Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V, XLPE Insulated Cables according to IEC 60502-1

Application

These cables are used for electricity supply in low voltage installation system, They are suitable for installation in indoors and outdoors, in cable ducts, under ground, in power and switching stations, local energy distributions, industrial plants, where there is no risk of mechanical damage.

Construction

Conductors

The conductors shall be either of Class 1 or Class 2 of plain or metal-coated annealed copper or of plain aluminium or aluminium alloy, or of Class 5 of plain or metal-coated copper in accordance with IEC 60228.

Insulation

XLPE material and thickness shall be as per IEC 60502 or BS 5467 rated for 90°C continuous operation.

Colour Code

Colour Code (1)

1 Core | Red or Black |

2 Cores | Red, Black |

3 Cores | Red, Yellow, Blue |

4 Cores | Red, Yellow, Blue, Black |

5 Cores | Red, Yellow, Blue, Black, Green |

Above 5 Cores | Black Cores with White numerals |

Colour Code (2)

1 Core | Brown or Blue |

2 Cores | Brown, Blue |

3 Cores | Brown, Black, Grey |

4 Cores | Blue, Brown, Black, Grey |

5 Cores | Green/Yellow, Blue, Brown, Black, Grey |

Above 5 Cores | Black Cores with White numerals |

Other colours can be manufactured upon request.

Assembly / Inner Covering

The inner coverings may be extruded or lapped. For cables with circular cores, except cables with more than five cores, a lapped inner covering shall be permitted only if the interstices between the cores are substantially filled. A suitable binder is permitted before application of an extruded inner covering. The material is compatible with the insulating material,The materials used for inner coverings and fillers shall be suitable for the operating temperature of the cable and compatible with the insulating material.For halogen free cables, the inner covering and fillers shall also be halogen free compound.

Armour

Aluminum/galvanized steel/steel wires applied helically over the Inner Covering as per IEC 60502-1, or double aluminum/steel tapes and copper/tinned copper wire can also be manufactured upon request.

Outer Sheath

Outer sheath shall be of extruded PVC Type ST1/ST2 as per IEC 60502-1, Polyethylene type ST3/ST7, Halogen free compound ST8, Polychloroprene, chlorosulfonated polyethylene or similar polymers, type SE1 are also available on request.

Fire Performance of Cable Sheaths

Cables can be supplied with special flame retardant PVC outer sheath to comply with the flame test requirements of IEC 60332-3-22, IEC 60332-3-23 and IEC 60332-3-24, Halogen Free material comply to IEC60754-1/2 and IEC 60684-2.

What Are 600/1000V XLPE Insulated Cables?

At their core, 600/1000V XLPE insulated cables are designed for low-voltage electricity supply, rated for systems up to 1000 volts. The "600/1000V" designation indicates their suitability for earthed systems at 600V and unearthed at 1000V, making them versatile for various installations. XLPE, or cross-linked polyethylene, is the star material here – a thermoset polymer that's chemically cross-linked to enhance its properties over traditional PVC insulation.

Unlike PVC, which softens at higher temperatures, XLPE maintains integrity up to 90°C continuously, allowing for higher current-carrying capacity and better performance in demanding environments. These cables adhere to IEC 60502-1, an international standard that specifies requirements for power cables with extruded insulation for rated voltages from 1 kV to 30 kV, but our focus is on the low-voltage segment. This standard ensures consistency in design, testing, and performance, from conductor materials to fire safety.

In South Africa, where load shedding and infrastructure challenges are all too familiar, these cables play a vital role. For instance, in the Eskom grid expansion projects, XLPE cables have been deployed to reduce transmission losses and improve reliability, aligning with the country's Integrated Resource Plan for sustainable energy.

Applications

These cables shine in diverse settings, from indoor wiring to outdoor burials, avoiding mechanical risks.

In urban infrastructure, Johannesburg's City Power has utilised unarmoured multi-core cables (e.g., 4x150 mm²) for street lighting and substation connections. A 2023 case study from the Johannesburg Development Agency showed how XLPE cables reduced downtime by 30% during upgrades, thanks to their moisture resistance in rainy seasons.

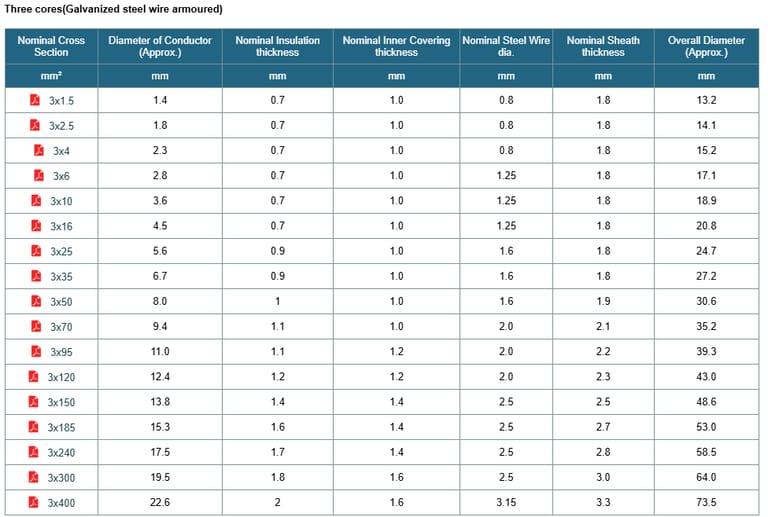

In renewable energy, the Jeffreys Bay Wind Farm in the Eastern Cape employs armoured three-core cables (3x240 mm²) for grounding and power distribution. The armour protects against wildlife and erosion, while XLPE's thermal stability handles variable loads from turbines. A report by the South African Wind Energy Association noted a 15% efficiency gain over older PVC cables.

Mining provides stark examples: At Anglo American's Kumba Iron Ore mine in the Northern Cape, single-core armoured cables (1x500 mm²) power heavy machinery. Their 90°C rating copes with underground heat, and IEC compliance ensures safety amid explosive risks. A 2024 incident analysis revealed that XLPE cables prevented a potential short-circuit disaster, saving millions in downtime.

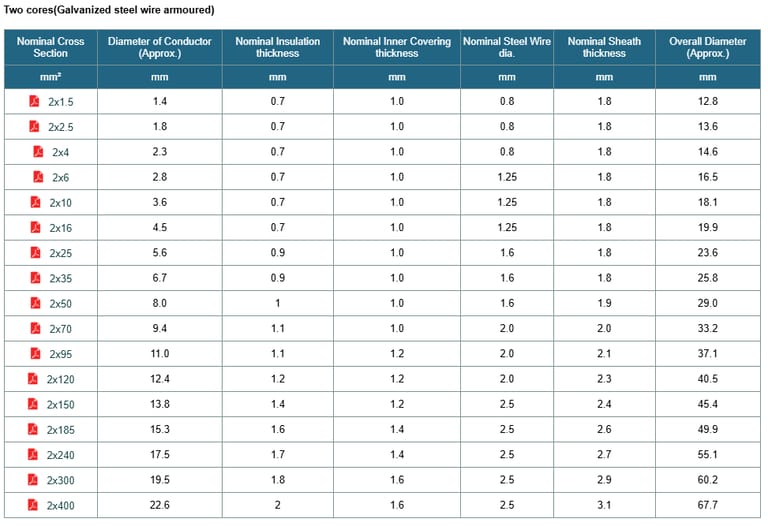

Industrial plants like ArcelorMittal's Vanderbijlpark steelworks use two-core galvanised steel wire armoured cables for switching stations. The helical armour withstands vibrations, and fire-retardant sheaths meet occupational health standards.

Even in residential areas, like Cape Town's suburbs, 600/1000V XLPE cables are buried underground for local distributions, offering longevity against coastal corrosion.

Advantages and Challenges

From an engineering perspective, XLPE cables excel in efficiency. Higher ampacity means smaller cross-sections for the same load, reducing material costs – vital in budget-constrained South African projects. Their low dielectric loss minimises energy waste, supporting the country's net-zero goals by 2050.

Environmentally, halogen-free options reduce toxic emissions, aligning with South Africa's Paris Agreement commitments. However, challenges include higher upfront costs compared to PVC and the need for specialised termination tools.

Economically, local manufacturers like CBI Electric produce these to IEC standards, boosting jobs in KwaZulu-Natal. A 2025 study by the Department of Trade, Industry and Competition estimates that adopting XLPE could cut national grid losses by 5%, saving billions in rand.

Safety-wise, the armour and fire ratings prevent hazards; in the Knysna fires of 2017, similar cables in rebuilt infrastructure proved resilient.

Frequently Asked Questions

What is the difference between armoured and unarmoured XLPE cables?

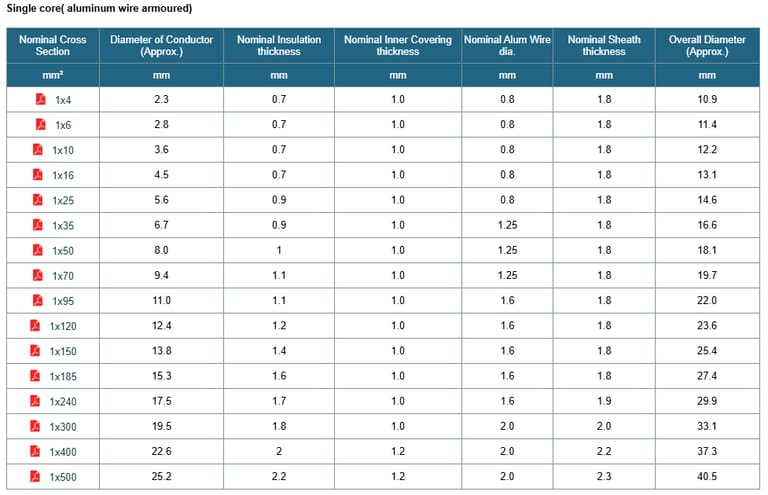

Unarmoured cables suit low-risk indoor/outdoor setups, like home wiring, with overall diameters from 5.6 mm (1x1.5 mm²) to 70.7 mm (4x400 mm²). Armoured versions add protection for underground or industrial use, increasing diameter (e.g., 10.9 mm for 1x4 mm² single-core) but enhancing durability against impacts.

How do I choose the right core configuration?

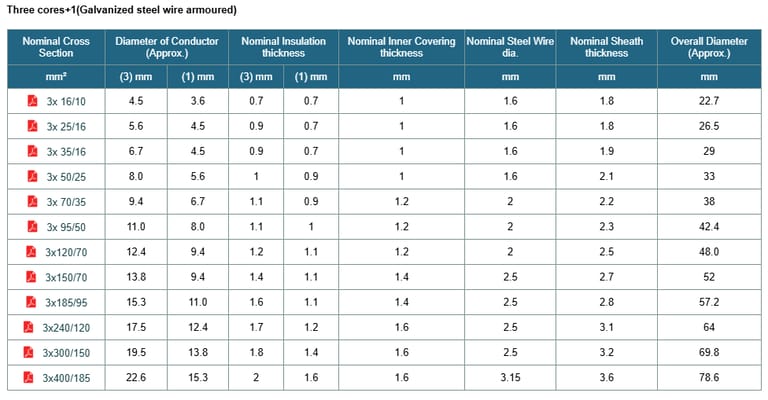

It depends on the application: single-core for high-current lines, two-core for simple phases, three-core for balanced systems, and multi-core (up to 61x2.5 mm²) for control circuits. In South Africa, three-core+1 (e.g., 3x150/70 mm²) is popular for earthed neutrals in mining.

Are these cables suitable for high-temperature environments?

Yes, XLPE's 90°C rating handles South Africa's heat waves. For fire safety, opt for IEC 60332-compliant sheaths.

What about installation in wet areas?

XLPE's moisture resistance makes it ideal for ducts or burials. In flood-prone Limpopo, armoured cables prevent water ingress.

Can colours be customised?

Absolutely, beyond standard codes, upon request – useful for colour-blind technicians or specific labelling in hospitals.

How do they compare to PVC cables?

XLPE offers better thermal and chemical resistance, longer life (up to 40 years), but at a premium price. In Eskom's rural electrification, this translates to fewer replacements.

Are there South African regulations to consider?

Yes, comply with SANS 1507 (harmonised with IEC) and NRS specifications for utility installations.

As South Africa transitions to renewables and smart grids, 600/1000V XLPE insulated cables per IEC 60502-1 will remain pivotal. Innovations like enhanced fire-retardants and recyclable materials could address environmental concerns. With case studies from mines to wind farms demonstrating their prowess, these cables aren't just wires – they're the lifelines powering our nation's progress.

In summary, from robust construction to versatile applications, these cables embody reliability. For South Africans facing energy challenges, investing in quality XLPE solutions ensures a brighter, more stable future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430