Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

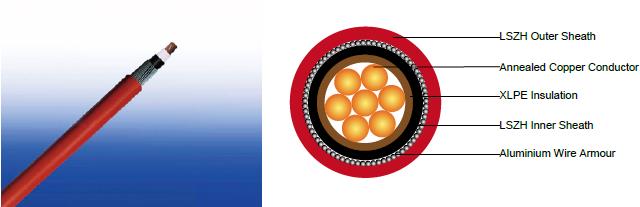

600/1000V XLPE Insulated, LSZH Sheathed, Armoured Power Cables to BS 6724 (Single Core)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings. This product type is TUV approved.

STANDARDS

Basic design to BS 6724

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

CABLE CONSTRUCTION

Conductor : Annealed copper wire, stranded according to BS EN 60228 class 2.

Insulation : XLPE type GP8 according to BS 7655-1.3. HEPR type GP6 according to BS 7655-1.2 or crosslinked polyolefin material type EI 5 according to BS EN 50363-5 can be offered as option.

Bedding : Extruded layer of polymeric material.

Armouring : Aluminium wire.

Outer Sheath : Extruded layer of polymeric material LTS 1 according to BS 7655-6.1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour : Brown or blue; other colours can be offered upon request.

Sheath Colour : Black; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius : 8 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FTX300 1RZ1MAZ1-R | ||||||

|---|---|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Nominal Bedding Thickness | Nominal AL Wire Armour Diameter | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | mm | mm | kg/km |

2 | 1.0 | 0.8 | 0.9 | 1.5 | 17.5 | 688 | |

2 | 1.1 | 0.8 | 1.25 | 1.5 | 20.2 | 941 | |

2 | 1.1 | 0.8 | 1.25 | 1.6 | 22.3 | 1244 | |

2 | 1.2 | 0.8 | 1.25 | 1.6 | 24.2 | 1524 | |

2 | 1.4 | 1.0 | 1.6 | 1.7 | 27.4 | 1853 | |

2 | 1.6 | 1.0 | 1.6 | 1.8 | 30.0 | 2292 | |

2 | 1.7 | 1.0 | 1.6 | 1.8 | 32.8 | 2925 | |

2 | 1.8 | 1.0 | 1.6 | 1.9 | 35.6 | 3612 | |

2 | 2.0 | 1.2 | 2.0 | 2.0 | 40.5 | 4653 | |

2 | 2.2 | 1.2 | 2.0 | 2.1 | 44.2 | 5779 | |

2 | 2.4 | 1.2 | 2.0 | 2.2 | 48.8 | 7341 | |

2 | 2.6 | 1.4 | 2.5 | 2.4 | 55.4 | 9364 | |

2 | 2.8 | 1.4 | 2.5 | 2.5 | 60.6 | 11644 | |

Introduction

In the realm of electrical engineering, the selection of appropriate power cables is crucial for ensuring safety, reliability, and efficiency in power distribution systems. Among the various types available, the 600/1000V XLPE insulated, LSZH sheathed, armoured power cables to BS 6724 (single core) stand out for their robust design and compliance with stringent safety standards. These cables are engineered to meet the demands of modern infrastructure, particularly in environments where fire safety and mechanical protection are paramount.

Developed in accordance with British Standard BS 6724, these cables incorporate cross-linked polyethylene (XLPE) insulation, low smoke zero halogen (LSZH) sheathing, and aluminium wire armouring. This combination not only enhances electrical performance but also minimises environmental and health risks during fire incidents. In South Africa, where rapid urbanisation and infrastructure development are ongoing, such cables play a vital role in powering critical facilities like power stations, airports, hospitals, and high-rise buildings.

Fire Performance and Safety Features

One of the standout features of these cables is their exceptional fire performance, making them ideal for high-risk environments. They comply with multiple IEC and EN standards:

Flame retardance: IEC 60332-1-2 / EN 60332-1-2 (single vertical wire test).

Reduced fire propagation: IEC 60332-3-24 / EN 60332-3-24 (bundled wires test).

Halogen-free: IEC 60754-1 / EN 50267-2-1.

No corrosive gas emission: IEC 60754-2 / EN 50267-2-2.

Minimum smoke emission: IEC 61034-2 / EN 61034-2.

These attributes are critical in confined spaces like underground transit systems or high-rise buildings, where smoke and toxic gases can exacerbate emergencies. In South Africa, where fire incidents in informal settlements and industrial sites are prevalent, LSZH sheathing reduces the risk of secondary hazards, aligning with national fire safety regulations.

The armouring adds another layer of safety by protecting against physical damage, ensuring circuit integrity during faults. Overall, these features position the cables as a preferred choice for safety-conscious installations.

Applications and Usage Scenarios

Primarily used in power stations, mass transit, airports, petrochemical plants, hotels, hospitals, and high-rise buildings, these cables excel where fire safety and armouring are essential. In power stations, they distribute power reliably; in airports, they support lighting and systems; in hospitals, they ensure uninterrupted supply; in high-rises, they handle vertical runs safely.

The 600/1000V XLPE insulated LSZH sheathed armoured power cables to BS 6724 represent a pinnacle of engineering, blending safety, efficiency, and adaptability. As South Africa continues its infrastructure push, these cables will remain integral to sustainable development.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430