Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V XLPE Insulated, PVC Sheathed, Unarmoured Power Cables to IEC 60502 (2-5 Cores & Multicore)

Application

The cables are mainly used in power stations, mass transit underground passenger systems, airports, petrochemical plants, hotels, hospitals, and high-rise buildings. This product type is TUV approved.

Standards

Basic design adapted to IEC 60502-1

Approvals

TUV Certification (Z1 17 01 98200 004)

Fire Performance

Flame Retardance (Single Vertical Wire Test) | IEC 60332-1 |

Voltage Rating

600/1000V

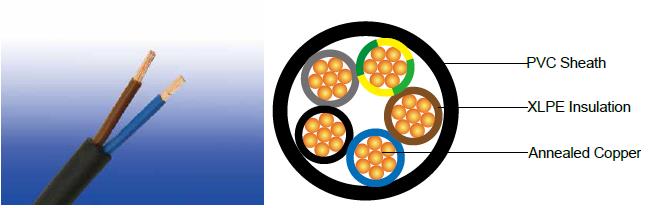

Cable Construction

Conductor | Annealed copper wire, stranded according to BS EN 60228 class 2. |

Insulation | XLPE according to IEC 60502-1. |

Inner Covering Option | Extruded PVC or polymeric compound. |

Outer Sheath | Extruded PVC Type ST1/ST2 according to IEC 60502-1. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3,UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Two-core: Brown, blue |

Sheath Colour | Black, other colours can be offered upon request |

Physical AND THERMAL PROPERTIES

Maximum temperature range during operation | 80°C (For ST1 Sheath); 90°C (For ST2 Sheath) |

Maximum short circuit temperature (5 Seconds) | 250°C |

| |

Minimum bending radius | 12 x Overall Diameter |

ELECTRICAL PROPERTIES

Conductor Operating Temperature | 90°C |

Ambient Temperature | 30°C |

Current-Carrying Capacities (Amp) according to BS 7671:2008 table 4E2A

Conductor cross- sectional area | Reference Method A | Reference Method B | Reference Method C | Reference Method E | ||||

|---|---|---|---|---|---|---|---|---|

1 two-core | 1 three- or | 1 two-core | 1 three- or | 1 two-core | 1 three- or | 1 two-core | 1 three- or | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

mm2 | A | A | A | A | A | A | A | A |

1.5 | 18.5 | 16.5 | 22 | 19.5 | 24 | 22 | 26 | 23 |

2.5 | 25 | 22 | 30 | 26 | 33 | 30 | 36 | 32 |

4.0 | 33 | 30 | 40 | 35 | 45 | 40 | 49 | 42 |

6.0 | 42 | 38 | 51 | 44 | 58 | 52 | 63 | 54 |

10 | 57 | 51 | 69 | 60 | 80 | 71 | 86 | 75 |

16 | 76 | 68 | 91 | 80 | 107 | 96 | 115 | 100 |

25 | 99 | 89 | 119 | 105 | 138 | 119 | 149 | 127 |

35 | 121 | 109 | 146 | 128 | 171 | 147 | 185 | 158 |

50 | 145 | 130 | 175 | 154 | 209 | 179 | 225 | 192 |

70 | 183 | 164 | 221 | 194 | 269 | 229 | 289 | 246 |

95 | 220 | 197 | 265 | 233 | 328 | 278 | 352 | 298 |

120 | 253 | 227 | 305 | 268 | 382 | 322 | 410 | 346 |

150 | 290 | 259 | 334 | 300 | 441 | 371 | 473 | 399 |

185 | 329 | 295 | 384 | 340 | 506 | 424 | 542 | 456 |

240 | 386 | 346 | 459 | 398 | 599 | 500 | 641 | 538 |

300 | 442 | 396 | 532 | 455 | 693 | 576 | 741 | 621 |

400 | - | - | 625 | 536 | 803 | 667 | 865 | 741 |

Voltage Drop (Per Amp Per Meter) according to BS 7671:2008 table 4E2B

Nominal Cross Section Area | Two-core cable d.c. | Two-core cable, single-phase a.c. | Three- or four-core cable, three-phase a.c. | ||||

|---|---|---|---|---|---|---|---|

1 | 2 | 3 | 4 | ||||

mm2 | mV/A/m | mV/A/m | mV/A/m | ||||

1.5 | 31 | 31 | 27 | ||||

2.5 | 19 | 19 | 16 | ||||

4.0 | 12 | 12 | 10 | ||||

6.0 | 7.9 | 7.9 | 6.8 | ||||

10 | 4.7 | 4.7 | 4.0 | ||||

16 | 2.9 | 2.9 | 2.5 | ||||

|

| r | x | z | r | x | z |

25 | 1.85 | 1.85 | 0.160 | 1.90 | 1.60 | 0.140 | 1.65 |

35 | 1.35 | 1.35 | 0.155 | 1.35 | 1.15 | 0.135 | 1.15 |

50 | 0.98 | 0.99 | 0.155 | 1.00 | 0.86 | 0.135 | 0.87 |

70 | 0.67 | 0.67 | 0.150 | 0.69 | 0.59 | 0.130 | 0.60 |

95 | 0.49 | 0.50 | 0.150 | 0.52 | 0.43 | 0.130 | 0.45 |

120 | 0.39 | 0.40 | 0.145 | 0.42 | 0.34 | 0.130 | 0.37 |

150 | 0.31 | 0.32 | 0.145 | 0.35 | 0.28 | 0.125 | 0.30 |

185 | 0.25 | 0.26 | 0.145 | 0.29 | 0.22 | 0.125 | 0.26 |

240 | 0.195 | 0.200 | 0.140 | 0.24 | 0.175 | 0.125 | 0.21 |

300 | 0.155 | 0.160 | 0.140 | 0.21 | 0.140 | 0.120 | 0.185 |

400 | 0.120 | 0.130 | 0.140 | 0.190 | 0.115 | 0.120 | 0.165 |

Note: *Spacings larger than one cable diameter will result in a large voltage drop.

r = conductor resistance at operating temperature

x = reactance

z = impedance

Introduction

In modern electrical engineering, the demand for reliable, efficient, and safe power transmission solutions is paramount. The 600/1000V XLPE insulated, PVC sheathed, unarmoured power cables, designed to meet the International Electrotechnical Commission (IEC) 60502-1 standard, are a cornerstone of power distribution systems globally. These cables are widely used in critical infrastructure, including power stations, mass transit systems, and high-rise buildings. In South Africa, where rapid urbanisation and industrial growth drive the need for robust electrical systems, these cables play a pivotal role.

Fire Performance and Approvals

The cables are designed to meet stringent fire performance standards, including IEC 60332-1 for flame retardance in single vertical wire tests. Depending on the PVC compound's oxygen index and overall cable design, compliance with additional standards like IEC 60332-3, UL 1581, and UL 1666 can be achieved. Low-smoke PVC (LSPVC) options are available for applications requiring reduced smoke emission during fires, such as in enclosed public spaces. The cables hold TÜV certification (Z1 17 01 98200 004), affirming their quality and compliance with international standards.

Applications

These cables are versatile, serving critical infrastructure across various sectors:

Power Stations: Their high current-carrying capacity and thermal resilience make them ideal for power distribution within generation facilities.

Mass Transit Systems: Used in underground passenger systems for reliable power supply to lighting, signalling, and ventilation.

Airports and Petrochemical Plants: Their optional resistance to hydrocarbons and UV radiation ensures durability in harsh environments.

Hospitals and Hotels: Fire performance features, such as flame retardance and low-smoke options, enhance safety in densely populated areas.

High-Rise Buildings: The cables’ flexibility and compliance with fire standards make them suitable for complex electrical networks in tall structures.

South African Case Studies

Case Study 1: Medupi Power Station

The Medupi Power Station, one of South Africa’s largest coal-fired power plants, relies on 600/1000V XLPE insulated cables for its internal power distribution. In 2023, a significant upgrade to the plant’s auxiliary power systems incorporated these cables to enhance reliability. The cables’ ability to handle high short-circuit temperatures (up to 250°C) and their compliance with IEC 60332-1 ensured safe operation in the demanding environment of a power station. The project reduced downtime by 15%, demonstrating the cables’ effectiveness in high-stakes applications.

Case Study 2: Gautrain Expansion

The Gautrain, South Africa’s high-speed rail network, underwent an expansion in 2024 to include new stations in Johannesburg. The project utilised 600/1000V XLPE insulated, PVC sheathed cables for powering signalling and station facilities. The cables’ flame-retardant properties and availability in multicore configurations (up to 48 cores) allowed for efficient installation in confined underground spaces. The use of LSPVC sheaths in passenger areas minimised risks associated with smoke inhalation, aligning with safety regulations for public transport systems.

Case Study 3: Cape Town High-Rise Development

In 2025, a new high-rise commercial building in Cape Town’s central business district adopted these cables for its electrical backbone. The project required cables with UV-resistant sheaths due to exposure to South Africa’s intense sunlight. The four-core and five-core configurations facilitated the building’s complex power distribution needs, while the cables’ compliance with BS 7671 ensured adherence to local electrical standards. The installation contributed to the building achieving a Green Star SA rating, highlighting the cables’ role in sustainable infrastructure.

Advantages and Limitations

Advantages

Durability: XLPE insulation and PVC sheathing provide excellent resistance to thermal, mechanical, and environmental stresses.

Versatility: Available in multiple core configurations and conductor sizes, these cables suit a wide range of applications.

Safety: Compliance with fire performance standards and optional low-smoke properties enhance safety in public spaces.

Customisation: Options for UV resistance, oil resistance, and anti-rodent features cater to specific environmental challenges.

Limitations

Cost: XLPE insulation and optional sheath properties can increase costs compared to simpler cable types.

Installation Complexity: The minimum bending radius of 12 times the overall diameter may pose challenges in tight spaces.

Voltage Drop: In long cable runs, careful selection of conductor size is necessary to manage voltage drop effectively.

The 600/1000V XLPE insulated, PVC sheathed, unarmoured power cables to IEC 60502-1 are a robust solution for modern power distribution needs. Their superior construction, compliance with international standards, and adaptability to harsh environments make them indispensable in critical infrastructure. In South Africa, their application in projects like Medupi Power Station, Gautrain, and high-rise developments underscores their reliability and versatility. As the country continues to invest in sustainable and safe infrastructure, these cables will remain a cornerstone of electrical engineering, balancing performance, safety, and cost-effectiveness.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430