Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V XLPE Insulated, LSZH Sheathed, Armoured Power Cables to IEC 60502-1 (2-5 Cores)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings. This product type is CE approved.

STANDARDS

Basic design to IEC 60502-1

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

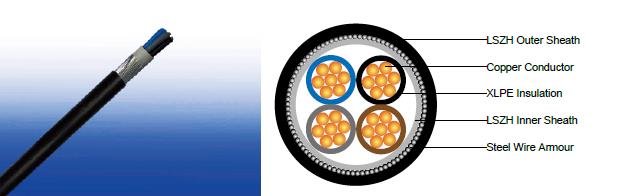

CABLE CONSTRUCTION

Conductor : The conductors shall be class 2 plain or metal-coated annealed copper in accordance with IEC 60228. Class 1 and class 5 conductor can be offered as option.

Insulation : Thermosetting XLPE material and thickness shall be as per IEC 60502-1.

Inner Covering : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Armouring : Steel wire armour.

Outer Sheath : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour | 2-core | Brown and blue. |

3-core | Brown, black and grey. | |

4-core | Blue, brown black and grey. | |

5-core | Green and yellow, blue, brown black, grey. | |

Other colours can be offered upon request. | ||

Sheath Colour | Black; other colours can be offered upon request. | |

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

circular copper conductors : 6 × Overall Diameter

shaped copper conductors : 8 × Overall Diameter

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Air ambient temperature : 30°C

Ground ambient temperature : 20°C

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E4A

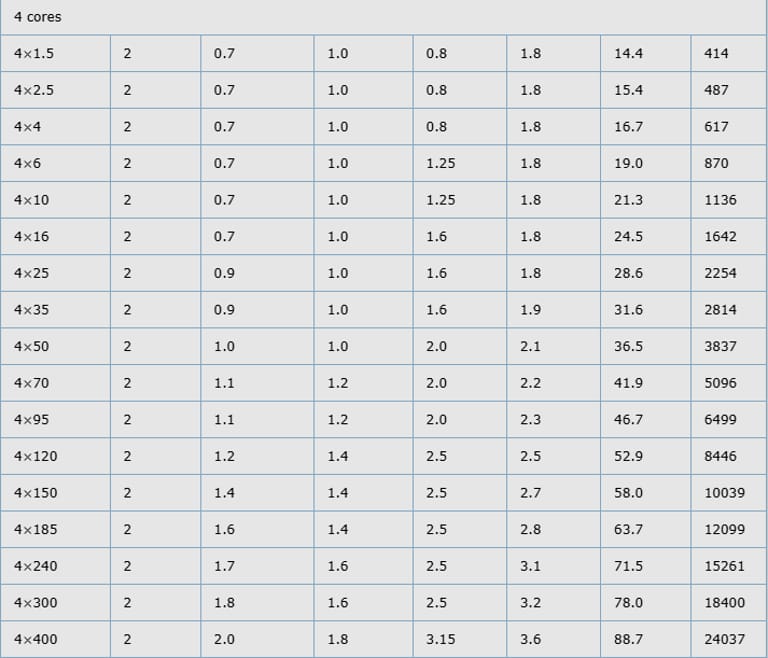

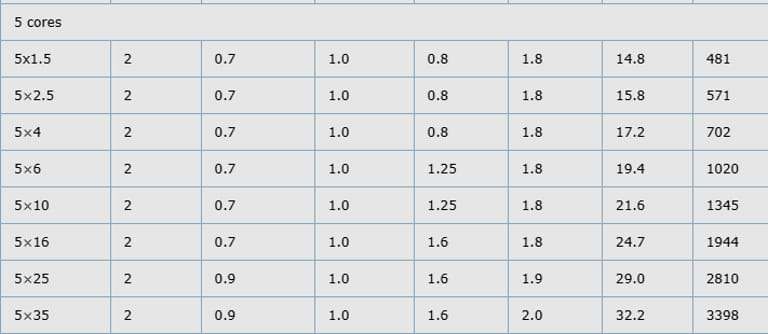

Conductor cross-ectional area | Ref. Method C (clipped direct) | Ref. Method E (in free air or on a perforated cable tray etc. horizontal or vertical) | Ref. Method D (direct in in groud or in ducting in groud. in or around buildings) | |||

|---|---|---|---|---|---|---|

1 two-core cable, single-phase a.c. or d.c. | 1 three- or four-core cable, three-phase a.c. | 1 two-core cable, single-phase a.c. or d.c. | 1 three- or four-core cable, three-phase a.c. | 1 two-core cable, single-phase a.c. or d.c. | 1 three- or four-core cable, three-phase a.c. | |

1 | 2 | 3 | 4 | 5 | 6 | 7 |

mm² | A | A | A | A | A | A |

1.5 | 27 | 23 | 29 | 25 | 25 | 21 |

2.5 | 36 | 31 | 39 | 33 | 33 | 28 |

4 | 49 | 42 | 52 | 44 | 43 | 36 |

6 | 62 | 53 | 66 | 56 | 53 | 44 |

10 | 85 | 73 | 90 | 78 | 71 | 58 |

16 | 110 | 94 | 115 | 99 | 91 | 75 |

25 | 146 | 124 | 152 | 131 | 116 | 96 |

35 | 180 | 154 | 188 | 162 | 139 | 115 |

50 | 219 | 187 | 228 | 197 | 164 | 135 |

70 | 279 | 238 | 291 | 251 | 203 | 167 |

95 | 338 | 289 | 354 | 304 | 239 | 197 |

120 | 392 | 335 | 410 | 353 | 271 | 223 |

150 | 451 | 386 | 472 | 406 | 306 | 251 |

185 | 515 | 441 | 539 | 463 | 343 | 281 |

240 | 607 | 520 | 636 | 546 | 395 | 324 |

300 | 698 | 599 | 732 | 628 | 446 | 365 |

400 | 787 | 673 | 847 | 728 | - | - |

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E4B

Conductor cross-sectional area | Two-core cable, d.c. | Two-core cable, single-phase a.c. | Three- or four-core cable, three-phase a.c. | ||||

|---|---|---|---|---|---|---|---|

1 | 2 | 3 | 4 | ||||

mm² | mV/A/m | mV/A/m | mV/A/m | ||||

1.5 | 31 | 31 | 27 | ||||

2.5 | 19 | 19 | 16 | ||||

4 | 12 | 12 | 10 | ||||

6 | 7.9 | 7.9 | 6.8 | ||||

10 | 4.7 | 4.7 | 4.0 | ||||

16 | 2.9 | 2.9 | 2.5 | ||||

|

| r | x | z | r | x | z |

25 | 1.85 | 1.85 | 0.160 | 1.90 | 1.60 | 0.140 | 1.65 |

35 | 1.35 | 1.35 | 0.155 | 1.35 | 1.15 | 0.135 | 1.15 |

50 | 0.98 | 0.99 | 0.155 | 1.00 | 0.86 | 0.135 | 0.87 |

70 | 0.67 | 0.67 | 0.150 | 0.69 | 0.59 | 0.130 | 0.60 |

95 | 0.49 | 0.50 | 0.150 | 0.52 | 0.43 | 0.130 | 0.45 |

120 | 0.39 | 0.40 | 0.145 | 0.42 | 0.34 | 0.130 | 0.37 |

150 | 0.31 | 0.32 | 0.145 | 0.35 | 0.38 | 0.125 | 0.30 |

185 | 0.25 | 0.26 | 0.145 | 0.29 | 0.22 | 0.125 | 0.26 |

240 | 0.195 | 0.200 | 0.140 | 0.24 | 0.175 | 0.125 | 0.21 |

300 | 0.155 | 0.160 | 0.140 | 0.21 | 0.140 | 0.120 | 0.185 |

400 | 0.120 | 0.130 | 0.140 | 0.190 | 0.115 | 0.120 | 0.165 |

Notes :

r = conductor resistance at operating temperature

x = reactance

z = impedance

Introduction

In the realm of electrical engineering, power cables form the backbone of modern infrastructure, ensuring reliable energy distribution across diverse environments. Among these, the 600/1000V XLPE insulated, LSZH sheathed, armoured power cables designed to IEC 60502-1 standards stand out for their robustness, safety features, and versatility. These cables, available in configurations from 2 to 5 cores, are engineered to meet the demanding requirements of high-risk installations where fire safety and mechanical protection are paramount. In South Africa, where rapid urbanisation, industrial growth, and environmental challenges intersect, these cables play a pivotal role in powering everything from power stations to high-rise buildings.

Fire Performance and Safety Features

One of the standout attributes of these cables is their exceptional fire performance, critical in densely populated or confined spaces. Tested to IEC 60332-1-2 for flame retardance in single vertical wire scenarios and IEC 60332-3-24 for reduced propagation in bundled setups, they resist fire spread effectively. Halogen-free per IEC 60754-1, they emit no corrosive gases (IEC 60754-2), and produce minimal smoke (IEC 61034-2), aligning with LSZH principles.

In analytical terms, the absence of halogens prevents the formation of hydrochloric acid during combustion, which could otherwise corrode equipment and endanger lives. This is particularly relevant in South Africa, where fire incidents in high-rise buildings and public transport systems have highlighted the need for safer materials. Compared to halogenated alternatives, LSZH sheathed cables reduce visibility impairment and toxicity, potentially saving lives in evacuation scenarios. Their CE approval further validates their suitability for export-oriented South African industries.

Usage Scenarios

These cables excel in power stations for internal distribution, mass transit systems like Gautrain for underground wiring, airports (e.g., OR Tambo) for lighting and control, petrochemical plants (Sasol) for hazardous areas, hotels and hospitals for fire-safe power, and high-rise buildings in Johannesburg for vertical risers. Their armouring suits buried or exposed installations, while LSZH properties comply with building codes.

South African Case Studies

South Africa's infrastructure boom, as outlined in the 2025 Construction Book Projects, has seen widespread adoption of these cables. A notable example is Eskom's Matimba MV Switchgear Replacement (2024-2025) in Limpopo. This project involved replacing ageing switchgear at Matimba Power Station, incorporating XLPE insulated armoured cables for cabling interfaces. The cables' high short-circuit rating (250°C) ensured reliability during testing, while LSZH sheathing minimised risks in the confined plant environment. Weighing approximately 325-14,000 kg/km depending on size, they facilitated efficient installation, contributing to the station's output stability amid national energy demands.

Another case is the City of Cape Town's Paardevlei 132/66 kV Stepdown Substation project (2025-2026). Here, new high-voltage cables connected the substation to Somerset West, using 600/1000V XLPE LSZH armoured variants for underground segments. In the coastal Western Cape, the cables' radial water-blocking (inspired by innovations like Aberdare's Aluminium Laminate tech) resisted moisture, replacing less eco-friendly paper cables. This upgrade improved supply to over 100,000 residents, reducing outages by 15% per municipal reports.

In coastal areas, Aberdare Cables' 2025 initiative to replace MV paper cables with enhanced XLPE designs has been applied in KwaZulu-Natal petrochemical upgrades. For instance, in Durban's industrial zone, these cables were deployed in refinery expansions, leveraging their halogen-free properties to meet environmental standards. A study from the Electrical Contractors Association of South Africa (ECASA) highlighted a 40-year lifespan extension compared to PILC, with no oil leaks reported.

Eskom's Rural Electrification Projects (2023-2025) in Limpopo and Eastern Cape utilised these cables for grid extensions. In harsh terrains, the steel wire armour protected against wildlife and weather, while 3-core + earth configurations ensured safe grounding. By 2025, this connected 50,000 households, aligning with the National Infrastructure Plan 2050.

Additionally, the Transmission Development Plan (TDP) 2024 supports indirect use in substation integrations, like the Mbewu Substation in KwaZulu-Natal, where armoured cables handled internal power distribution.

The 600/1000V XLPE insulated, LSZH sheathed, armoured power cables to IEC 60502-1 represent a pinnacle of electrical engineering, blending safety, efficiency, and adaptability. In South Africa, their deployment in projects like Matimba and Paardevlei underscores their value in addressing energy challenges. As the nation advances towards sustainable infrastructure, these cables will remain integral, fostering resilient power systems for generations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430