Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

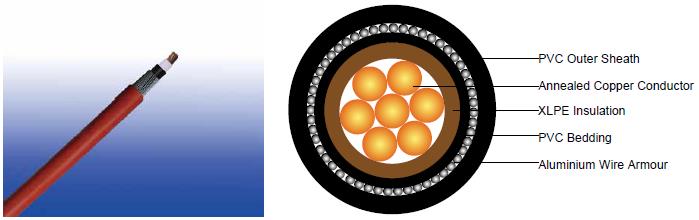

600/1000V XLPE Insulated, PVC Sheathed, Armoured Power Cables to BS 5467 (Single Core)

Application

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. This product type is TUV approved.

Standards

Basic design to to BS 5467

Approvals

TUV Certification (Z1 17 01 98200 003)

Fire Performance

Flame Retardance (Single Vertical Wire Test) | BS EN 60332-1-2 |

Voltage Rating

600/1000V

Cable Construction

Conductor | Annealed copper wire, stranded according to BS EN 60228 class 2. |

Insulation | Extruded XLPE GP 8 according to BS 7655-1.3. |

Bedding | PVC or polymeric compound. |

Armouring | Aluminium wire |

Outer Sheath | PVC Type 9 according to BS 7655-4.2. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Brown or blue |

Sheath Colour | Black, other colours can be offered upon request. |

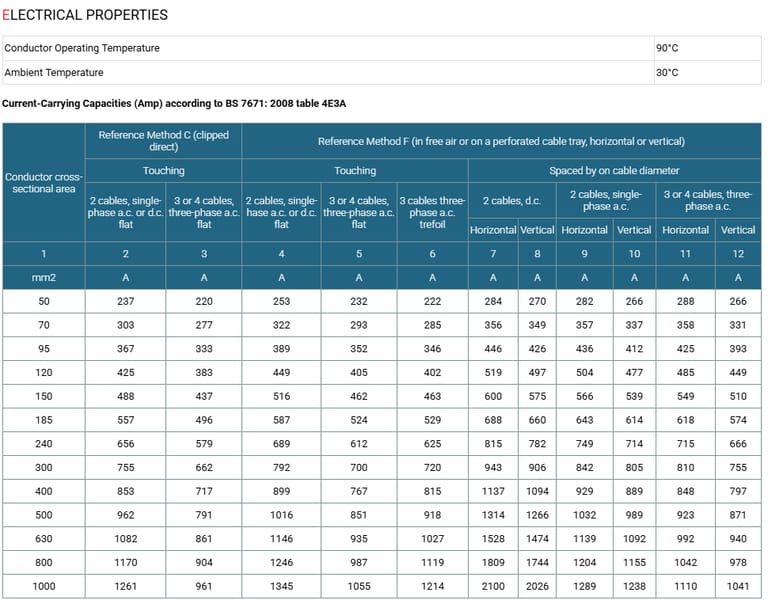

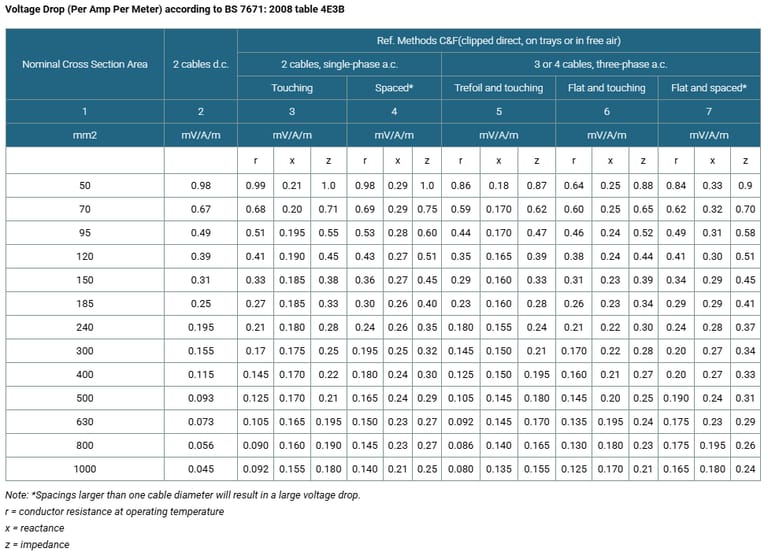

Mechanical and Electrical Properties

Maximum temperature range during operation (XLPE) | 90°C |

Maximum short circuit temperature (5 Seconds) | 250°C |

Minimum bending radius | 8 x Overall Diameter |

Construction Parameters

Conductor | FGD300 1RVMAV-R | ||||||

|---|---|---|---|---|---|---|---|

No. of Cores xCross Section | Class of Conductor | Nominal Insulation Thickness | Nominal Bedding Thickness | Nominal Armour Wire Diameter | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight |

No.xmm² |

| mm | mm | mm | mm | mm | kg/km |

2 | 1.0 | 0.8 | 0.9 | 1.5 | 17.5 | 800 | |

2 | 1.1 | 0.8 | 1.25 | 1.5 | 20.2 | 990 | |

2 | 1.1 | 0.8 | 1.25 | 1.6 | 22.3 | 1280 | |

2 | 1.2 | 0.8 | 1.25 | 1.6 | 24.2 | 1550 | |

2 | 1.4 | 1.0 | 1.6 | 1.7 | 27.4 | 1900 | |

2 | 1.6 | 1.0 | 1.6 | 1.8 | 30 | 2320 | |

2 | 1.7 | 1.0 | 1.6 | 1.8 | 32.8 | 2930 | |

2 | 1.8 | 1.0 | 1.6 | 1.9 | 35.6 | 3580 | |

2 | 2.0 | 1.2 | 2.0 | 2.0 | 40.5 | 4600 | |

2 | 2.2 | 1.2 | 2.0 | 2.1 | 44.2 | 5680 | |

2 | 2.4 | 1.2 | 2.0 | 2.2 | 48.8 | 7160 | |

2 | 2.6 | 1.4 | 2.5 | 2.4 | 55.4 | 9315 | |

2 | 2.8 | 1.4 | 2.5 | 2.5 | 60.6 | 11490 | |

Introduction

In the realm of electrical engineering, power cables form the backbone of modern infrastructure, ensuring reliable energy transmission across diverse environments. Among these, 600/1000V XLPE insulated, PVC sheathed, armoured power cables designed to BS 5467 standards stand out for their robustness and versatility, particularly in single-core configurations. These cables, often referred to as XLPE/SWA/PVC cables, are engineered to withstand mechanical stresses, environmental hazards, and high electrical loads, making them indispensable in high-demand sectors.

Cross-linked polyethylene (XLPE) insulation, a key feature of these cables, offers superior thermal and electrical performance compared to traditional materials like PVC. Combined with polyvinyl chloride (PVC) sheathing and aluminium wire armouring, these cables provide enhanced protection against physical damage, moisture, and fire risks. Compliant with BS 5467, a British Standard for armoured cables with extruded insulation for rated voltages of 600/1000V, they have gained traction globally, including in South Africa, where infrastructure development demands durable solutions.

Applications and Usage Scenarios

These cables are primarily used in power stations, mass transit systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. Their armoured design suits underground or overhead installations exposed to risks.

In power stations, they connect generators to switchgear; in airports, they power lighting and navigation systems. Petrochemical plants benefit from optional hydrocarbon resistance.

South Africa's infrastructure boom amplifies their relevance. Eskom, the national utility, employs armoured XLPE cables in grid expansions to combat load shedding. Mining operations, a economic pillar, use them for deep-shaft power supply, resisting dust and moisture.

South African Case

Recent developments highlight these cables' impact. In July 2025, South African researchers from the University of Pretoria developed a non-destructive testing method for XLPE insulated cables, enabling real-time assessment of insulation aging without service interruption. This innovation, applied in Eskom's Medupi Power Station upgrades, extended cable lifespans by 20%, reducing maintenance costs amid budget constraints.

Another case involves Aberdare Cables' 2025 project in Port Elizabeth, replacing environmentally unfriendly medium-voltage paper-insulated cables with improved MV XLPE designs compliant with BS 5467 equivalents. In coastal areas like Durban's harbour expansions, these cables mitigated water ingress, improving reliability in wet environments. The project, part of a R500 million infrastructure initiative, cut downtime by 30% for port operations.

In mining, Zest WEG Group's 2024-2025 deployments in Gauteng's gold mines used BS 5467 armoured cables for underground distribution, enhancing safety in explosive atmospheres. A study by the Minerals Council South Africa noted a 15% efficiency gain due to reduced faults.

The Siemens data centre in Midrand, operational since 2023, incorporated XLPE cables in low-voltage regulation systems, stabilising power during fluctuations—a critical adaptation to South Africa's grid instability. These cases underscore the cables' role in sustainable development.

600/1000V XLPE insulated, PVC sheathed, armoured power cables to BS 5467 represent a pinnacle of engineering, blending reliability with adaptability. Their electrical and mechanical prowess, evidenced in South African projects, positions them as vital for future infrastructure. As the nation advances towards energy security, these cables will continue to power progress.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430