Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

6241B/6242B/ 6243B, LSOH Flat Wiring Cables with circuit protective conductor

APPLICATION AND DESCRIPTION

These cables are suitable for fixed installation particularly for situations in which low emission smoke and domestic wiring cable for the surface wiring of sockets and lighting where fire, smoke emission and toxic fumes create a potential threat to life and equipment. Can be installed in fixed installations in dry or damp premises on walls, boards or trays, in channels or embedded in plaster. Suitable for laying in conduit or trunking where mechanical protection is required.

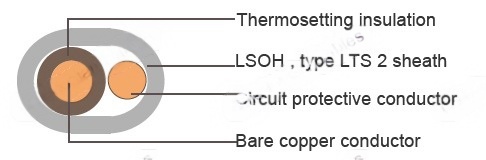

CABLE CONSTRUCTION

Fine bare copper strands

Strands to IEC 60228 Cl-1 or 2

Thermosetting core insulation type EI5 or GP 8

The core or cores shall be laid parallel with the uninsulated circuit protective conductor

For twin cores, the protective conductor centrally placed between cores in same plane

For 3 cores, the protective conductor centrally placed between black and grey cores in same plane

LSOH sheath, type LTS 2

INSULATION COLOUR

Single core: brown or blue Twin: brown and blue, or, for 2 × 1.0 and 2 × 1.5 cables, brown and brown 3-core: brown, black (centre core) and grey

TECHNICAL CHARACTERISTICS

Working voltage : 300/500v

Test voltage : 2000 volts

Flexing bending radius : 15 x Ø

Static bending radius : 10 x Ø

Flexing temperature : +5ºC to +90ºC

Short circuit temperature : +250ºC

Flame retardant : IEC 60332.1

Insulation resistance : 10 MΩ x km

Smoke density acc. to EN 50268 / IEC 61034

Corrosiveness of combustion gases acc. to EN 50267-2-2, IEC 60754-2

Flame test : flame-retardant acc. to EN 50265-2-1, IEC 60332.1

CABLE PARAMETER

AWG | No. of Cores x Nominal Cross Sectional Area | Nominal Thickness Of Insulation | Nominal Thickness Of Sheath | Nominal Overall Dimensions | Circuit Protective Conductor | Nominal Weight | Minimum Insulation Resistance at 90 °C | |

|---|---|---|---|---|---|---|---|---|

lower limit | upper limit | |||||||

# x mm² | mm | mm | mm | mm | AWG | kg/km | MΩ·km | |

6242B | ||||||||

17 | 0.7 | 0.9 | 4.1 × 7.6 | 5.0 × 9.1 | 17 | 68 | 0.011 | |

17(7/26) | 0.7 | 0.9 | 4.2 × 7.8 | 5.1 × 9.4 | 17 | 73 | 0.011 | |

16 | 0.7 | 0.9 | 4.4 × 8.1 | 5.3 × 9.7 | 17 | 85 | 0.011 | |

16(7/24) | 0.7 | 0.9 | 4.5 × 8.3 | 5.4 × 10.0 | 17 | 90 | 0.011 | |

14 | 0.7 | 1.0 | 4.9 × 9.3 | 6.0 × 11.2 | 16 | 120 | 0.0092 | |

14(7/22) | 0.7 | 1.0 | 5.0 × 9.5 | 6.1 × 11.4 | 16 | 125 | 0.0084 | |

12(7/20) | 0.7 | 1.0 | 5.5 × 10.4 | 6.7 × 12.6 | 16 | 175 | 0.0070 | |

10(7/18) | 0.7 | 1.1 | 6.2 × 12.0 | 7.5 × 14.6 | 14 | 240 | 0.0059 | |

8(7/16) | 0.7 | 1.2 | 7.3 × 14.5 | 8.8 × 17.6 | 12(7/20) | 390 | 0.0047 | |

6(7/14) | 0.7 | 1.3 | 8.4 × 17.0 | 10.1 × 20.5 | 10(7/18) | 560 | 0.0039 | |

6243B | ||||||||

17 | 0.7 | 0.9 | 4.1 × 10.0 | 5.1 × 12.1 | 17 | 91 | 0.011 | |

16 | 0.7 | 0.9 | 4.4 × 10.7 | 5.3 × 12.9 | 17 | 115 | 0.011 | |

14 | 0.7 | 1.0 | 4.9 × 12.0 | 6.0 × 14.6 | 17 | 170 | 0.0092 | |

12(7/20) | 0.7 | 1.0 | 5.5 × 14.0 | 6.7 × 16.9 | 16 | 196 | 0.0070 | |

10(7/18) | 0.7 | 1.1 | 6.2 × 16.2 | 7.5 × 19.5 | 14 | 291 | 0.0059 | |

8(7/16) | 0.7 | 1.2 | 7.3 × 19.5 | 8.8 × 23.6 | 12(7/20) | 440 | 0.0047 | |

6(7/14) | 0.7 | 1.3 | 8.4 × 22.8 | 10.1 × 27.6 | 10(7/18) | 670 | 0.0039 | |

Understanding LSOH Technology

Low Smoke Zero Halogen (LSOH) cables are engineered to limit the emission of smoke and corrosive gases when exposed to fire. Unlike traditional PVC cables, which contain halogens like chlorine that produce toxic hydrochloric acid upon burning, LSOH materials use halogen-free compounds. This results in clearer visibility during evacuations and less damage to equipment from acid corrosion. The technology stems from international standards like IEC 60332 for flame retardancy and IEC 61034 for smoke density, ensuring compliance in high-risk areas.

In scientific terms, LSOH sheaths are typically made from thermoplastic or thermosetting polymers infused with flame-retardant additives. When heated, they char rather than melt, forming a protective barrier that slows fire spread. Studies show that LSOH cables can reduce smoke production by up to 80% compared to PVC, significantly improving survival rates in fire incidents. For flat wiring cables like the 624 series, this technology is integrated into a compact, easy-to-install design, making them suitable for surface wiring in sockets and lighting circuits.

The inclusion of a circuit protective conductor (CPC) – often a bare copper earth wire – adds another layer of safety. It provides a low-impedance path for fault currents, preventing electric shocks and ensuring circuit breakers trip promptly. This combination of LSOH properties and CPC makes these cables indispensable in modern electrical systems, where reliability and safety are non-negotiable.

In-Depth Analysis of 6241B, 6242B, and 6243B

The 6241B is a single-core variant with CPC, ideal for simple earthing or phase connections in switchboards. Its compact size (e.g., 1.0 mm²: dimensions approx. 4.0 × 6.0 mm) suits tight spaces, with weights around 50 kg/km for easy handling. Analysis shows it excels in low-load applications, offering insulation resistance of 0.011 MΩ·km.

The 6242B, twin-core with CPC, is the workhorse for lighting and socket circuits. In fire scenarios, its LSOH sheath reduces toxicity, with studies indicating 50% less acid gas emission than PVC equivalents. For 2.5 mm², it supports currents up to 27A, balancing capacity and flexibility.

The 6243B, with three cores, caters to three-phase or complex wiring, like in distribution boards. Its central CPC placement ensures even fault protection. Comparative analysis reveals superior tensile strength, making it resilient in vibrational environments. All variants share BS 7211 compliance, which specifies thermosetting insulation for enhanced thermal stability.

Applications in Building Wiring

These cables find extensive use in fixed installations for surface wiring of sockets and lighting. In dry or damp premises, they can be clipped to walls, laid in trays, or embedded in plaster. Mechanical protection via conduits makes them versatile for commercial buildings. In South Africa, they align with SANS 10142-1 wiring codes, particularly in public spaces where low smoke is mandated.

For instance, in hospitals or schools, 6242B cables power emergency lighting, reducing evacuation hazards. Commercial applications include office wiring, where their flat design minimises disruption during retrofits. Not suitable for outdoors due to non-UV resistant sheaths, they thrive indoors, supporting sustainable building practices.

Advantages Over Traditional PVC Cables

LSOH cables offer superior fire safety, emitting no halogens and low smoke, which can save lives by maintaining visibility. They also boast higher temperature tolerance and environmental friendliness, with no toxic byproducts. While initially costlier, their longevity and reduced maintenance yield better ROI. In corrosive environments, LSOH prevents equipment damage, extending system life.

FAQs

What is the difference between 6242B and 6242Y cables?

The 6242B uses LSOH materials for low smoke, while 6242Y is PVC-based, releasing more toxins in fires.

Can these cables be used in damp areas?

Yes, in fixed installations in dry or damp premises, but not in wet outdoor conditions.

Why include a circuit protective conductor?

It provides earthing to prevent shocks and ensure fault protection.

Are LSOH cables more expensive?

Initially yes, but they offer long-term savings through safety and durability.

What sizes are available?

From 1.0 mm² to 16 mm², depending on the variant.

LSOH flat wiring cables like 6241B, 6242B, and 6243B with circuit protective conductor are vital for safer, more reliable electrical systems. Their design prioritises fire safety, making them essential in today's buildings. As regulations evolve, adopting these cables ensures compliance and peace of mind.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430