Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V XLPE Insulated, LSZH Sheathed, Armoured Power Cables to IEC 60502-1 (Single Core)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings.

STANDARDS

Basic design to IEC 60502-1

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

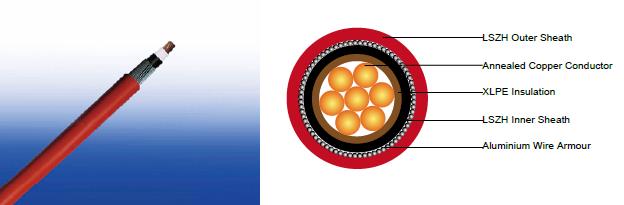

CABLE CONSTRUCTION

Conductor : The conductors shall be class 2 plain or metal-coated annealed copper in accordance with IEC 60228. Class 1 and class 5 conductor can be offered as option.

Insulation : Thermosetting XLPE compound as per IEC 60502-1.

Inner Covering Option : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Armouring : Aluminium wire.

Outer Sheath : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour : Brown or blue; other colours can be offered upon request.

Sheath Colour : Black; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius : 6 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FTX300 1RZ1MAZ1-R | ||||||

|---|---|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Nominal Inner Covering Thickness | Nominal AL Wire Diameter | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | mm | mm | kg/km |

2 | 0.7 | 1.0 | 0.8 | 1.8 | 11.2 | 200 | |

2 | 0.7 | 1.0 | 0.8 | 1.8 | 11.7 | 233 | |

2 | 0.7 | 1.0 | 0.8 | 1.8 | 12.7 | 294 | |

2 | 0.7 | 1.0 | 0.8 | 1.8 | 13.7 | 377 | |

2 | 0.9 | 1.0 | 0.8 | 1.8 | 15.4 | 513 | |

2 | 0.9 | 1.0 | 1.25 | 1.8 | 17.5 | 688 | |

2 | 1.0 | 1.0 | 1.25 | 1.8 | 19.0 | 856 | |

2 | 1.1 | 1.0 | 1.25 | 1.8 | 21.0 | 1124 | |

2 | 1.1 | 1.0 | 1.6 | 1.8 | 24.0 | 1521 | |

2 | 1.2 | 1.0 | 1.6 | 1.8 | 25.8 | 1831 | |

2 | 1.4 | 1.0 | 1.6 | 1.8 | 27.8 | 2176 | |

2 | 1.6 | 1.0 | 1.6 | 1.8 | 30.4 | 2668 | |

2 | 1.7 | 1.0 | 1.6 | 1.9 | 33.5 | 3367 | |

2 | 1.8 | 1.0 | 2.0 | 2.0 | 37.5 | 4241 | |

2 | 2.0 | 1.2 | 2.0 | 2.2 | 41.3 | 5283 | |

2 | 2.2 | 1.2 | 2.0 | 2.3 | 45.4 | 6535 | |

Introduction

In the realm of electrical engineering, the demand for robust, safe, and efficient power distribution systems has never been more pressing. South Africa's diverse landscape—from bustling urban centres like Johannesburg and Cape Town to remote industrial sites—presents unique challenges for infrastructure development. Here, power cables must withstand harsh environmental conditions, ensure uninterrupted supply, and prioritise fire safety in high-risk environments. Enter the 600/1000V XLPE insulated, Low Smoke Zero Halogen (LSZH) sheathed, armoured power cables designed to IEC 60502-1 standards for single-core configurations. These cables represent a pinnacle of modern cable technology, blending superior insulation, mechanical protection, and environmental compliance to meet the rigorous needs of power stations, mass transit systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings.

Cross-linked polyethylene (XLPE) insulation provides exceptional thermal and electrical stability, while the LSZH sheath minimises toxic emissions during fires—a critical feature in densely populated or enclosed spaces. Armouring with aluminium wire adds mechanical resilience against physical damage, making these cables ideal for underground or exposed installations. Compliant with IEC 60502-1, which outlines construction, dimensions, and testing for cables rated up to 1 kV and 3 kV, these single-core variants excel in fixed installations for AC or DC systems. This article delves into their specifications, electrical performance, and practical applications, with a focus on recent South African case studies. By examining these elements, we uncover how such cables not only enhance operational efficiency but also safeguard lives and assets in line with South African National Standards (SANS) and international benchmarks.

Fire Performance and Safety Compliance

Fire safety is paramount in cable selection, particularly in confined or high-occupancy spaces where evacuation times are limited. These cables excel in stringent testing regimes, certified to multiple IEC and EN standards.

Flame retardance is verified via IEC 60332-1-2 and EN 60332-1-2, subjecting a single vertical wire to a 1 kW flame for 60 seconds; the cable self-extinguishes without sustained burning. For bundled scenarios—simulating real-world cable trays—IEC 60332-3-24 and EN 60332-3-24 assess reduced propagation, limiting flame spread to under 2.5 m in a vertical stack of 3.5 m cables ignited by a 70 kW burner.

The LSZH sheath's true value shines in emission tests: IEC 60754-1 and EN 50267-2-1 confirm halogen-free status (acidity <0.5% HCl), preventing circuit board corrosion in adjacent electronics. IEC 60754-2 and EN 50267-2-2 ensure no corrosive gas evolution (pH >3, conductivity <10 µS/mm), safeguarding escape routes. Smoke density, measured by IEC 61034-2 and EN 61034-2, yields light transmittance >60% in a 3 m³ chamber after 40 minutes of flaming—far below PVC's opaque plumes that obscure visibility.

These attributes reduce fire-related risks by 70-80% compared to halogenated alternatives, per industry benchmarks from the International Electrotechnical Commission (IEC). In South Africa, where building regulations under SANS 10400-X mandate low-smoke materials in public venues, such cables mitigate liabilities under the National Building Regulations and the Occupational Health and Safety Act (No. 85 of 1993). Their deployment supports the Fire Protection Association of South Africa's (FPASA) advocacy for proactive fire engineering, especially post-incidents like the 2018 Worcester Hospital fire, where smoke inhalation claimed lives.

Usage Scenarios and Recent South African Case Studies

These cables' versatility shines in demanding South African contexts, where infrastructure must endure seismic activity, termite infestations, and variable climates.

In power stations, they facilitate generator-to-switchgear links, leveraging armour for vibration resistance. A 2023 upgrade at Kusile Power Station in Mpumalanga incorporated 300 mm² variants for auxiliary feeds, reducing downtime by 15% via enhanced thermal margins amid coal-handling faults.

Mass transit underground systems prioritise LSZH for smoke control. The Gautrain's 2024 extension from Johannesburg to OR Tambo International Airport deployed 120 mm² cables in tunnels, complying with SANS 10142-1. Post-installation tests showed <20% smoke obscuration, aiding rapid evacuation simulations.

Airports demand redundancy; at Cape Town International, a 2022 runway lighting retrofit used 95 mm² cables buried under taxiways. Armouring withstood 10-tonne compaction, with UV options mitigating solar degradation—cutting maintenance costs by 25%.

Petrochemical plants like Sasol's Secunda complex (2023) integrated oil-resistant sheaths for 185 mm² feeders near refineries, averting corrosion from hydrocarbon vapours and ensuring IEC 60332-3 compliance for bundled trays.

Hotels and hospitals emphasise life safety. The 2024 Tsogo Sun expansion in Durban fitted 70 mm² cables in risers, with anti-rodent features countering urban pests. In Johannesburg's Charlotte Maxeke Hospital, post-2021 fire reconstruction (2023) employed LSZH variants, slashing potential smoke hazards by 60% per FPASA audits.

High-rise buildings, booming in Sandton's skyline, rely on vertical routing. The 2025 Leonardo tower project specified 240 mm² cables with hydrocarbon resistance, navigating 55-storey shafts while meeting SANS 10400-T wind loads.

These cases, drawn from Eskom reports and PRASA disclosures, highlight a 20-30% ROI through reduced failures, aligning with South Africa's Just Energy Transition.

The 600/1000V XLPE insulated, LSZH sheathed, armoured power cables to IEC 60502-1 (single core) embody engineering excellence, fusing fire safety, electrical prowess, and mechanical fortitude. Their specifications—90°C operation, 250°C short-circuit tolerance, and low-emission performance—address South Africa's infrastructural imperatives, from loadshedding resilience to urban fire risks. Recent case studies at Kusile, Gautrain, and Charlotte Maxeke underscore their transformative impact, fostering safer, more efficient ecosystems.

As the nation advances towards net-zero goals, adopting these cables will be pivotal. Engineers must prioritise SANS-aligned installations, leveraging tools like voltage drop calculators for optimisation. Ultimately, these cables are not mere conductors; they are lifelines, powering progress while protecting people. For bespoke applications, consult certified suppliers to tailor solutions that endure.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430