Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V XLPE Insulated, PVC Sheathed, Armoured Power Cables to IEC 60502 (Single Core)

Application

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings.This product type is TUV approved.

Standards

Basic design to to IEC 60502-1

Approvals

TUV Certification (Z1 17 01 98200 004)

Fire Performance

Flame Retardance (Single Vertical Wire Test) | IEC 60332-1 |

Voltage Rating

600/1000V

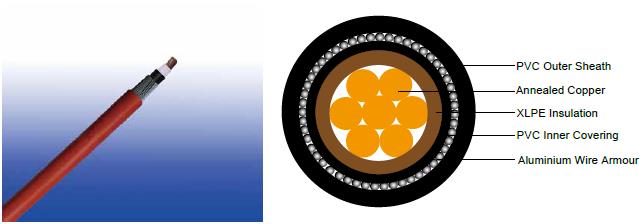

Cable Construction

Conductor | Annealed copper wire, stranded according to IEC 60228 class 2. |

Insulation | XLPE according to IEC 60502-1. |

Inner Covering | Extruded PVC or polymeric compound. |

Armouring | Aluminium wire |

Outer Sheath | Extruded PVC Type ST1/ST2 according to IEC 60502-1. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Brown or blue, other colours can be offered upon request. |

Sheath Colour | Black, other colours can be offered upon request. |

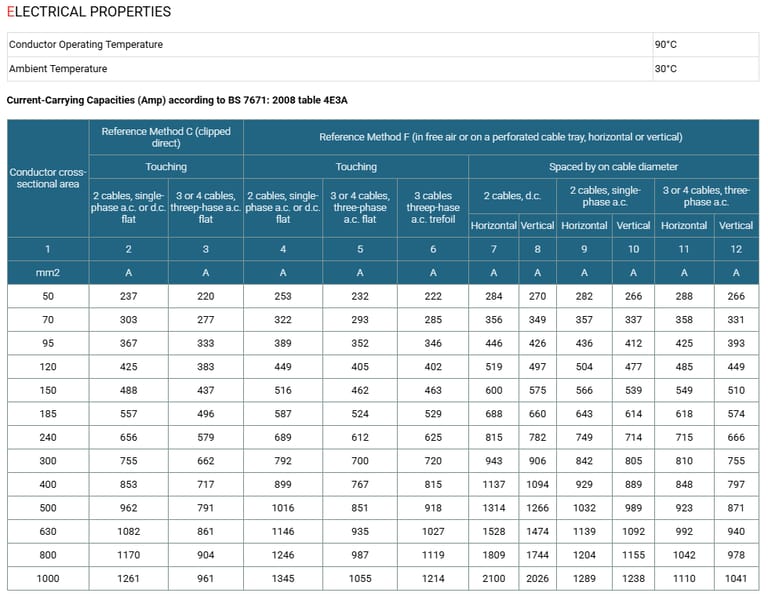

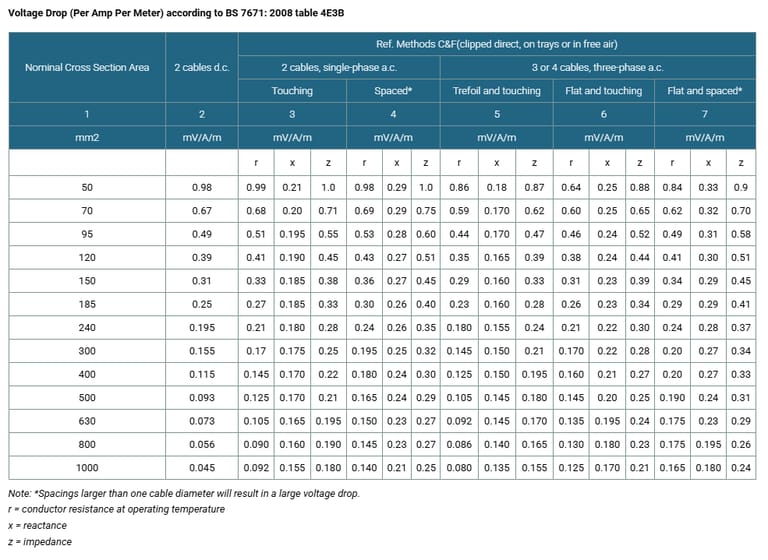

Mechanical and Electrical Properties

Maximum temperature range during operation | 80°C (For ST1 Sheath); 90°C (For ST2 Sheath) |

Maximum short circuit temperature (5 Seconds) | 250°C |

Minimum bending radius | |

Circular copper conductors | 6 x Overall Diameter |

Shaped copper conductors | 8 x Overall Diameter |

Construction Parameters

Conductor | FGD300 1RVMAV-R | ||||||

|---|---|---|---|---|---|---|---|

No. of Cores × Cross Section | Class of Conductor | Nominal Insulation Thickness | Nominal Inner Covering Thickness | Nominal Armour Wire Diameter | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight |

No.xmm² |

| mm | mm | mm | mm | mm | kg/km |

2 | 0.7 | 1.0 | 0.8 | 1.8 | 10.2 | 150 | |

2 | 0.7 | 1.0 | 0.8 | 1.8 | 10.6 | 169 | |

2 | 0.7 | 1.0 | 0.8 | 1.8 | 11.2 | 196 | |

2 | 0.7 | 1.0 | 0.8 | 1.8 | 11.7 | 228 | |

2 | 0.7 | 1.0 | 0.8 | 1.8 | 12.7 | 290 | |

2 | 0.7 | 1.0 | 0.8 | 1.8 | 13.7 | 372 | |

2 | 0.9 | 1.0 | 0.8 | 1.8 | 15.4 | 507 | |

2 | 0.9 | 1.0 | 1.25 | 1.8 | 17.5 | 681 | |

2 | 1.0 | 1.0 | 1.25 | 1.8 | 19.0 | 848 | |

2 | 1.1 | 1.0 | 1.25 | 1.8 | 21.0 | 1116 | |

2 | 1.1 | 1.0 | 1.6 | 1.8 | 24.0 | 1511 | |

2 | 1.2 | 1.0 | 1.6 | 1.8 | 25.8 | 1821 | |

2 | 1.4 | 1.0 | 1.6 | 1.8 | 27.8 | 2165 | |

2 | 1.6 | 1.0 | 1.6 | 1.8 | 30.4 | 2655 | |

2 | 1.7 | 1.0 | 1.6 | 1.9 | 33.5 | 3352 | |

2 | 1.8 | 1.0 | 2.0 | 2.0 | 37.5 | 4224 | |

2 | 2.0 | 1.2 | 2.0 | 2.2 | 41.3 | 5263 | |

2 | 2.2 | 1.2 | 2.0 | 2.3 | 44.2 | 7379 | |

2 | 2.4 | 1.2 | 2.5 | 2.4 | 49.8 | 9611 | |

2 | 2.6 | 1.4 | 2.5 | 2.6 | 55.3 | 11896 | |

2 | 2.8 | 1.4 | 2.5 | 2.7 | 60.4 | 14467 | |

Introduction

In modern electrical infrastructure, the choice of power cables significantly impacts safety, efficiency, and reliability. Among the various options available, 600/1000V XLPE insulated, PVC sheathed, armoured power cables, designed to meet IEC 60502-1 standards, are widely used in demanding environments such as power stations, mass transit systems, and high-rise buildings. These cables, approved by TÜV and compliant with stringent fire performance standards, are particularly relevant in South Africa, where rapid urbanisation and industrial growth necessitate robust electrical solutions.

Fire Performance

These cables are designed to meet flame retardance standards under IEC 60332-1 (Single Vertical Wire Test). Additional compliance with standards like IEC 60332-3, UL 1581, or UL 1666 can be achieved by adjusting the oxygen index of the PVC compound. Low-smoke PVC (LSPVC) options are available for enhanced safety in enclosed spaces, a critical consideration in South African public infrastructure projects.

Applications in South Africa

Urban Infrastructure

South Africa’s rapid urbanisation, particularly in cities like Johannesburg, Cape Town, and Durban, has increased the demand for reliable power distribution systems. These XLPE insulated cables are ideal for high-rise buildings, hospitals, and hotels due to their fire-retardant properties and mechanical robustness. For instance, in the construction of the Iconic Tower in Sandton, Johannesburg (completed in 2023), these cables were used to ensure safe and efficient power distribution across the 28-story mixed-use building. Their UV-resistant and flame-retardant sheaths were critical in meeting South Africa’s stringent building codes.

Mass Transit Systems

The Gautrain, South Africa’s high-speed rail network, relies on these cables for its underground power distribution systems. A 2024 upgrade to the Gautrain’s Sandton station incorporated 600/1000V XLPE cables with LSPVC sheaths to enhance safety in confined spaces. The cables’ aluminium armouring provided protection against mechanical damage in the challenging underground environment.

Industrial and Petrochemical Plants

In South Africa’s petrochemical sector, such as Sasol’s Secunda plant, these cables are used for their hydrocarbon and oil-resistant properties. A 2025 retrofit project at Secunda replaced older cables with these XLPE insulated variants to improve reliability and safety in a high-risk environment. The cables’ ability to withstand temperatures up to 90°C and resist chemical degradation was a key factor in their selection.

Renewable Energy Projects

South Africa’s push towards renewable energy, exemplified by projects like the Kathu Solar Park (completed in 2019 but expanded in 2024), has increased the use of these cables in solar and wind farms. Their UV-resistant sheaths and high current-carrying capacities make them suitable for connecting inverters and transformers in harsh outdoor conditions.

Advantages and Limitations

Advantages

High Thermal Stability: The XLPE insulation’s 90°C operating temperature and 250°C short-circuit tolerance make these cables suitable for demanding environments.

Fire Safety: Compliance with IEC 60332-1 and optional LSPVC sheaths enhance safety in public spaces.

Versatility: Customizable sheath properties (e.g., UV or oil resistance) cater to diverse applications, from petrochemical plants to renewable energy installations.

Durability: Aluminium armouring protects against mechanical damage, extending cable lifespan in harsh conditions.

Limitations

Weight and Cost: Larger conductor sizes (e.g., 1000 mm²) are heavy (14,467 kg/km) and costly, posing challenges for installation and budgeting.

Bending Radius: The minimum bending radius (6–8 times the diameter) may limit flexibility in confined spaces.

Environmental Impact: PVC sheaths, while effective, are less environmentally friendly than alternatives like polyethylene, especially in non-LSPVC variants.

The 600/1000V XLPE insulated, PVC sheathed, armoured power cables to IEC 60502-1 are a cornerstone of South Africa’s electrical infrastructure, offering a balance of safety, durability, and performance. Their robust construction, high current-carrying capacity, and compliance with fire safety standards make them ideal for applications ranging from urban high-rises to industrial plants and renewable energy projects. Recent case studies, such as the Menlyn Maine Central Square and Cape Town International Airport expansion, underscore their reliability in real-world scenarios. While challenges like cost and environmental impact remain, ongoing innovations in cable materials and smart grid integration promise to enhance their utility in South Africa’s evolving energy landscape.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430