Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V XLPE Insulated, LSZH Sheathed Power Cables to IEC 60502-1 (Triple Core)

APPLICATION

These cables are used in low voltage power distribution networks. Special application in places with poor ventilation, direct application in places with public attendance high. They can be installed in ducts, ladders or cable trays, in dry, humid or wet environments.

STANDARDS

IEC 60228

IEC 60502-1

FIRE PERFORMANCE

Flame Retardance (Single vertical wire or cable test) | IEC 60332-1-2; EN 60332-1-2 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cables test) | IEC 60332-3-24; EN 60332-3-24 |

Halogen Free | IEC 60754-1; EN 50267-2-1 |

No Corrosive Gas Emission | IEC 60754-2; EN 50267-2-2 |

Minimum Smoke Emission | IEC 61034-2; EN 61034-2 |

VOLTAGE RATING

600/1000V

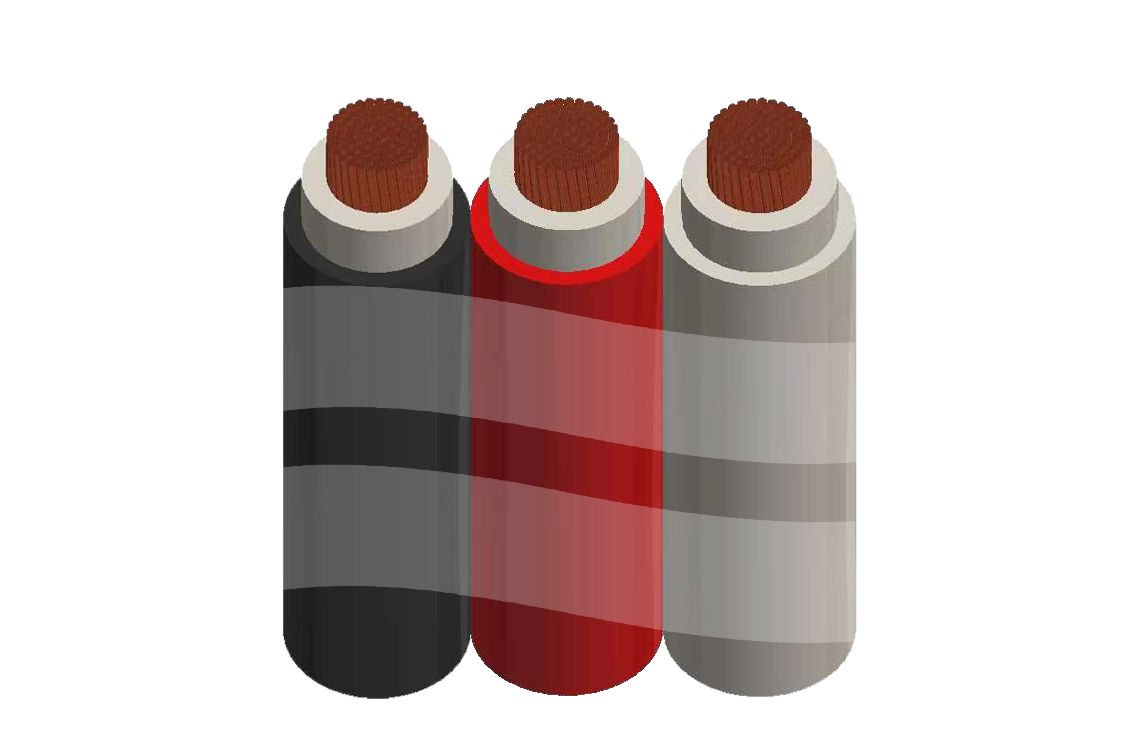

CABLE CONSTRUCTION

Conductor : Flexible copper, class 2.

Insulation : Cross linked polyethylene XLPE.

Outer Sheath : Halogen free thermoplastic compound HFFR.

Outer Sheath Option : UV resistance, hydrocarbon resistance, oil resistance, anti-rodent and anti-termite properties can be offered as option.

Tape : Polyester tape.

COLOUR CODE

Insulation Colour : Natural.

Sheath Colour : Black, red and white or black, red and blue.

PHYSICAL AND THERMAL PROPERTIES

Maximum temperature range during operation : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Overload maximum core temperature : 130°C

CONSTRUCTION PARAMETERS

Conductor | FTX300 1RZ1-R / N2XOH | |||||

|---|---|---|---|---|---|---|

No. of Cores × Cross- sectional Area | Conductor Class | Conductor Diam | Min. Insulation Thick | Min. Outer Sheath Thick | Approx. Overall Diameter | Approx. Weight |

No.×mm² | mm | mm | mm | mm | kg/km | |

10 | 2 | 4.1 | 0.7 | 0.9 | 7.7×22.7 | 393 |

16 | 2 | 5.3 | 0.7 | 0.9 | 8.8×26.0 | 565 |

25 | 2 | 6.6 | 0.9 | 0.9 | 10.5×31.2 | 845 |

35 | 2 | 7.8 | 0.9 | 0.9 | 11.7×34.8 | 1127 |

50 | 2 | 9.3 | 1.0 | 0.9 | 13.5×40.2 | 1571 |

70 | 2 | 11.3 | 1.1 | 1.0 | 15.8×47.1 | 2171 |

95 | 2 | 12.8 | 1.1 | 1.0 | 17.4×51.9 | 2769 |

120 | 2 | 14.5 | 1.2 | 1.1 | 19.5×58.2 | 3550 |

150 | 2 | 16.2 | 1.4 | 1.2 | 21.8×65.1 | 4286 |

185 | 2 | 18.0 | 1.6 | 1.2 | 24.0×71.7 | 5214 |

240 | 2 | 20.7 | 1.7 | 1.2 | 26.9×80.4 | 6813 |

300 | 2 | 23.2 | 1.8 | 1.3 | 29.9×89.3 | 8419 |

400 | 2 | 26.5 | 2.0 | 1.5 | 34.0×101.6 | 11109 |

500 | 2 | 30.3 | 2.2 | 1.6 | 38.5×115.1 | 14387 |

ELECTRICAL PROPERTIES

Conductor operating temperature : 90°C

Ambient temperature : 30°C

Conductor Cross- sectional area | Max. DC Resist. Cond. 20°C | Perm. Current Buried/Duct 20°C | Perm. Current Rating In Air 30°C - flat formation | Current Rating In Air 30°C - trefoil | Nominal Capacitance |

|---|---|---|---|---|---|

mm² | Ohm/km | A | A | A | pF/m |

10 | 1.91 | 58 | 77 | 74 | 445 |

16 | 1.21 | 75 | 105 | 101 | 593 |

25 | 0.78 | 96 | 141 | 135 | 549 |

35 | 0.554 | 115 | 176 | 169 | 637 |

50 | 0.386 | 135 | 216 | 207 | 682 |

70 | 0.272 | 167 | 279 | 268 | 750 |

95 | 0.206 | 197 | 342 | 328 | 840 |

120 | 0.161 | 223 | 400 | 383 | 873 |

150 | 0.129 | 251 | 464 | 444 | 843 |

185 | 0.108 | 281 | 533 | 510 | 803 |

240 | 0.0801 | 324 | 634 | 607 | 866 |

300 | 0.0641 | 365 | 736 | 703 | 916 |

400 | 0.0486 | 426 | 868 | 823 | 944 |

500 | 0.0384 | 481 | 998 | 946 | 983 |

Introduction

In the evolving landscape of electrical infrastructure, particularly in regions like South Africa where urbanisation and industrial growth intersect with stringent safety regulations, the demand for advanced cabling solutions has never been more pressing. Among these, 600/1000V XLPE (cross-linked polyethylene) insulated, LSZH (low smoke zero halogen) sheathed triple core power cables, designed to IEC 60502-1 standards, stand out for their balance of performance, safety, and versatility. These cables are pivotal in low-voltage power distribution networks, ensuring efficient energy delivery while minimising risks in high-occupancy environments.

XLPE insulation provides superior thermal stability and electrical integrity, allowing operation at elevated temperatures without degradation. The LSZH sheath, meanwhile, addresses a critical concern in fire-prone settings by reducing smoke emission and eliminating corrosive halogen gases during combustion. Compliant with IEC 60502-1, these cables meet global benchmarks for power cables rated up to 1 kV, incorporating features like flame retardance and low smoke propagation as per IEC 60332 and IEC 61034 standards. In South Africa, where public buildings, mining operations, and rural electrification projects face unique challenges—from load shedding to harsh environmental conditions—these cables have become integral to modernising grids.

Fire Performance and Safety Features

Fire safety is paramount for LSZH sheathed cables, distinguishing them in scenarios where human life hinges on rapid egress. These cables pass IEC 60332-1-2, withstanding a 1 kW flame for 60 seconds without igniting beyond 50 mm, and IEC 60332-3-24 Category C, limiting propagation in bundled setups to 2.5 m/min. Halogen-free per IEC 60754-1 (acidity <0.5% HCl equivalent), they emit no corrosive gases under IEC 60754-2, preserving adjacent equipment during blazes.

Smoke emission is curtailed to <60% light obscuration per IEC 61034-2, slashing visibility loss and toxic inhalation risks—vital in enclosed South African metrorail systems or hospitals. This contrasts sharply with PVC cables, which can release up to 20% halogens, exacerbating acid rain-like corrosion in fires.

In South Africa, where building codes under the National Building Regulations (SANS 10400-T) mandate low-smoke materials in public assemblies, these features ensure compliance. Enhanced options like anti-termite sheaths further bolster longevity in biodiversity hotspots.

Usage Scenarios in South Africa

These cables thrive in South Africa's multifaceted environments: from Johannesburg's subterranean malls to Cape Town's coastal humidity. In public buildings like schools and hospitals, LSZH properties safeguard occupants during evacuations, installed in trays for easy retrofits. Poorly ventilated tunnels, such as Gautrain stations, benefit from their low propagation rates, preventing fire spread in confined spaces. Industrial ducts in mining ops handle wet conditions, with UV options for exposed ladders. Rural grids employ larger cores for long hauls, derated for 40°C ambients.

600/1000V XLPE insulated, LSZH sheathed triple core power cables to IEC 60502-1 epitomise innovation in safe, efficient distribution. Their specs, from low resistance to fire resilience, align seamlessly with South African needs, as evidenced in recent deployments. As infrastructure expands, these cables will underpin a more secure energy future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430