Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V XLPE Insulated, PVC Sheathed, Armoured Power Cables to IEC 60502 (2-5 Cores & Multicore)

Application

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. This product type is TUV approved.

Standards

Basic design adapted to IEC 60502-1

Approvals

TUV Certification (Z1 17 01 98200 004)

Fire Performance

Flame Retardance (Single Vertical Wire Test) | IEC 60332-1 |

Voltage Rating

600/1000V

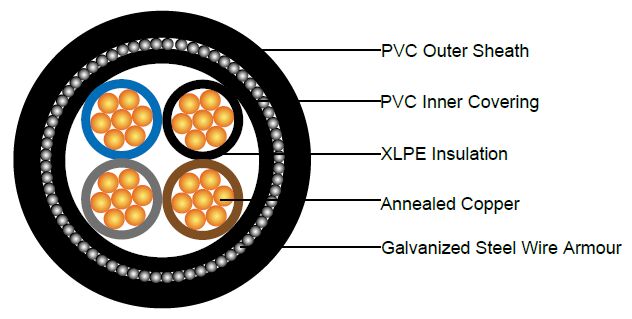

Cable Construction

Conductor | Annealed copper wire, stranded according to IEC 60228 class 2. |

Insulation | XLPE according to IEC 60502-1. |

Inner Covering | Extruded PVC or polymeric compound. |

Armouring | Galvanized steel wire |

Outer Sheath | Extruded PVC Type ST1/ST2 according to IEC 60502-1. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Two-core: Brown, blue |

Sheath Colour | Black, other colours can be offered upon request. |

Physical AND THERMAL PROPERTIES

Maximum temperature range during operation | 80°C (For ST1 Sheath); 90°C (For ST2 Sheath) |

Maximum short circuit temperature (5 Seconds) | 250°C |

Minimum bending radius | 12 x Overall Diameter |

ELECTRICAL PROPERTIES

Conductor Operating Temperature | 90°C |

Ambient Temperature | 30°C |

Current-Carrying Capacities (Amp) according to BS7671:2008 table 4E4A

Conductor crosssectional | Reference Method C (clipped direct) | Reference Method E (in free air | Reference Method D (direct in in | |||

|---|---|---|---|---|---|---|

1 two-core cable*, | 1 three-or four | 1 two-core | 1 three-or four | 1 two-core cable*, | 1 three-or four | |

1 | 2 | 3 | 4 | 5 | 6 | 7 |

mm2 | A | A | A | A | A | A |

1.5 | 27 | 23 | 29 | 25 | 25 | 21 |

2.5 | 36 | 31 | 39 | 33 | 33 | 28 |

4.0 | 49 | 42 | 52 | 44 | 43 | 36 |

6.0 | 62 | 53 | 66 | 56 | 53 | 44 |

10 | 85 | 73 | 90 | 78 | 71 | 58 |

16 | 110 | 94 | 115 | 99 | 91 | 75 |

25 | 146 | 124 | 152 | 131 | 116 | 96 |

35 | 180 | 154 | 188 | 162 | 139 | 115 |

50 | 219 | 187 | 228 | 197 | 164 | 135 |

70 | 279 | 238 | 291 | 251 | 203 | 167 |

95 | 338 | 289 | 354 | 304 | 239 | 197 |

120 | 392 | 335 | 410 | 353 | 271 | 223 |

150 | 451 | 386 | 472 | 406 | 306 | 251 |

185 | 515 | 441 | 539 | 463 | 343 | 281 |

240 | 607 | 520 | 636 | 546 | 395 | 324 |

300 | 698 | 599 | 732 | 628 | 446 | 365 |

400 | 787 | 673 | 847 | 728 | - | - |

Voltage Drop (Per Amp Per Meter) according to BS 7671: 2008 table 4E4B

Conductor cross- sectional area | Two-core cables, d.c. | Two-core cable, single-phase a.c. | Three-or four core cable, three-phase a.c. | ||||

|---|---|---|---|---|---|---|---|

1 | 2 | 3 | 4 | ||||

mm2 | mV/A/m | mV/A/m | mV/A/m | ||||

1.5 | 31 | 31 | 27 | ||||

2.5 | 19 | 19 | 16 | ||||

4.0 | 12 | 12 | 10 | ||||

6.0 | 7.9 | 7.9 | 6.8 | ||||

10 | 4.7 | 4.7 | 4.0 | ||||

16 | 2.9 | 2.9 | 2.5 | ||||

|

| r | x | z | r | x | z |

25 | 1.85 | 1.85 | 0.160 | 1.90 | 1.60 | 0.140 | 1.65 |

35 | 1.35 | 1.35 | 0.155 | 1.35 | 1.15 | 0.135 | 1.15 |

50 | 0.98 | 0.99 | 0.155 | 1.00 | 0.86 | 0.135 | 0.87 |

70 | 0.67 | 0.67 | 0.150 | 0.69 | 0.59 | 0.130 | 0.60 |

95 | 0.49 | 0.50 | 0.150 | 0.52 | 0.43 | 0.130 | 0.45 |

120 | 0.39 | 0.40 | 0.145 | 0.42 | 0.34 | 0.130 | 0.37 |

150 | 0.31 | 0.32 | 0.145 | 0.35 | 0.38 | 0.125 | 0.30 |

185 | 0.25 | 0.26 | 0.145 | 0.29 | 0.22 | 0.125 | 0.26 |

240 | 0.195 | 0.200 | 0.140 | 0.24 | 0.175 | 0.125 | 0.21 |

300 | 0.155 | 0.160 | 0.140 | 0.21 | 0.140 | 0.120 | 0.185 |

400 | 0.120 | 0.130 | 0.140 | 0.190 | 0.115 | 0.120 | 0.165 |

Note: *Spacings larger than one cable diameter will result in a large voltage drop.

r = conductor resistance at operating temperature

x = reactance

z = impedance

Introduction

In the heart of South Africa's bustling cities and expansive industrial landscapes, reliable electricity distribution is the lifeblood of progress. Enter the 600/1000V XLPE Insulated, PVC Sheathed, Armoured Power Cables, designed to IEC 60502-1 standards for 2-5 cores and multicore configurations. These cables represent a cornerstone of modern electrical engineering, offering robust protection and efficient power transmission in demanding environments. XLPE, or cross-linked polyethylene, serves as the insulation material, providing superior thermal and electrical properties compared to traditional alternatives. Approved by TUV and adapted to international standards, these cables are engineered for safety and longevity, making them ideal for South Africa's diverse infrastructure needs—from powering Johannesburg's skyscrapers to supporting Cape Town's mass transit systems.

Application Scenarios

These XLPE insulated armoured cables shine in high-stakes environments where reliability is non-negotiable. Primarily used in power stations, they facilitate stable energy distribution amid South Africa's ongoing efforts to expand renewable sources like solar and wind farms in the Northern Cape. In mass transit systems, such as Gauteng's Gautrain or Durban's public transport networks, they power underground passenger systems, ensuring uninterrupted service in confined spaces.

Airports like OR Tambo International in Johannesburg rely on them for critical operations, from runway lighting to terminal power supplies. Petrochemical plants in Secunda, hospitals across the provinces, and high-rise buildings in Sandton benefit from their armoured design, which protects against mechanical damage and environmental hazards. With options for enhanced fire performance compliant with IEC 60332-1, they're suited for densely populated areas, reducing risks in emergencies. In rural and mining areas, their resistance to rodents and termites proves invaluable, adapting to South Africa's varied terrains.

Advantages

The advantages of these cables extend beyond basic functionality, offering a blend of safety, efficiency, and cost-effectiveness tailored to South African conditions. XLPE insulation provides excellent thermal stability, allowing operation at higher temperatures without degradation, which translates to longer service life—potentially decades in moderate climates. The galvanised steel armour adds mechanical protection against impacts, crushing, and abrasion, crucial in construction sites or underground installations prone to earth movements.

Fire retardance is a standout feature, meeting IEC 60332-1 for single vertical wire tests, minimising flame spread in buildings. Customisable sheath options combat local challenges like UV exposure in arid regions or hydrocarbon resistance in oil-rich areas. Compared to older paper-insulated lead-covered (PILC) cables, XLPE variants are lighter, easier to install, and more environmentally friendly, with lower maintenance needs. In economic terms, their high current-carrying capacity reduces energy losses, supporting South Africa's push for sustainable power under the Integrated Resource Plan.

South African Case Studies

South Africa's adoption of XLPE insulated armoured cables has been marked by innovative projects and research, highlighting their practical impact. In the mining sector of Gauteng, a 2025 project deployed thick steel wire armoured cables to power underground operations. These cables withstood crushing forces and deterred pests, enhancing safety and reducing downtime in one of the country's key economic drivers.

Another example comes from urban network upgrades, where municipalities have migrated from outdated PILC to XLPE cables for medium-voltage electricity distribution. This shift, investigated in depth by the University of KwaZulu-Natal, improved reliability in cities like Durban, cutting failure rates and supporting load-shedding mitigation efforts.

Research at the University of Pretoria explored buried medium-voltage XLPE cables with steel wire armouring and water-blocking tape, proposing diagnostic methods for South African conditions. Additionally, a 2025 study by South African scientists developed non-destructive testing for XLPE cables, enabling predictive maintenance in high-voltage projects now dominated by single-core XLPE designs. These cases underscore the cables' role in advancing local infrastructure resilience.

Frequently Asked Questions (FAQs)

What is the difference between XLPE and PVC insulation?

XLPE offers better heat resistance and electrical properties, making it suitable for higher temperatures, while PVC is more flexible but less durable in extreme conditions.

Are these cables suitable for outdoor use in South Africa?

Yes, with UV-resistant sheath options, they're ideal for exposed installations in sunny regions like the Karoo.

How do I select the right core configuration?

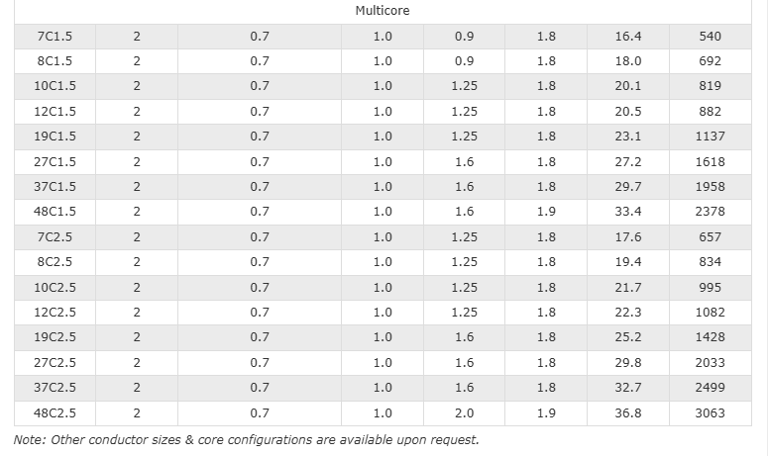

For single-phase applications, opt for two-core; three- or four-core for three-phase. Multicore (up to 48 cores) suits control systems—consult specs for your load requirements.

What maintenance is required?

Minimal; regular visual inspections for damage suffice, thanks to the armoured design. Use non-destructive testing methods for longevity.

Can these cables handle South Africa's variable weather?

Absolutely—their thermal range and optional protections ensure performance from coastal humidity to inland heat.

Conclusion

As South Africa strides towards a more electrified and sustainable future, 600/1000V XLPE Insulated, PVC Sheathed, Armoured Power Cables to IEC 60502 stand as reliable allies. Their blend of advanced specs, versatile applications, and proven advantages positions them at the forefront of infrastructure development. Whether in mining depths or urban heights, these cables power progress with safety and efficiency. For engineers and decision-makers, embracing this technology means investing in a brighter, more connected tomorrow.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430