Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V XLPE Insulated, PVC Sheathed, Unarmoured Power Cables to BS 7889 (2-5 Cores)

Application

The cables are mainly use in fixed installations in industrial areas, buildings and similar applications but not for burial in the ground, either directly or in ducts.

Standards

Basic design to to BS 7889:2012

Approvals

TUV Certification (Z1 17 08 98200 008)

Fire Performance

Flame Retardance (Single Vertical Wire Test) | BS EN 60332-1-2 |

Voltage Rating

600/1000V

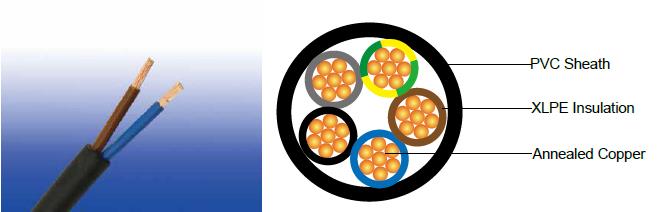

Cable Construction

Conductor | Annealed copper wire, stranded according to BS EN 60228 class 2. |

Insulation | XLPE type GP8 according to BS 7655-1.3. |

Filling | If necessary, the formation of a compact and reasonably circular cable shall be achieved by one of the following methods. |

Inner Covering Option | The optional inner covering, where used, shall consist of an extruded layer of synthetic polymeric material. It shall surround the single core and the laid-up two, three, four or five cores, giving the assembly a practically circular shape. |

Outer Sheath | PVC Type 9 according to BS 7655-4.2. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Two-core: Brown, blue |

Sheath Colour | Black, other colours can be offered upon request |

Physical AND THERMAL PROPERTIES

Maximum temperature range during operation (XLPE) | 90°C | |||||||||

Maximum short circuit temperature (5 Seconds) | 250°C | |||||||||

| ||||||||||

Minimum bending radius |

| |||||||||

| ||||||||||

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E2A

| Reference Method A | Reference Method B | Reference Method C | Reference Method E | ||||

1 two-core | 1 three- or | 1 two-core | 1 three- or | 1 two-core | 1 three- or | 1 two-core | 1 three- or | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm2 | A | A | A | A | A | A | A | A |

1.5 | 18.5 | 16.5 | 22 | 19.5 | 24 | 22 | 26 | 23 |

2.5 | 25 | 22 | 30 | 26 | 33 | 30 | 36 | 32 |

4.0 | 33 | 30 | 40 | 35 | 45 | 40 | 49 | 42 |

6.0 | 42 | 38 | 51 | 44 | 58 | 52 | 63 | 54 |

10 | 57 | 51 | 69 | 60 | 80 | 71 | 86 | 75 |

16 | 76 | 68 | 91 | 80 | 107 | 96 | 115 | 100 |

25 | 99 | 89 | 119 | 105 | 138 | 119 | 149 | 127 |

35 | 121 | 109 | 146 | 128 | 171 | 147 | 185 | 158 |

50 | 145 | 130 | 175 | 154 | 209 | 179 | 225 | 192 |

70 | 183 | 164 | 221 | 194 | 269 | 229 | 289 | 246 |

95 | 220 | 197 | 265 | 233 | 328 | 278 | 352 | 298 |

120 | 253 | 227 | 305 | 268 | 382 | 322 | 410 | 346 |

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E2B

| Two-core cable d.c. | Two-core cable, single-phase a.c. | Three- or four-core cable, three-phase a.c. | ||||

1 | 2 | 3 | 4 | ||||

mm2 | mV/A/m | mV/A/m | mV/A/m | ||||

1.5 | 31 | 31 | 27 | ||||

2.5 | 19 | 19 | 16 | ||||

4.0 | 12 | 12 | 10 | ||||

6.0 | 7.9 | 7.9 | 6.8 | ||||

10 | 4.7 | 4.7 | 4.0 | ||||

16 | 2.9 | 2.9 | 2.5 | ||||

|

| r | x | z | r | x | z |

25 | 1.85 | 1.85 | 0.160 | 1.90 | 1.60 | 0.140 | 1.65 |

35 | 1.35 | 1.35 | 0.155 | 1.35 | 1.15 | 0.135 | 1.15 |

50 | 0.98 | 0.99 | 0.155 | 1.00 | 0.86 | 0.135 | 0.87 |

70 | 0.67 | 0.67 | 0.150 | 0.69 | 0.59 | 0.130 | 0.60 |

95 | 0.49 | 0.50 | 0.150 | 0.52 | 0.43 | 0.130 | 0.45 |

120 | 0.39 | 0.40 | 0.145 | 0.42 | 0.34 | 0.130 | 0.37 |

Note: *Spacings larger than one cable diameter will result in a large voltage drop.

r = conductor resistance at operating temperature

x = reactance

z = impedance

Introduction

In the realm of electrical engineering, the choice of power cables is critical to ensuring safety, efficiency, and reliability in various applications. The 600/1000V XLPE insulated, PVC sheathed, unarmoured power cables, designed to the British Standard BS 7889:2012, are widely used in fixed installations across industrial and building environments. These cables, available in configurations of two to five cores, are engineered for optimal performance under specific electrical and environmental conditions.

Fire Performance

Fire safety is paramount in cable design, especially in densely populated or industrial environments. These cables comply with BS EN 60332-1-2 for flame retardance, ensuring they resist flame propagation in a single vertical wire test. Optional compliance with standards like IEC 60332-3, UL 1581, or UL 1666 can be achieved by adjusting the PVC compound’s oxygen index. Low-smoke PVC (LSPVC) variants are available for applications requiring reduced smoke emission, a critical consideration in South African public buildings and industrial facilities.

Applications in South Africa

The 600/1000V XLPE insulated, PVC sheathed, unarmoured power cables are ideal for fixed installations in industrial areas, commercial buildings, and residential complexes. Their unarmoured design makes them unsuitable for direct burial but perfect for indoor or protected outdoor installations. In South Africa, these cables are extensively used due to their reliability and compliance with international standards like BS 7889:2012 and TUV certification (Z1 17 08 98200 008).

Case Study 1: Industrial Application in Gauteng

In 2023, a manufacturing plant in Johannesburg’s industrial hub upgraded its electrical infrastructure using 600/1000V XLPE insulated, four-core 50 mm² cables. The plant required reliable power distribution for heavy machinery operating in a high-temperature environment. The cables’ XLPE insulation ensured continuous operation at 90°C, while the PVC sheath provided resistance to oil and UV exposure, common in Gauteng’s industrial zones. The installation, adhering to Reference Method C (clipped direct), achieved a current-carrying capacity of 209 A, meeting the plant’s power demands efficiently. This project highlighted the cables’ suitability for demanding industrial applications, reducing downtime and maintenance costs.

Case Study 2: Commercial Building in Cape Town

A 2024 retrofit of a commercial office building in Cape Town’s CBD utilized three-core 25 mm² cables for lighting and HVAC systems. The cables were installed in trunking (Reference Method B), delivering a current-carrying capacity of 105 A for three-phase AC. The project incorporated LSPVC sheaths to comply with South African fire safety regulations (SANS 10142-1), minimizing smoke emission risks in a high-occupancy building. The cables’ compact design and flexibility (4 x overall diameter bending radius) facilitated installation in constrained ceiling spaces, demonstrating their adaptability to modern architectural designs.

Case Study 3: Renewable Energy Integration in the Western Cape

In 2025, a solar energy project in the Western Cape integrated these cables into a microgrid system connecting solar inverters to distribution boards. Two-core 16 mm² cables were used for single-phase AC connections, supporting 107 A (Reference Method E). The UV-resistant PVC sheath was critical in the region’s sunny climate, ensuring long-term durability. The project underscored the cables’ role in South Africa’s transition to renewable energy, aligning with the country’s Integrated Resource Plan (IRP) for sustainable energy development

Advantages and Limitations

Advantages

Thermal Resilience: XLPE insulation supports high operating temperatures, ideal for South Africa’s warm climate.

Electrical Efficiency: Low voltage drop and high current-carrying capacity ensure minimal power losses.

Fire Safety: Compliance with flame retardance standards enhances safety in public and industrial settings.

Customizability: Optional sheath properties cater to specific environmental challenges, such as UV or pest resistance.

Limitations

Not Suitable for Direct Burial: The unarmoured design limits use in underground applications without additional protection.

Cost Considerations: Enhanced sheath options (e.g., UV or oil resistance) may increase costs, impacting budget-sensitive projects.

Installation Constraints: Larger conductor sizes require greater bending radii, posing challenges in compact installations.

The 600/1000V XLPE insulated, PVC sheathed, unarmoured power cables to BS 7889:2012 are a cornerstone of modern electrical installations in South Africa. Their robust construction, excellent electrical properties, and compliance with international and local standards make them a reliable choice for industrial, commercial, and renewable energy applications. Recent case studies from Gauteng, Cape Town, and the Western Cape demonstrate their versatility and effectiveness in addressing diverse electrical needs. While limitations such as unsuitability for direct burial and potential cost increases for enhanced features exist, the cables’ benefits far outweigh these challenges. As South Africa continues to develop its infrastructure and energy systems, these cables will play a pivotal role in ensuring safe, efficient, and sustainable power distribution.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430