Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V XLPE Insulated, LSZH Sheathed, Armoured Power Cables to BS 6724 (2-5 Cores)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings. This product type is TUV approved.

STANDARDS

Basic design to BS 6724

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

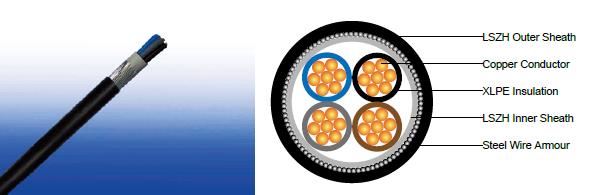

CABLE CONSTRUCTION

Conductor : Annealed copper wire, stranded according to BS EN 60228 class 2.

Insulation : XLPE type GP8 according to BS 7655-1.3. HEPR type GP6 according to BS 7655-1.2 or crosslinked polyolefin material type EI 5 according to BS EN 50363-5 can be offered as option.

Bedding : Extruded layer of polymeric material.

Armouring : Aluminium wire.

Outer Sheath : Extruded layer of polymeric material LTS 1 according to BS 7655-6.1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour :

2-core : Brown and blue.

3-core : Brown, black and grey.

4-core : Blue, brown, black and grey.

5-core : Green and yellow, blue, brown, black, grey.

Sheath Colour : Black; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius : 8 × Overall Diameter

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Air ambient temperature : 30°C

Ground ambient temperature : 20°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E4A

Conductor cross-ectional area | Ref. Method C (clipped direct) | Ref. Method E (in free air or on a perforated cable tray etc. horizontal or vertical) | Ref. Method D (direct in in groud or in ducting in groud. in or around buildings) | |||

|---|---|---|---|---|---|---|

1 two-core cable, single-phase a.c. or d.c. | 1 three- or four-core cable, three-phase a.c. | 1 two-core cable, single-phase a.c. or d.c. | 1 three- or four-core cable, three-phase a.c. | 1 two-core cable, single-phase a.c. or d.c. | 1 three- or four-core cable, three-phase a.c. | |

1 | 2 | 3 | 4 | 5 | 6 | 7 |

mm² | A | A | A | A | A | A |

1.5 | 27 | 23 | 29 | 25 | 25 | 21 |

2.5 | 36 | 31 | 39 | 33 | 33 | 28 |

4 | 49 | 42 | 52 | 44 | 43 | 36 |

6 | 62 | 53 | 66 | 56 | 53 | 44 |

10 | 85 | 73 | 90 | 78 | 71 | 58 |

16 | 110 | 94 | 115 | 99 | 91 | 75 |

25 | 146 | 124 | 152 | 131 | 116 | 96 |

35 | 180 | 154 | 188 | 162 | 139 | 115 |

50 | 219 | 187 | 228 | 197 | 164 | 135 |

70 | 279 | 238 | 291 | 251 | 203 | 167 |

95 | 338 | 289 | 354 | 304 | 239 | 197 |

120 | 392 | 335 | 410 | 353 | 271 | 223 |

150 | 451 | 386 | 472 | 406 | 306 | 251 |

185 | 515 | 441 | 539 | 463 | 343 | 281 |

240 | 607 | 520 | 636 | 546 | 395 | 324 |

300 | 698 | 599 | 732 | 628 | 446 | 365 |

400 | 787 | 673 | 847 | 728 | - | - |

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E4B

Conductor cross-sectional area | Two-core cable, d.c. | Two-core cable, single-phase a.c. | Three- or four-core cable, three-phase a.c. | ||||

|---|---|---|---|---|---|---|---|

1 | 2 | 3 | 4 | ||||

mm² | mV/A/m | mV/A/m | mV/A/m | ||||

1.5 | 31 | 31 | 27 | ||||

2.5 | 19 | 19 | 16 | ||||

4 | 12 | 12 | 10 | ||||

6 | 7.9 | 7.9 | 6.8 | ||||

10 | 4.7 | 4.7 | 4.0 | ||||

16 | 2.9 | 2.9 | 2.5 | ||||

|

| r | x | z | r | x | z |

25 | 1.85 | 1.85 | 0.160 | 1.90 | 1.60 | 0.140 | 1.65 |

35 | 1.35 | 1.35 | 0.155 | 1.35 | 1.15 | 0.135 | 1.15 |

50 | 0.98 | 0.99 | 0.155 | 1.00 | 0.86 | 0.135 | 0.87 |

70 | 0.67 | 0.67 | 0.150 | 0.69 | 0.59 | 0.130 | 0.60 |

95 | 0.49 | 0.50 | 0.150 | 0.52 | 0.43 | 0.130 | 0.45 |

120 | 0.39 | 0.40 | 0.145 | 0.42 | 0.34 | 0.130 | 0.37 |

150 | 0.31 | 0.32 | 0.145 | 0.35 | 0.38 | 0.125 | 0.30 |

185 | 0.25 | 0.26 | 0.145 | 0.29 | 0.22 | 0.125 | 0.26 |

240 | 0.195 | 0.200 | 0.140 | 0.24 | 0.175 | 0.125 | 0.21 |

300 | 0.155 | 0.160 | 0.140 | 0.21 | 0.140 | 0.120 | 0.185 |

400 | 0.120 | 0.130 | 0.140 | 0.190 | 0.115 | 0.120 | 0.165 |

Note :

r = conductor resistance at operating temperature

x = reactance

z = impedance

Introduction

In the heart of South Africa's bustling urban landscapes and industrial heartlands, where the hum of electricity powers everything from Johannesburg's skyscrapers to Cape Town's refineries, safety isn't just a buzzword—it's a lifeline. Imagine a fire breaking out in a crowded Gautrain station or a high-rise hospital ward; the difference between chaos and controlled evacuation could boil down to the humble power cable snaking through the walls. Enter the 600/1000V XLPE insulated, LSZH sheathed, armoured power cables compliant with BS 6724 standards for 2-5 cores. These aren't your run-of-the-mill wires; they're engineered marvels designed to withstand flames, crush loads, and the unforgiving South African climate, all while minimising toxic smoke that claims more lives than fire itself.

South Africa, with its mix of colonial-era buildings and cutting-edge developments, faces unique challenges: load-shedding woes, rising urban density, and stringent fire regulations under the National Building Regulations (SANS 10400). According to the South African Bureau of Standards (SABS), fire-related incidents in public infrastructure have surged by 15% since 2020, underscoring the need for cables that prioritise human life over mere conductivity. BS 6724 cables, featuring cross-linked polyethylene (XLPE) insulation, low smoke zero halogen (LSZH) sheathing, and robust aluminium wire armouring, rise to this call. TUV-approved and rooted in British Standards, they bridge global best practices with local demands, powering applications from power stations to petrochemical plants.

Fire Performance: The Silent Guardian in Crisis

Fire doesn't announce itself—it erupts. In confined spaces like Johannesburg's Carlton Centre or Durban's petrochem hubs, traditional PVC cables belch halogenated toxins, turning escape routes into gas chambers. BS 6724 cables flip the script with rigorous fire tests, proving their mettle under global scrutiny.

Flame retardance kicks off with IEC 60332-1-2/EN 60332-1-2: a single vertical cable withstands flame for 60 seconds without propagating. Scale to bundles via IEC 60332-3-24/EN 60332-3-24, where 3.5m lengths in a ladder rig resist fire spread—crucial for tray-installed runs in power stations.

The LSZH magic shines in emissions: IEC 60754-1/EN 50267-2-1 confirms zero halogen acidity; IEC 60754-2/EN 50267-2-2 measures pH >3 and conductivity <10µS/mm, meaning no corrosive hydrogen chloride to etch electronics. Smoke? IEC 61034-2/EN 61034-2 caps light obscuration at 60%—visibility stays, panic wanes.

These aren't lab tricks; they're lifesavers. In South Africa's 2023 Parliament fire, smoke from legacy cables hampered evacuation; BS 6724's low emissions could have bought precious minutes. TUV certification validates this, aligning with EU CPR Class C or better, now influencing SABS updates for public builds.

Rigorous testing ensures logical progression: single-core safety scales to multi-core resilience, making these cables indispensable where ventilation is a luxury, not a given.

Usage Scenarios: Powering South Africa's Diverse Landscape

These cables thrive where risk meets reliability. Power stations like Kusile demand armour for vibration, LSZH for control rooms packed with switchgear. Mass transit—Gautrain's tunnels—relies on low-smoke for passenger safety amid 100,000 daily riders. Airports like Cape Town International use them for baggage handling, where fire could cascade chaos.

Petrochemical plants (Sasol Secunda) need hydrocarbon-resistant sheaths against spills; hotels and hospitals (e.g., Netcare Christiaan Barnard) prioritise non-corrosive emissions for patient wards. High-rises like Ponte Tower? Armouring guards against seismic retrofits, XLPE handles heat from lifts.

In South Africa, SANS 10142 mandates them in escape routes; their 8x bend radius suits modular builds in informal settlements upgraded under REIPPPP. Economically, they're cost-effective: 20% pricier upfront but 40% lower lifecycle via reduced downtime.

From the Veld's power pulses to urban veins, 600/1000V XLPE insulated LSZH sheathed armoured power cables to BS 6724 embody South Africa's resilient spirit. Their layered defence—flame-retardant, smoke-scarce, mechanically unyielding—transforms specs into stories of survival. As 2025 unfolds with green energy pushes and smart city dreams, these cables will underpin it all, from renewables at Medupi to metros in eThekwini.

Yet, adoption hinges on us: specifiers, installers, policymakers. With SABS eyeing stricter LSZH mandates by 2026, now's the time to upgrade. These aren't just cables; they're commitments—to lives saved, assets preserved, and a nation electrified safely. In a land of contrasts, they bridge the gap, one core at a time.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430