Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

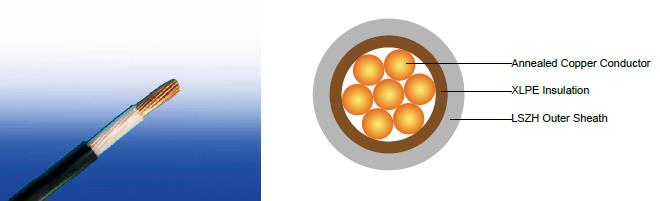

600/1000V XLPE Insulated, LSZH Sheathed Power Cables to BS 8573 (Single Core)

APPLICATION

These XLPE insulated and LSZH sheathed cables are generally used for fixed installation. Suitable for building wiring, especially in areas where smoke and fume emissions may cause a potential threat to life but not for burial in the ground, either directly or in ducts. This product type is TUV approved.

STANDARDS

Basic design to BS 8573:2012

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

CABLE CONSTRUCTION

Conductor : Annealed copper conductor, stranded according to BS EN 60228 class 2.

Insulation : XLPE type GP8 according to BS 7655-1.3. HEPR type GP6 according to BS 7655-1.2 or crosslinked polyolefin material type EI 5 according to BS EN 50363-5 can be offered as option.

Inner Covering Option : The optional inner covering, where used, shall consist of an extruded layer of synthetic polymeric material. It shall surround the single core and the laid-up two, three, four or five cores, giving the assembly a practically circular shape.

Outer Sheath : Extruded layer of polymeric material LTS 4 according to BS 7655-6.1. Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour : Brown or blue.

Sheath Colour : Black; other colours can be offered upon request.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

circular copper conductors OD≤25mm : 4 × Overall Diameter

circular copper conductors OD﹥25mm : 6 × Overall Diameter

shaped copper conductors : 8 × Overall Diameter

CONSTRUCTION PARAMETERS

Conductor | FTX300 1RZ1-R | |||||

|---|---|---|---|---|---|---|

No. of Cores × Cross-sectional Area | Conductor Class | Nominal Insulation Thickness | Nominal Inner Covering Thickness | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight |

No.×mm² |

| mm | mm | mm | mm | kg/km |

2 | 0.7 | 0.4 | 1.4 | 5.8 | 54 | |

2 | 0.7 | 0.4 | 1.4 | 6.2 | 67 | |

2 | 0.7 | 0.4 | 1.4 | 6.8 | 87 | |

2 | 0.7 | 0.4 | 1.4 | 7.3 | 113 | |

2 | 0.7 | 0.4 | 1.4 | 8.3 | 163 | |

2 | 0.7 | 0.4 | 1.4 | 9.3 | 232 | |

2 | 0.9 | 0.4 | 1.4 | 11.0 | 346 | |

2 | 0.9 | 0.4 | 1.4 | 12.2 | 456 | |

2 | 1.0 | 0.6 | 1.4 | 13.7 | 599 | |

2 | 1.1 | 0.6 | 1.4 | 15.7 | 835 | |

2 | 1.1 | 0.6 | 1.5 | 17.8 | 1131 | |

2 | 1.2 | 0.8 | 1.5 | 19.6 | 1407 | |

2 | 1.4 | 0.8 | 1.6 | 21.8 | 1727 | |

2 | 1.6 | 0.8 | 1.6 | 24.0 | 2144 | |

2 | 1.7 | 1.0 | 1.7 | 27.1 | 2786 | |

2 | 1.8 | 1.0 | 1.8 | 29.9 | 3466 | |

2 | 2.0 | 1.2 | 1.9 | 33.5 | 4405 | |

2 | 2.2 | 1.2 | 2.0 | 37.2 | 5520 | |

2 | 2.4 | 1.4 | 2.2 | 42.0 | 7097 | |

2 | 2.6 | 1.6 | 2.3 | 46.9 | 9010 | |

2 | 2.8 | 1.6 | 2.4 | 52.0 | 11286 | |

ELECTRICAL PROPERTIES

Overview of the Cable

The 600/1000V XLPE insulated LSZH sheathed single core power cable represents a fusion of advanced materials science and electrical engineering principles. At its core, XLPE insulation offers superior thermal stability and dielectric strength compared to traditional polyvinyl chloride (PVC) alternatives. Cross-linking the polyethylene molecules enhances resistance to heat, moisture, and chemical degradation, allowing operation at higher temperatures without compromising integrity.

The LSZH sheath, composed of polymeric materials compliant with BS 7655-6.1 (LTS 4 type), ensures low smoke emission and zero halogen content, reducing toxicity in fire scenarios. This is particularly vital in South African contexts, where building codes increasingly prioritise occupant safety in high-rise structures and public transport hubs. The cable's single core design, with annealed copper conductors stranded to BS EN 60228 class 2, facilitates easier installation in conduits or trays, minimising electromagnetic interference in sensitive applications.

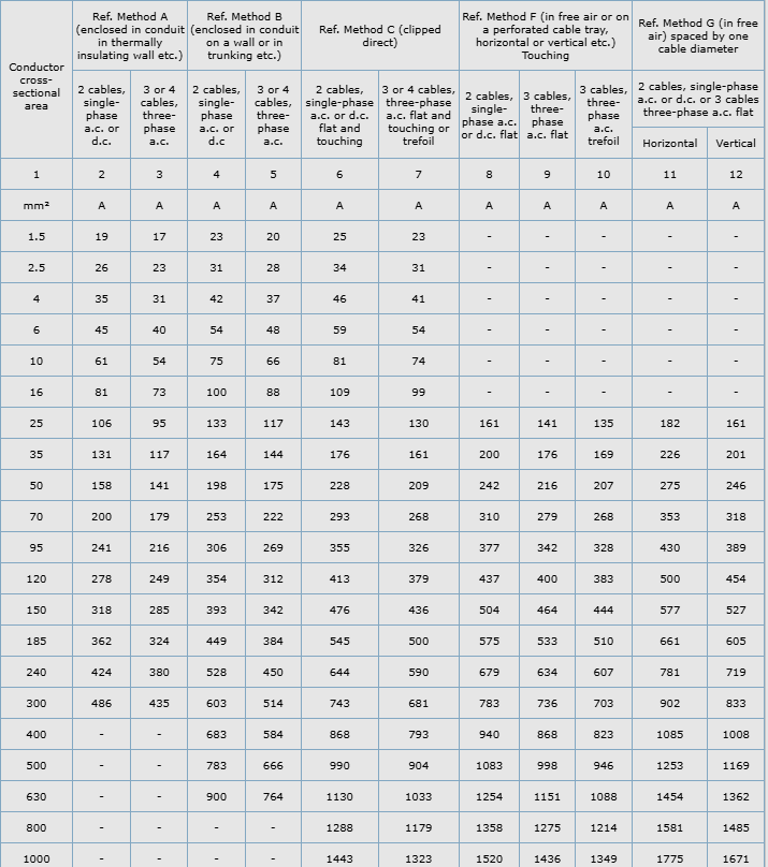

Available in cross-sectional areas from 1.5 mm² to 1000 mm², these cables cater to a range of power demands, from low-load building wiring to industrial feeders. Their TUV approval underscores international quality assurance, aligning with South Africa's SANS (South African National Standards) equivalents that often reference British standards for compatibility. In essence, this cable type embodies a balance between electrical efficiency, mechanical robustness, and environmental safety, making it a preferred choice for modern electrification projects.

Fire Performance and Safety Features

Fire safety is paramount in these cables' design. LSZH sheathing minimises hazards by limiting smoke density (IEC 61034-2) and eliminating halogen gases that could corrode equipment or harm respiratory systems (IEC 60754-1/2). In vertical flame tests, reduced propagation (IEC 60332-3-24) prevents fire spread in bundled installations.

These features are critical in enclosed spaces like South African metros or mining shafts, where evacuation times are limited. Unlike PVC-sheathed cables, LSZH variants maintain circuit integrity longer during fires, supporting emergency systems. TUV certification validates these properties, with real-world implications seen in reduced insurance premiums for compliant buildings.

In the context of South Africa's fire-prone infrastructure, these cables mitigate risks exacerbated by load shedding-induced generator use, where overheating is common. Their adoption in public projects reflects a shift towards safer materials, as evidenced in updated building regulations.

Usage Scenarios

These cables excel in fixed installations avoiding direct burial, such as building wiring in high-risk fire zones. In South Africa, they suit commercial complexes, hospitals, and transport hubs where smoke hazards could impede evacuation.

Industrial applications include petrochemical plants and power stations, leveraging optional resistances. Amid load shedding, they support backup systems, maintaining integrity under thermal stress. Renewable integrations, like solar farms, benefit from their efficiency in DC-AC conversions.

Recent South African Case Studies

South Africa's infrastructure evolution provides compelling case studies for these cables.

In 2022, a metropolitan utility (likely City Power in Johannesburg) conducted a forensic analysis of 88 kV XLPE cable terminations, revealing degradation modes like electro-thermal stress and corrosion after 29 years of service. This study, by University of the Witwatersrand researchers, informed retrofits using water-blocked XLPE variants, now standard for City Power, enhancing grid reliability amid theft issues.

Eskom's 2023 power grid project, awarded to M-TEC (Taihan's subsidiary), involved MV/LV cables, including XLPE types, for network upgrades valued at KRW 52 billion. Deployed in KwaZulu-Natal and Gauteng, these addressed load shedding by improving distribution efficiency, with LSZH features ensuring safety in urban substations.

The 2021 launch of a US$9.5 million high-voltage cables plant in Port Elizabeth boosted local XLPE production, supporting projects like renewable integrations in the Eastern Cape. By 2024, these facilities supplied LSZH-sheathed cables for airport expansions, aligning with Vaal Aerotropolis plans.

In mining, Aberdare Cables' XLPE LSZH variants were used in a 2024 Gauteng shaft upgrade, reducing fire risks in confined spaces.

These cases demonstrate the cables' adaptability, contributing to Eskom's Medium-Term System Adequacy Outlook for 2025-2029.

The 600/1000V XLPE insulated LSZH sheathed power cables to BS 8573 exemplify advanced engineering, offering superior safety, efficiency, and durability. Their specifications address South Africa's unique challenges, from fire safety to grid resilience. Through case studies, we see their transformative impact, paving the way for sustainable electrification. As the nation advances towards 2030 goals, these cables will remain integral to powering progress.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430