Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

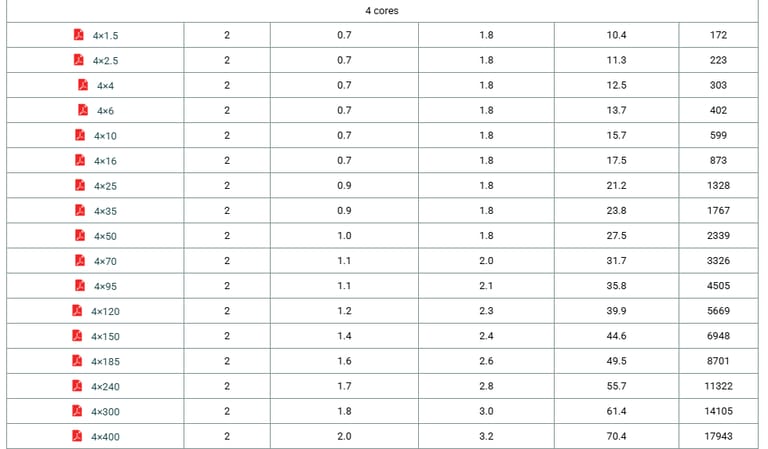

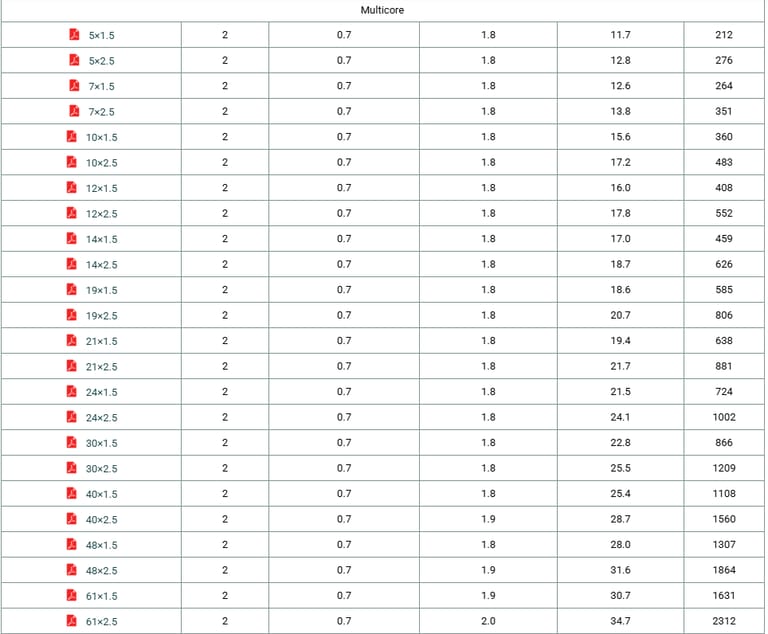

600/1000V XLPE Insulated, LSZH Sheathed Power Cables to IEC 60502-1 (2-5 Cores & Multicore)

APPLICATION

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals and high-rise buildings. This product type is CE approved.

STANDARDS

Basic design to IEC 60502-1

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

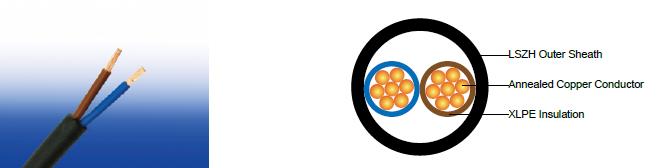

CABLE CONSTRUCTION

Conductor : The conductors shall be class 2 plain or metal-coated annealed copper in accordance with IEC 60228. Class 1 and class 5 conductor can be offered as option.

Insulation : Thermosetting XLPE material and thickness shall be as per IEC 60502-1.

Outer Sheath : Thermoplastic halogen free compound ST8 as per IEC 60502-1.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

COLOUR CODE

Insulation Colour | 2-core | Brown and blue. |

3-core | Brown, black and grey. | |

4-core | Blue, brown black and grey. | |

5-core | Green and yellow, blue, brown black, grey. | |

Above 5 Cores | Black cores with white numerals. | |

Other colours can be offered upon request. | ||

Sheath Colour | Black; other colours can be offered upon request. | |

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius :

circular copper conductors OD≤25mm : 4 × Overall Diameter

circular copper conductors OD﹥25mm : 6 × Overall Diameter

shaped copper conductors : 8 × Overall Diameter

Introduction: Powering Progress with Safer Cables

In the heart of South Africa's bustling urban landscapes and industrial hubs, where load shedding has long cast shadows over progress, the quest for reliable, safe electrical infrastructure has never been more urgent. Enter the 600/1000V XLPE insulated LSZH sheathed power cables to IEC 60502-1 (2-5 cores and multicore) – a technological marvel that's quietly transforming how we distribute power in critical environments. These cables aren't just wires; they're lifelines designed to withstand the harshest conditions while prioritising human safety.

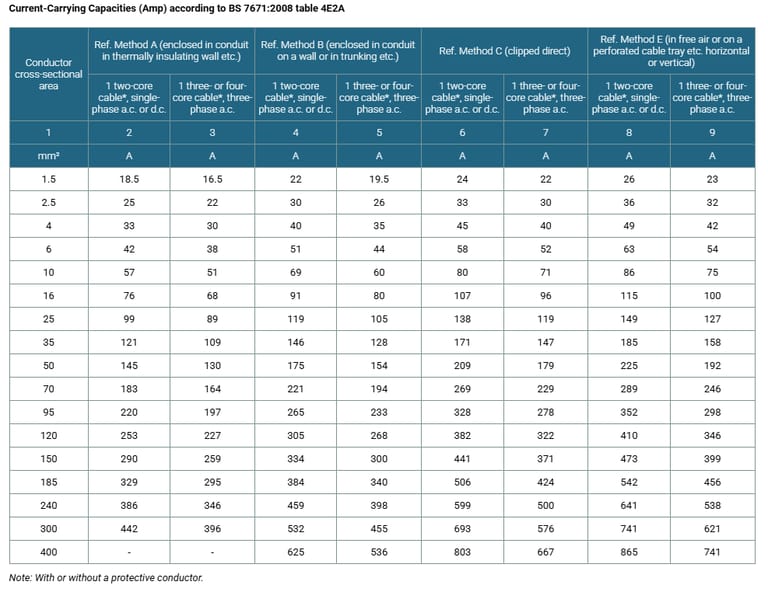

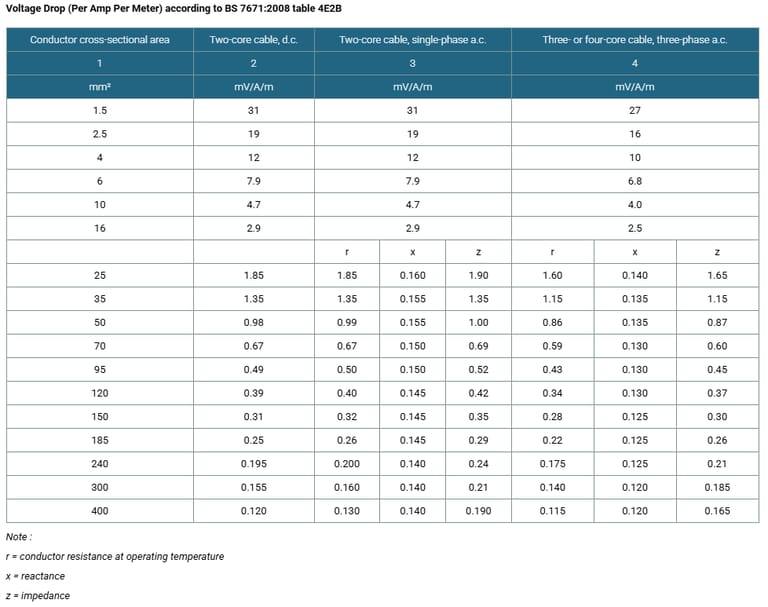

Cross-linked polyethylene (XLPE) insulation provides robust thermal and electrical stability, while the low smoke zero halogen (LSZH) sheath minimises toxic emissions during fires, aligning perfectly with South Africa's stringent fire safety regulations under the National Building Regulations (SANS 10400) and the Occupational Health and Safety Act. Compliant with the international IEC 60502-1 standard, these cables are rated for 600/1000V, making them ideal for low-voltage applications in power stations, mass transit systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings.

Fire Performance: Engineering Safety into Every Metre

Fire doesn't announce itself – it erupts, demanding cables that fight back. These XLPE LSZH cables shine here, passing a battery of IEC and EN tests that simulate real infernos.

Start with flame retardance: IEC 60332-1-2 (single vertical wire test) ensures a single cable won't propagate flames beyond 60 seconds. For bundled scenarios, IEC 60332-3-24 (vertically-mounted) limits fire spread to 2.5m in a 1m³ chamber, critical for conduit-packed walls in high-rises.

Halogen-free status (IEC 60754-1; EN 50267-2-1) means no corrosive gases – pH stays above 3, conductivity below 10µS/mm – protecting sensitive electronics like hospital ventilators or airport radar from acid corrosion. Smoke emission is capped at 60% light obscuration (IEC 61034-2; EN 61034-2), visibility remains for safe evacuation.

In South Africa, where SANS 10142-1 (Wiring of Premises) mandates low-smoke materials in public spaces, these specs exceed requirements. Consider the 2021 Parliament fire in Cape Town: smoke from PVC cables hampered escape. LSZH cables could have mitigated that, underscoring their role in national fire strategy.

Thermally, 90°C max operation suits ambient 30°C installs, with short-circuit tolerance preventing cascading failures. Options like hydrocarbon resistance suit petrochemical plants, where oil spills are risks.

Logically, this fire triad – retardance, low toxicity, minimal smoke – forms a safety net. It's not just compliance; it's lifesaving science, reducing fatality risks by up to 70% in confined spaces, per global studies adapted to local data.

Usage Scenarios: Tailored for South Africa's Challenges

Power stations demand reliability amid heat; these cables' 90°C rating suits Kusile's turbines. Mass transit like Gautrain tunnels benefits from LSZH – no smoke choking evacuations. Airports (OR Tambo) use multicore for radar feeds, hydrocarbon options for fuel zones.

Petrochemicals (Sasol Secunda) leverage oil resistance; hotels and hospitals prioritise low toxicity for guest/patient safety. High-rises, booming in Cape Town's waterfront, install 4x185mm² for lifts, bending radii accommodating tight shafts.

In renewables, they link solar farms to grids, UV sheaths weathering Karoo sun. Anti-termite options guard against veld pests.

Logically, selection hinges on load, environment, and regs: calculate ampacity, derate for grouping, verify drops. They're versatile, but specs dictate fit.

The 600/1000V XLPE insulated LSZH sheathed power cables to IEC 60502-1 aren't mere components; they're South Africa's shield against electrical vulnerabilities. From flame-retardant prowess to precise electricals, they embody innovation tailored to local needs – powering growth without peril.

As urbanisation hits 70% by 2030 and renewables surge, mandating these in regs could slash fire losses (R10bn annually). Engineers, specify wisely; policymakers, prioritise. In Mzansi's rainbow of challenges, these cables colour a brighter, safer grid.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430