Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V XLPE Insulated, PVC Sheathed, Unarmoured Power Cables to BS 7889 (Single Core)

600/1000V XLPE Insulated, PVC Sheathed, Unarmored Power Cables to BS 7889: Engineered for Robust Performance in Various Industrial and Building Applications

600/1000V XLPE Insulated, PVC Sheathed, Unarmoured Power Cables to BS 7889 (Single Core)

FGD300 1RV-R (CU/XLPE/PVC 600/1000V Class 2)

BS Code: 6181X

Application

BS 7889 CU/XLPE/PVC are mainly use in fixed installations in industrial areas, buildings and similar applications but not for burial in the ground, either directly or in ducts.

Standards

Basic design to to BS 7889:2012

Fire Performance

Flame Retardance (Single Vertical Wire Test) | BS EN 60332-1-2 |

Voltage Rating

600/1000V

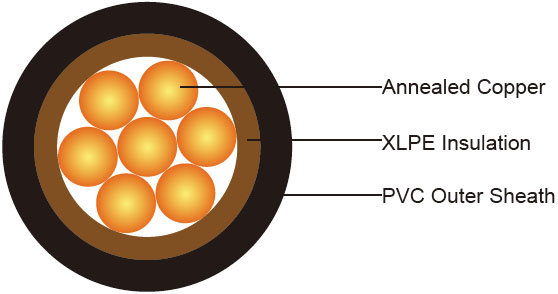

Cable Construction

Conductor | Annealed copper conductor, class 5 according to BS EN 60228. |

Insulation | XLPE type GP8 according to BS 7655-1.3. |

Inner Covering Option | The optional inner covering, where used, shall consist of an extruded layer of synthetic polymeric material. It shall surround the single core and the laid-up two, three, four or five cores, giving the assembly a practically circular shape. |

Outer Sheath | PVC Type 9 according to BS 7655-4.2. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Brown or blue |

Sheath Colour | Black, other colours can be offered upon request. |

Mechanical and Electrical Properties

Maximum temperature range during operation (XLPE) | 90°C |

Maximum short circuit temperature (5 Seconds) | 250°C |

Minimum bending radius | Circular copper conductor (OD≤25mm): 4 x Overall Diameter |

| Circular copper conductor (OD>25mm): 6 x Overall Diameter |

| Shaped copper conductor: 8 x Overall Diameter |

Construction Parameters

Conductor | FGD300 1RV-R | ||||

|---|---|---|---|---|---|

No. of Cores xCross Section | Class of Conductor | Nominal Insulation Thickness | Nominal Sheath Thickness | Nominal Overall Diameter | Approx.Weight |

No.xmm2 |

| mm | mm | mm | kg/km |

1x1.5 | 2 | 0.7 | 1.4 | 6.1 | 36 |

1x2.5 | 2 | 0.7 | 1.4 | 6.8 | 52 |

1x4.0 | 2 | 0.7 | 1.4 | 7.4 | 76 |

1x6.0 | 2 | 0.7 | 1.4 | 8.2 | 100 |

1x10 | 2 | 0.7 | 1.4 | 9.2 | 160 |

1x16 | 2 | 0.7 | 1.4 | 10.7 | 230 |

1x25 | 2 | 0.9 | 1.4 | 12.5 | 340 |

1x35 | 2 | 0.9 | 1.4 | 13.5 | 440 |

1x50 | 2 | 1 | 1.4 | 13.7 | 541 |

1x70 | 2 | 1.1 | 1.4 | 15.8 | 749 |

1x95 | 2 | 1.1 | 1.5 | 17.5 | 1000 |

1x120 | 2 | 1.2 | 1.5 | 19.3 | 1241 |

1x150 | 2 | 1.4 | 1.6 | 21.5 | 1523 |

1x185 | 2 | 1.6 | 1.6 | 24.7 | 1942 |

1x240 | 2 | 1.7 | 1.7 | 27.7 | 2514 |

1x300 | 2 | 1.8 | 1.8 | 30.6 | 3125 |

1x400 | 2 | 2 | 1.9 | 34.2 | 3967 |

1x500 | 2 | 2.2 | 2 | 38 | 5063 |

1x630 | 2 | 2.4 | 2.2 | 42.9 | 6491 |

1x800 | 2 | 2.6 | 2.3 | 46 | 8075 |

1x1000 | 2 | 2.8 | 2.4 | 63 | 9860 |

ELECTRICAL PROPERTIES

Conductor Operating Temperature | 70°C |

Ambient Temperature | 30°C |

In the realm of electrical engineering, the choice of power cables significantly impacts the safety, efficiency, and reliability of electrical systems. The 600/1000V XLPE Insulated, PVC Sheathed, Unarmored Power Cables to BS 7889 (Single Core), such as the FGD300 1RV-R, are engineered for robust performance in various industrial and building applications. These cables, compliant with the British Standard BS 7889:2012, offer a blend of durability, flexibility, and fire safety, making them a preferred choice in fixed installations.

Standards Compliance

Adhering to BS 7889:2012, these cables meet rigorous standards for design and performance. The flame-retardant properties align with BS EN 60332-1-2, ensuring safety in fire-prone environments. Optional compliance with international standards like IEC 60332-3 enhances their versatility for global applications.

Usage Scenarios

These cables are designed for fixed installations in industrial areas, commercial buildings, and residential complexes, but they are not suitable for direct burial or ducted underground applications. Common use cases include:

Industrial Facilities: Powering machinery and equipment in factories, where high current-carrying capacity and thermal stability are crucial.

Commercial Buildings: Supplying electricity to lighting, HVAC systems, and other infrastructure in offices and shopping centers.

Residential Complexes: Supporting electrical distribution in multi-unit housing, ensuring reliable power delivery.

Case Studies in South Africa

Case Study 1: Upgrading Electrical Infrastructure in Johannesburg

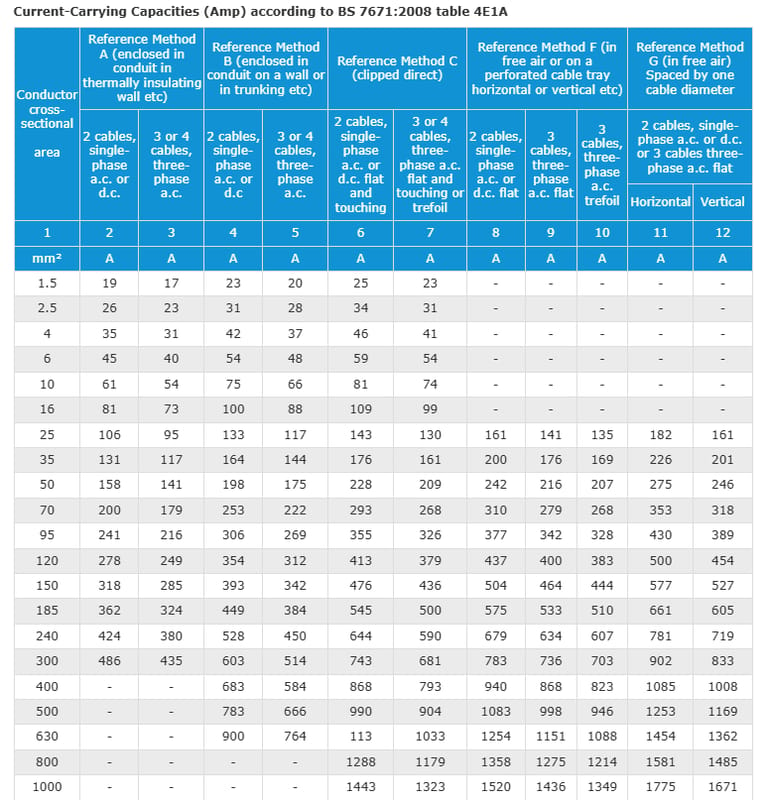

South Africa faces frequent power outages due to aging infrastructure and load-shedding challenges. In 2023, a major commercial complex in Johannesburg underwent a retrofit to improve energy efficiency. The project utilized 600/1000V XLPE Insulated, PVC Sheathed, Unarmored Power Cables for their high current-carrying capacity and flame-retardant properties. The cables, with cross-sections ranging from 50 mm² to 150 mm², were installed in conduit systems (Reference Method B), delivering up to 228 A for single-phase applications. The use of UV-resistant PVC sheathing ensured durability in Johannesburg’s harsh sunlight, reducing maintenance costs. This upgrade reduced downtime and enhanced safety, aligning with South Africa’s push for resilient electrical systems.

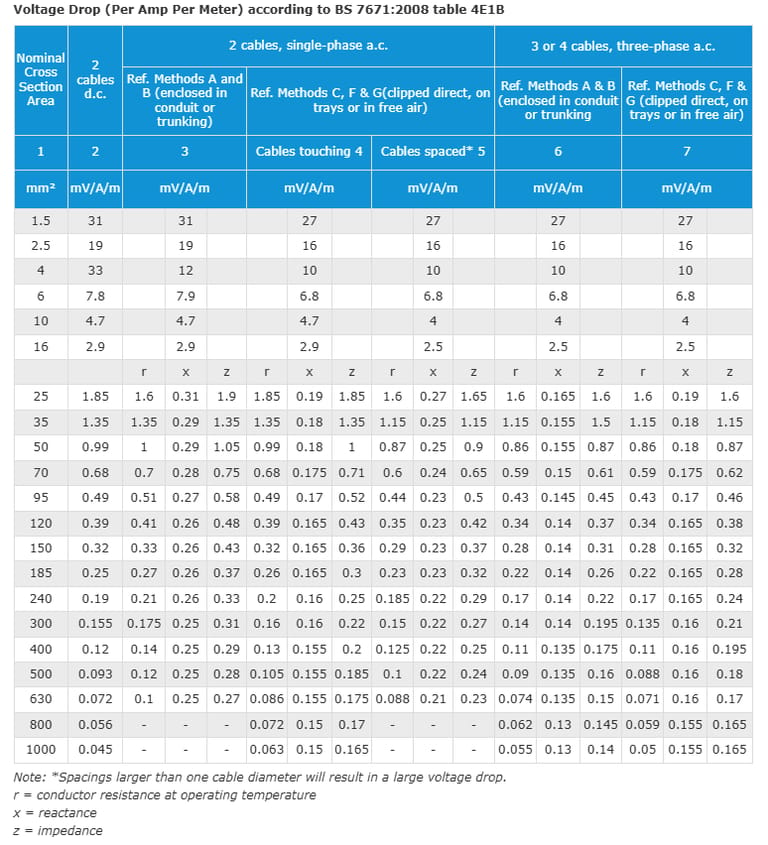

Case Study 2: Renewable Energy Integration in Cape Town

South Africa’s transition to renewable energy has increased demand for reliable power cables in solar and wind installations. In 2024, a solar farm near Cape Town integrated these cables to connect inverters to the main grid. The cables’ XLPE insulation, capable of operating at 90°C, ensured stability under high ambient temperatures. The project used 240 mm² cables, supporting up to 644 A in free air (Reference Method F), with minimal voltage drop (0.24 mV/A/m). The flame-retardant properties complied with IEC 60332-3, critical for safety in remote installations. This case highlights the cables’ role in supporting South Africa’s renewable energy goals.

The 600/1000V XLPE Insulated, PVC Sheathed, Unarmored Power Cables to BS 7889 are a cornerstone of modern electrical systems, offering reliability, safety, and efficiency. Their technical specifications, including high current-carrying capacity, flame retardance, and thermal stability, make them versatile for industrial, commercial, and residential applications. In South Africa, these cables address critical issues like load-shedding, cable theft, and renewable energy integration, as demonstrated in case studies from Johannesburg, Cape Town, and Durban. As the country advances toward sustainable and resilient electrical infrastructure, these cables will continue to play a pivotal role, balancing performance with cost-effectiveness.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430