Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

600/1000V XLPE Insulated, PVC Sheathed, Unarmoured Power Cables to IEC 60502 (Single Core)

Application

IEC 60502-1 600/1000V XLPE Insulated, PVC Sheathed Unarmoured Power Cables are mainly use in fixed installations in industrial areas, buildings and similar applications but not for burial in the ground, either directly or in ducts.

Standards

Basic design to to IEC 60502-1

Fire Performance

Flame Retardance (Single Vertical Wire Test) | IEC 60332-1-2 |

Voltage Rating

600/1000V

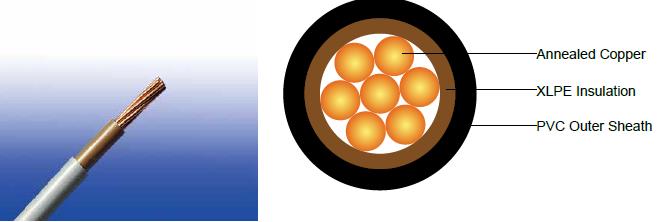

Cable Construction

Conductor | Plain annealed copper, stranded according to IEC 60228 class 2. |

Insulation | XLPE according to IEC 60502-1. |

Outer Sheath | Extruded PVC Type ST1/ST2 according to IEC 60502-1. |

Outer Sheath Option | UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option. Compliance to fire performance standard (IEC 60332-1, IEC 60332-3, UL 1581, UL 1666 etc) depends on the oxygen index of the PVC compound and the overall cable design. LSPVC can also be provided upon request. |

Colour Code

Insulation Colour | Brown or blue, other colours can be offered upon request. |

Sheath Colour | Black, other colours can be offered upon request. |

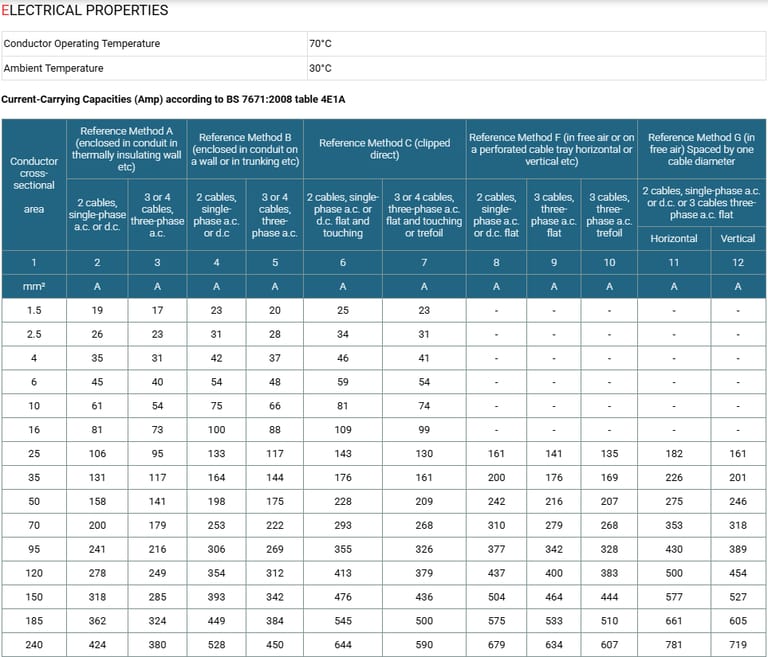

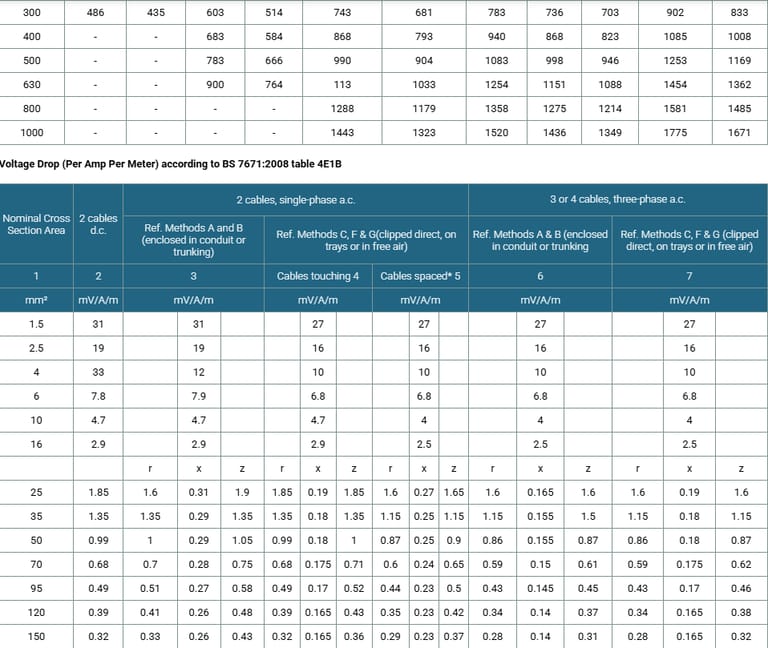

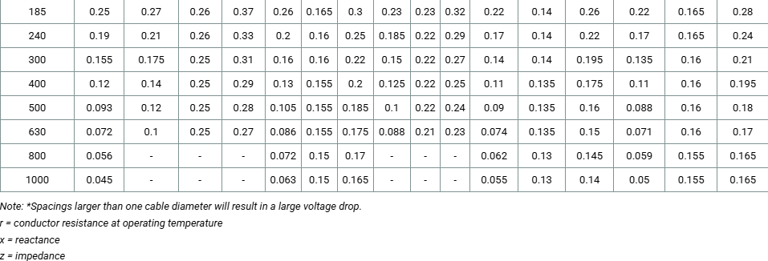

Mechanical and Electrical Properties

Maximum temperature range during operation | 80°C (For ST1 Sheath); 90°C (For ST2 Sheath) | ||||||||||

Maximum short circuit temperature (5 Seconds) | 250°C | ||||||||||

Minimum bending radius |

| ||||||||||

| |||||||||||

Construction Parameters

Conductor | FGD300 1RV-R | ||||

|---|---|---|---|---|---|

No. of Cores x Cross Section | Class of Conductor | Nominal Insulation Thickness | Nominal Sheath Thickness | Nominal Overall Diameter | Approx. Weight |

No.xmm2 |

| mm | mm | mm | kg/km |

2 | 0.7 | 1.4 | 6.1 | 36 | |

2 | 0.7 | 1.4 | 6.8 | 52 | |

2 | 0.7 | 1.4 | 7.4 | 76 | |

2 | 0.7 | 1.4 | 8.2 | 100 | |

2 | 0.7 | 1.4 | 9.2 | 160 | |

2 | 0.7 | 1.4 | 10.7 | 230 | |

2 | 0.9 | 1.4 | 12.5 | 340 | |

2 | 0.9 | 1.4 | 13.5 | 440 | |

2 | 1 | 1.4 | 13.7 | 541 | |

2 | 1.1 | 1.4 | 15.8 | 749 | |

2 | 1.1 | 1.5 | 17.5 | 1000 | |

2 | 1.2 | 1.5 | 19.3 | 1241 | |

2 | 1.4 | 1.6 | 21.5 | 1523 | |

2 | 1.6 | 1.6 | 24.7 | 1942 | |

2 | 1.7 | 1.7 | 27.7 | 2514 | |

2 | 1.8 | 1.8 | 30.6 | 3125 | |

2 | 2 | 1.9 | 34.2 | 3967 | |

2 | 2.2 | 2 | 38 | 5063 | |

2 | 2.4 | 2.2 | 42.9 | 6491 | |

2 | 2.6 | 2.3 | 46 | 8075 | |

2 | 2.8 | 2.4 | 63 | 9860 | |

Introduction

In the realm of electrical engineering, power cables form the backbone of modern infrastructure, ensuring reliable transmission and distribution of electricity across various sectors. Among these, the 600/1000V XLPE insulated, PVC sheathed unarmoured power cables, designed to IEC 60502-1 standards, stand out for their robustness and versatility in low-voltage applications. These single-core cables are particularly suited for fixed installations in industrial areas, buildings, and similar environments, though not recommended for direct burial in the ground or ducts due to their unarmoured construction.

Cross-linked polyethylene (XLPE) insulation offers superior thermal and electrical properties compared to traditional materials like PVC, making these cables a preferred choice for demanding scenarios. With a voltage rating of 600/1000V, they cater to systems where reliability under moderate voltage stress is paramount. This article provides an in-depth analysis of their construction, mechanical and electrical properties, and usage scenarios, drawing on technical data and incorporating recent case studies from South Africa. As the country grapples with energy challenges, including load shedding and infrastructure upgrades, these cables play a crucial role in enhancing efficiency and sustainability.

South Africa's electrical standards often align with international norms like IEC, supplemented by local SANS (South African National Standards) equivalents, ensuring compatibility and safety. The analysis herein adheres to South African language conventions, emphasising practical insights for engineers, installers, and policymakers.

Applications and Usage Scenarios

Primarily for fixed installations in buildings and industries, these cables excel in power distribution panels, lighting circuits, and machinery feeds. Their unarmoured nature suits protected environments, avoiding mechanical stress.

In South Africa, applications span commercial retrofits for energy efficiency, industrial plants, and renewable integrations. Coastal innovations, like Aberdare Cables' MV XLPE designs for wet lands, extend principles to low-voltage counterparts. Non-destructive testing methods developed in 2025 enhance maintenance.

Conclusion

The 600/1000V XLPE insulated, PVC sheathed unarmoured power cables to IEC 60502-1 exemplify engineering excellence, balancing performance, safety, and adaptability. Their electrical and mechanical properties support diverse applications, while South African case studies highlight real-world efficacy. As the nation advances towards greener energy, these cables will remain pivotal, driving efficiency and resilience.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430