC Sheathed, Unarmoured Power Cables to IEC 60502 (Single Core)

Application

IEC 60502-1 600/1000V PVC Insulated, PVC Sheathed Unarmoured Power Cables are mainly use in fixed installations in industrial areas, buildings and similar applications but not for burial in the ground, either directly or in ducts.

Standards

Basic design to to IEC 60502-1

Fire Performance

Flame Retardance (Single Vertical Wire Test) | IEC 60332-1-2 |

Voltage Rating

600/1000V

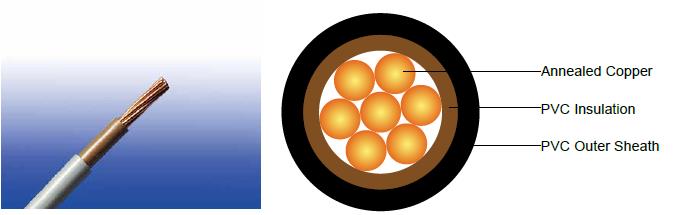

Cable Construction

Conductor | Plain annealed copper, stranded according to IEC 60228 class 2. |

Insulation | PVC/A according to IEC 60502-1. |

Outer Sheath | Extruded PVC Type ST1/ST2 according to IEC 60502-1. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Brown or blue, other colours can be offered upon request. |

Sheath Colour | Black, other colours can be offered upon request. |

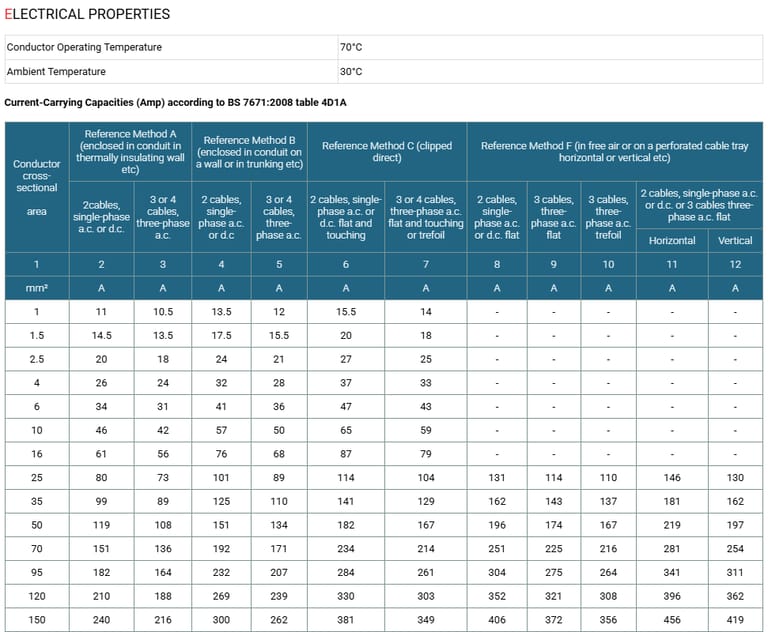

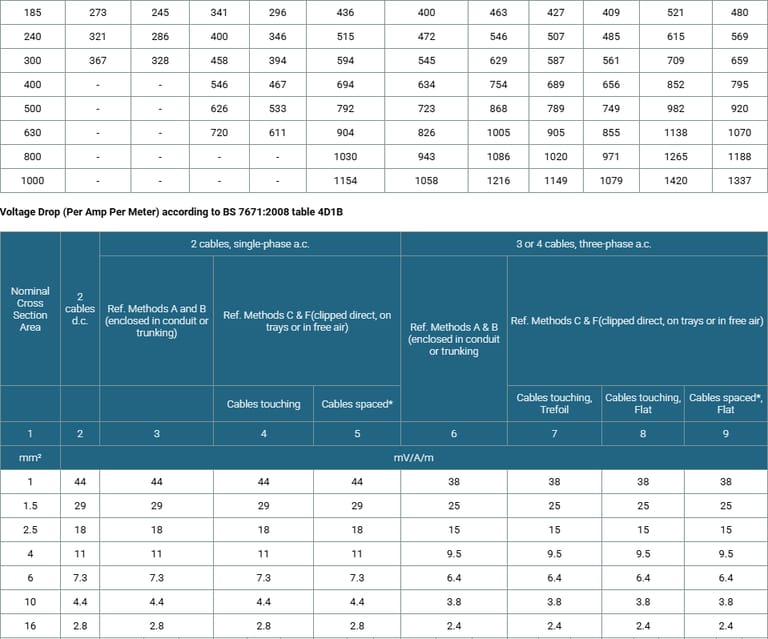

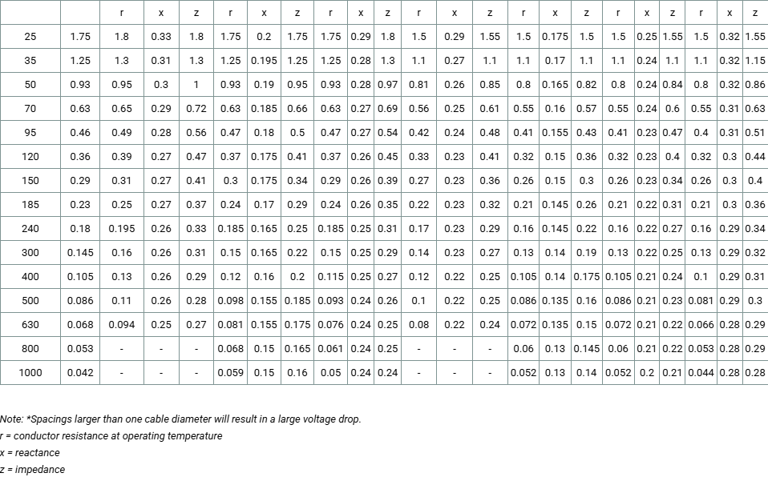

Mechanical and Electrical Properties

Maximum temperature range during operation | 70°C | |||||||||

Maximum short circuit temperature (5 Seconds) |

| |||||||||

| ||||||||||

Minimum bending radius |

| |||||||||

| ||||||||||

Construction Parameters

Conductor | FGD300 1RV-R | ||||

|---|---|---|---|---|---|

No. of Cores xCross Section | Class of Conductor | Nominal Insulation Thickness | Nominal Sheath Thickness | Nominal Overall Diameter | Approx. Weight |

No.xmm2 |

| mm | mm | mm | kg/km |

2 | 0.8 | 1.4 | 5.8 | 55 | |

2 | 0.8 | 1.4 | 6.2 | 70 | |

2 | 1 | 1.4 | 7.1 | 98 | |

2 | 1 | 1.4 | 7.6 | 124 | |

2 | 1 | 1.4 | 8.4 | 173 | |

2 | 1 | 1.4 | 9.3 | 240 | |

2 | 1.2 | 1.4 | 10.8 | 350 | |

2 | 1.2 | 1.4 | 11.9 | 468 | |

2 | 1.4 | 1.4 | 13.6 | 646 | |

2 | 1.4 | 1.4 | 15 | 854 | |

2 | 1.6 | 1.5 | 17.2 | 1154 | |

2 | 1.6 | 1.5 | 18.6 | 1428 | |

2 | 1.8 | 1.6 | 20.6 | 1764 | |

2 | 2 | 1.7 | 22.7 | 2160 | |

2 | 2.2 | 1.8 | 25.5 | 2796 | |

2 | 2.4 | 1.9 | 28.1 | 3449 | |

2 | 2.6 | 2 | 31.8 | 4570 | |

2 | 2.8 | 2.1 | 35 | 5641 | |

2 | 2.8 | 2.2 | 38.3 | 7015 | |

2 | 2.8 | 2.3 | 42.1 | 8798 | |

2 | 3 | 2.5 | 46.7 | 10970 | |

Introduction

In the realm of electrical engineering, power cables form the backbone of reliable energy distribution, particularly in developing economies like South Africa, where infrastructure demands are escalating amid challenges such as load-shedding and the shift towards renewable energy. Among these, 600/1000V PVC insulated PVC sheathed unarmoured power cables to IEC 60502-1 (single core) stand out for their versatility, cost-effectiveness, and compliance with international standards. These cables are designed for fixed installations in industrial settings, buildings, and similar applications, excluding direct burial in the ground or ducts. This article provides an in-depth analysis of their construction, mechanical and electrical properties, usage scenarios, and real-world applications, drawing on recent case studies from South Africa to illustrate their role in addressing local energy needs.

With South Africa's energy sector evolving rapidly—driven by the Integrated Resource Plan (IRP) and commitments to net-zero emissions by 2050—these low-voltage cables are pivotal in supporting both traditional and renewable infrastructure. Keywords such as IEC 60502-1, PVC insulation, unarmoured power cables, and current-carrying capacities will be explored to highlight their technical merits.

Usage Scenarios

Primarily for fixed installations in buildings and industrial areas, these cables excel in power distribution, lighting circuits, and machinery supply. Their unarmoured nature suits indoor conduits or trunking, avoiding exposure to abrasion.

In renewable energy, they facilitate onsite distribution from inverters to loads or grids. In mining, they power equipment under controlled conditions. Limitations include no direct burial, necessitating armoured alternatives for outdoor use.

In South Africa, amid Eskom's challenges, these cables support microgrids and backups, ensuring reliable supply during outages.

Case Studies from South Africa

Recent projects underscore their utility. In the Northern Cape solar farms (e.g., Droogfontein, Linde, Kalkbult, operational since around 2014 but with ongoing expansions as of 2025), Helukabel supplied over 200,000m of low-voltage cables, including PVC-insulated types compliant with IEC standards. These facilitated panel interconnections and distribution, addressing load-shedding by integrating renewable power. Outcomes included enhanced grid stability and reduced fossil fuel reliance, with capacities exceeding 50MW per farm.

The Oya Energy Hybrid Facility (Western Cape, 128MW, expected operational 2025) employs PV cables—often PVC-insulated for low-voltage segments—to harness wind and solar, with battery storage. Approved under RMIPPPP, it mitigates theft and intermittency, supplying clean energy at ~€77.87/MWh. Similarly, Umoyilanga (Northern/Eastern Cape, 75MW) uses analogous cables for hybrid setups, boosting mining sector reliability.

These cases, per 2021-2025 reports, highlight how IEC 60502-1 cables combat South Africa's energy crisis, though poor-quality imports (as warned in 2025 industry alerts) pose risks like fires.

Conclusion

The 600/1000V PVC insulated PVC sheathed unarmoured power cables to IEC 60502-1 exemplify engineering excellence, balancing cost, performance, and safety. Their detailed specifications enable robust applications, as evidenced in South African renewables. As the nation advances towards sustainable energy, these cables will remain integral, demanding continued innovation and quality assurance.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430