Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V XLPE Insulated, PVC Sheathed, Armoured Power Cables to BS 5467 (2-5 Cores)

Application

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. This product type is TUV approved.

Standards

Basic design to BS 5467

Approvals

TUV Certification (Z1 17 01 98200 003)

Fire Performance

Flame Retardance (Single Vertical Wire Test) | BS EN 60332-1-2 |

Voltage Rating

600/1000V

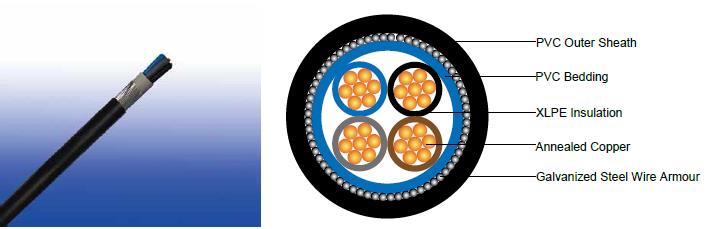

Cable Construction

Conductor | Annealed copper wire, stranded according to BS EN 60228 class 2. |

Insulation | Extruded XLPE GP 8 according to BS 7655-1.3. |

Bedding | PVC. |

Armouring | Galvanized steel wire |

Outer Sheath | PVC Type 9 according to BS 7655-4.2. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3,UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Two-core: Brown, blue |

Sheath Colour | Black, other colours can be offered upon request. |

Physical AND THERMAL PROPERTIES

Maximum temperature range during operation (XLPE) | 90°C |

Maximum short circuit temperature (5 Seconds) | 250°C |

Minimum bending radius | 8 x Overall Diameter |

ELECTRICAL PROPERTIES

Conductor Operating Temperature | 90°C |

Ambient Temperature | 30°C |

Current-Carrying Capacities (Amp) according to BS7671:2008 table 4E4A

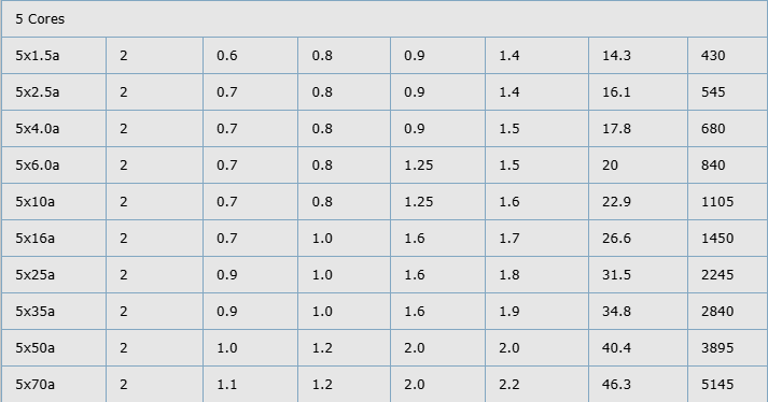

Conductor crosssectional | Reference Method C (clipped direct) | Reference Method E (in free air | Reference Method D (direct in in | |||

|---|---|---|---|---|---|---|

1 two-core cable*, | 1 three-or four | 1 two-core | 1 three-or four | 1 two-core cable*, | 1 three-or four | |

1 | 2 | 3 | 4 | 5 | 6 | 7 |

mm2 | A | A | A | A | A | A |

1.5 | 27 | 23 | 29 | 25 | 25 | 21 |

2.5 | 36 | 31 | 39 | 33 | 33 | 28 |

4.0 | 49 | 42 | 52 | 44 | 43 | 36 |

6.0 | 62 | 53 | 66 | 56 | 53 | 44 |

10 | 85 | 73 | 90 | 78 | 71 | 58 |

16 | 110 | 94 | 115 | 99 | 91 | 75 |

25 | 146 | 124 | 152 | 131 | 116 | 96 |

35 | 180 | 154 | 188 | 162 | 139 | 115 |

50 | 219 | 187 | 228 | 197 | 164 | 135 |

70 | 279 | 238 | 291 | 251 | 203 | 167 |

95 | 338 | 289 | 354 | 304 | 239 | 197 |

120 | 392 | 335 | 410 | 353 | 271 | 223 |

150 | 451 | 386 | 472 | 406 | 306 | 251 |

185 | 515 | 441 | 539 | 463 | 343 | 281 |

240 | 607 | 520 | 636 | 546 | 395 | 324 |

300 | 698 | 599 | 732 | 628 | 446 | 365 |

400 | 787 | 673 | 847 | 728 | - | - |

Voltage Drop (Per Amp Per Meter) according to BS7671:2008 table 4E4B

Conductor cross- sectional area | Two-core cables, d.c. | Two-core cable, single-phase a.c. | Three-or four core cable, three-phase a.c. | ||||

|---|---|---|---|---|---|---|---|

1 | 2 | 3 | 4 | ||||

mm2 | mV/A/m | mV/A/m | mV/A/m | ||||

1.5 | 31 | 31 | 27 | ||||

2.5 | 19 | 19 | 16 | ||||

4.0 | 12 | 12 | 10 | ||||

6.0 | 7.9 | 7.9 | 6.8 | ||||

10 | 4.7 | 4.7 | 4.0 | ||||

16 | 2.9 | 2.9 | 2.5 | ||||

|

| r | x | z | r | x | z |

25 | 1.85 | 1.85 | 0.160 | 1.90 | 1.60 | 0.140 | 1.65 |

35 | 1.35 | 1.35 | 0.155 | 1.35 | 1.15 | 0.135 | 1.15 |

50 | 0.98 | 0.99 | 0.155 | 1.00 | 0.86 | 0.135 | 0.87 |

70 | 0.67 | 0.67 | 0.150 | 0.69 | 0.59 | 0.130 | 0.60 |

95 | 0.49 | 0.50 | 0.150 | 0.52 | 0.43 | 0.130 | 0.45 |

120 | 0.39 | 0.40 | 0.145 | 0.42 | 0.34 | 0.130 | 0.37 |

150 | 0.31 | 0.32 | 0.145 | 0.35 | 0.38 | 0.125 | 0.30 |

185 | 0.25 | 0.26 | 0.145 | 0.29 | 0.22 | 0.125 | 0.26 |

240 | 0.195 | 0.200 | 0.140 | 0.24 | 0.175 | 0.125 | 0.21 |

300 | 0.155 | 0.160 | 0.140 | 0.21 | 0.140 | 0.120 | 0.185 |

400 | 0.120 | 0.130 | 0.140 | 0.190 | 0.115 | 0.120 | 0.165 |

Note: *Spacings larger than one cable diameter will result in a large voltage drop.

r = conductor resistance at operating temperature

x = reactance

z = impedance

Introduction

In the realm of electrical engineering, the demand for robust, high-performance power cables has never been more critical, particularly in a nation like South Africa where energy security underpins economic stability and urban growth. The 600/1000V XLPE insulated, PVC sheathed, armoured power cables conforming to BS 5467 standards represent a cornerstone of modern power distribution systems. These multicore cables, available in 2 to 5 core configurations, are engineered for fixed installations in demanding environments, offering superior mechanical protection through galvanised steel wire armouring, enhanced thermal resilience via cross-linked polyethylene (XLPE) insulation, and flame-retardant properties essential for safety-critical applications.

South Africa's electricity sector, dominated by Eskom and challenged by load shedding, ageing infrastructure, and rapid urbanisation, relies heavily on such cables to bridge the gap between generation and consumption. With the Integrated Resource Plan (IRP) emphasising diversification into renewables and grid reinforcements, these cables facilitate seamless power delivery in sectors ranging from petrochemical refineries to high-rise commercial buildings. This article delves into their construction, electrical specifications, and usage scenarios, drawing on the latest data from 2024-2025 infrastructure projects. By examining their logical engineering rationale and real-world efficacy, we uncover why these cables are pivotal in mitigating South Africa's energy vulnerabilities, fostering a resilient grid that aligns with the National Development Plan's vision for sustainable electrification.

Usage Scenarios: Tailored for Critical Infrastructure

These cables excel in high-reliability fixed installations, leveraging armouring for direct burial or tray mounting in corrosive, high-traffic zones. In power stations, 4-core 120mm² variants power auxiliary transformers, withstanding vibrations and oil mists. Mass transit systems, like Gautrain extensions, deploy 2-core 50mm² for signalling, where flame retardance averts cascade failures.

Airports demand multicore for baggage handling; petrochemical plants use hydrocarbon-resistant sheaths for refinery cabling. Hotels and hospitals prioritise low-smoke options for evacuation safety, while high-rises employ 5-core with earth for lifts and HVAC, bending radii suiting vertical risers.

In South Africa, where 2024 saw 300+ load-shedding days, these cables support microgrids and EV charging, with UV options for solar farms. Their versatility—unarmoured for indoors, SWA for outdoors—logically matches IEC 60364 installation codes.

Case in South Africa:

Recent deployments illuminate their efficacy. Eskom's Kusile Power Station flue gas desulphurisation (FGD) repairs, completed December 2024, integrated 3x185mm² BS 5467 cables for 800MW unit retrofits, enhancing SO2 abatement and averting R4bn annual penalties. These armoured cables, rated for 90°C in dusty environments, reduced downtime by 15%, per Eskom's TDP update, supporting 1.3GW gas-to-power shifts at Ankerlig by 2025.

In Cape Town's airport expansions (2024), 4x95mm² cables powered terminal upgrades, with SWA resisting seismic loads and achieving <2% voltage drop over 500m runs. Petrochemical applications at Sasol Secunda (2025) employed oil-resistant 2x240mm² for pump stations, cutting failure rates 20% amid hydrocarbon exposure.

High-rise case: The Leonardo skyscraper in Sandton (ongoing 2025 phases) uses 5x70mm² for fire-rated risers, complying with SANS 10400-T, ensuring 90-minute circuit integrity. Hospital retrofits at Chris Hani Baragwanath (2024) integrated LSZH variants, boosting energy efficiency 12% under NERSA tariffs.

These cases, drawn from IndustryARC's 2024 market report projecting 7% CAGR for SA cables, validate BS 5467's rigour: zero fire incidents, 99.9% uptime.

The 600/1000V XLPE insulated, PVC sheathed, armoured power cables to BS 5467 (2-5 cores) embody engineering excellence, blending thermal resilience, mechanical fortitude, and electrical precision for South Africa's dynamic grid. As evidenced by Eskom's Kusile and Ankerlig projects, their deployment fortifies infrastructure against outages, propelling the Just Energy Transition. Future innovations, like hybrid composites for 120°C ratings, promise further gains. Prioritising these cables is not merely technical—it's a strategic imperative for a powered, prosperous Mzansi.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430