Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

6.35/11kV XLPE Insulated, MDPE Sheathed, Armoured MV Power Cables (Three Cores)

Application

They are suitable for installation mostly in power supply stations, indoors and in cable ducts, outdoors, underground and in water as well as for installation on cable trays for industries, switchboards and power stations.

Standards

Basic design adapted to IEC 60502-2

Construction

Conductor : Plain annealed copper wire, stranded according to IEC/BS EN 60228 class 2..

Conductor Screen : Extruded layer of semi-conducting cross-linkable compound is applied over the conductor and shall cover the surface completely.

Insulation : Extruded cross-linked polyethylene (XLPE) according to IEC 60502-2&IEC 60811.

Insulaton Screen : Extruded layer of semi-conducting cross-linkable compound is applied over the insulation.

Inner Covering & Fillers : Cables shall have an inner covering over the laid-up cores. The inner covering and fillers are made of non hygroscopic material like polypropylene, except if the cable is to be made longitudinally watertight. The inner covering is extruded in general but may be lapped if the interstices between the cores are filled.

Metallic Screen : The metallic layer shall be applied over each core or applied as a collective screen. The metallic screen shall consist of either copper tapes or a concentric layer of copper wires or a combination of tapes and wires.

Separation Sheath : Thermoplastic PVC compound.

Waterproof : Water blocking tape

Bedding : Thermoplastic PVC compound.

Armour : Round Steel Wire or Steel Tape Armour

Outer Sheath : Thermoplastic MDPE compound Type ST7 according to IEC 60502-2.

COLOUR CODE

Insulation Colour : Natural colouring with coloured stripe (brown, black, grey)

Sheath Colour : Red, other colours can be offered upon request.

PHYSICAL PROPERTIES

Operating Temperature : up to 90°C

Temperature Range : -5°C

Short Circuit Temperature( 5 seconds maximum duration ) : 250°C

Bending Radius : 15 x OD

Nominal /Operating /Testing Voltages

Rated Voltage Uo/U | Operating Voltage (Um) | Testing Voltage (rms) |

|---|---|---|

6.35/11KV | 12KV | 25.5KV |

DIMENSIONAL DATA

N2XSEYR2Y (CU/XLPE/CS/PVC/SWA/PE 6.35/11kV Class 2)

Nom. Cross-Section Area | Nom. Insulation Thickness | Metallic Screen Area | Nom. Bedding Thickness | Armour wire Diameter | Nom. Sheath Thickness | Approx. Overall Diameter | Approx. Weight |

|---|---|---|---|---|---|---|---|

mm² | mm | mm² | mm | mm | mm | mm | kg/km |

3.4 | 16 | 1.2 | 2.0 | 2.4 | 42.4 | 3000 | |

3.4 | 16 | 1.3 | 2.5 | 2.5 | 46.7 | 3900 | |

3.4 | 16 | 1.3 | 2.5 | 2.6 | 49.3 | 4430 | |

3.4 | 16 | 1.4 | 2.5 | 2.7 | 52.6 | 5080 | |

3.4 | 16 | 1.5 | 2.5 | 2.8 | 56.9 | 6050 | |

3.4 | 16 | 1.5 | 2.5 | 2.9 | 61.2 | 7180 | |

3.4 | 16 | 1.6 | 2.5 | 3.0 | 65.9 | 8230 | |

3.4 | 25 | 1.7 | 2.5 | 3.1 | 69.6 | 9380 | |

3.4 | 25 | 1.7 | 3.15 | 3.3 | 75.4 | 11610 | |

3.4 | 25 | 1.8 | 3.15 | 3.5 | 82.5 | 14110 | |

3.4 | 25 | 1.9 | 3.15 | 3.7 | 88.3 | 16420 | |

3.4 | 35 | 2.0 | 3.5 | 3.9 | 96.0 | 20620 |

N2XSEYB2Y (CU/XLPE/CS/PVC/STA/PE 6.35/11kV Class 2)

Nom. Cross-Section Area | Nom. Insulation Thickness | Metallic Screen Area | Nom. Bedding Thickness | Armour tape Thickness | Nom. Sheath Thickness | Approx. Overall Diameter | Approx. Weight |

|---|---|---|---|---|---|---|---|

mm² | mm | mm² | mm | mm | mm | mm | kg/km |

3.4 | 16 | 1.2 | 0.5 | 2.3 | 40.5 | 2680 | |

3.4 | 16 | 1.3 | 0.5 | 2.4 | 43.7 | 3195 | |

3.4 | 16 | 1.3 | 0.5 | 2.5 | 46.2 | 3720 | |

3.4 | 16 | 1.4 | 0.5 | 2.6 | 48.8 | 4200 | |

3.4 | 16 | 1.5 | 0.5 | 2.7 | 52.8 | 5185 | |

3.4 | 16 | 1.5 | 0.5 | 2.8 | 56.9 | 6280 | |

3.4 | 16 | 1.6 | 0.5 | 2.9 | 60.5 | 7360 | |

3.4 | 25 | 1.7 | 0.5 | 3.0 | 63.9 | 8420 | |

3.4 | 25 | 1.7 | 0.5 | 3.1 | 68.2 | 9910 | |

3.4 | 25 | 1.8 | 0.5 | 3.3 | 73.8 | 12200 | |

3.4 | 25 | 1.9 | 0.5 | 3.4 | 79.1 | 14530 | |

3.4 | 35 | 2.0 | 0.8 | 3.7 | 87.7 | 18600 |

Introduction

Medium-voltage (MV) power cables are the backbone of modern electrical distribution systems, facilitating the reliable transmission of electricity from power stations to industrial, commercial, and residential users. In South Africa, where rapid urbanisation and industrial growth demand robust and efficient energy solutions, cables rated at 6.35/11kV play a crucial role in bridging the gap between high-voltage transmission lines and low-voltage end-user applications. This article delves into the specifics of three-core XLPE (cross-linked polyethylene) insulated, MDPE (medium-density polyethylene) sheathed, armoured MV power cables, such as the N2XSEYR2Y and N2XSEYB2Y variants. These cables are designed for durability, safety, and performance in diverse environments, from underground installations to overhead cable trays.

Overview of Medium-Voltage Power Cables

Medium-voltage cables typically operate between 1kV and 33kV, with the 6.35/11kV rating being a standard for many distribution networks in South Africa. The "6.35/11kV" designation indicates a phase-to-earth voltage (Uo) of 6.35kV and a phase-to-phase voltage (U) of 11kV, with a maximum operating voltage (Um) of 12kV. These cables are essential for power supply stations, switchboards, and industries, where they handle significant loads while minimising losses.

In South Africa, the electricity sector faces unique challenges, including frequent load shedding, mining operations in remote areas, and the integration of renewable energy sources like solar and wind farms. XLPE-insulated cables have gained prominence due to their superior thermal and electrical properties compared to older PVC or paper-insulated types. The armouring—either steel wire or tape—provides mechanical protection against external damage, making them ideal for buried or ducted installations in urban Johannesburg or rural KwaZulu-Natal.

Applications in Various Environments

These cables excel in power stations, indoors, cable ducts, outdoors, underground, and water submersion, plus cable trays for industries and switchboards. In South Africa, they're used in Eskom's distribution networks, mining operations in Mpumalanga, and renewable integrations in the Western Cape.

Armouring protects against mechanical stress in construction zones, while waterproofing suits flood-prone areas. Their versatility supports the country's energy transition goals.

Advantages of XLPE Insulation

XLPE outperforms PVC by withstanding higher temperatures (90°C vs. 70°C), reducing derating in hot climates. It's lighter, more flexible, and environmentally friendlier, with lower smoke emission in fires—a key safety feature in confined spaces like tunnels.

In South Africa, where temperatures can exceed 40°C, XLPE minimises thermal expansion issues, extending cable life beyond 30 years.

Comparison with Other Cable Types

Compared to PILC (paper-insulated lead-covered) cables, XLPE types are easier to install, require no lead (reducing environmental impact), and handle higher fault currents. Versus EPR (ethylene propylene rubber), XLPE offers better water resistance but similar electrical properties.

In South African contexts, armoured XLPE cables are preferred over unarmoured for buried applications due to wildlife and vandalism risks.

Frequently Asked Questions on Medium-Voltage Power Cables

What is the maximum voltage these cables can handle? Rated at 6.35/11kV, they operate up to 12kV, with testing at 25.5kV, ensuring reliability in fluctuating South African grids.

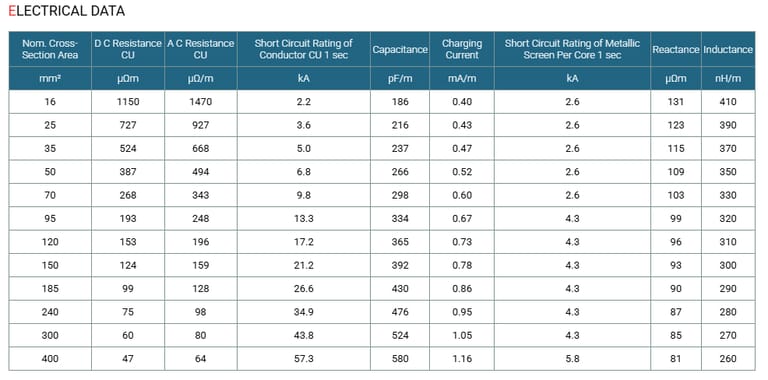

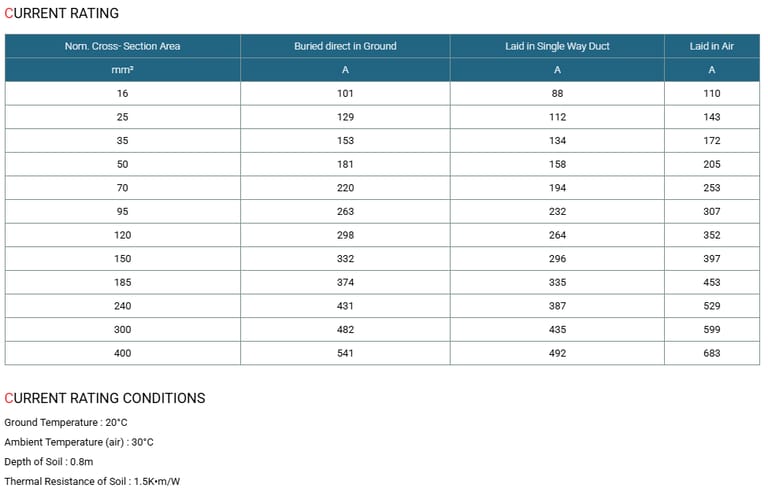

How do I select the right cross-section? Based on load: e.g., 95mm² for 263A buried, considering derating for depth or grouping.

Are they suitable for underwater installation? Yes, with water-blocking tapes and MDPE sheaths, ideal for river crossings or coastal projects.

What maintenance is required? Periodic inspections for damage; XLPE's durability minimises needs, but monitor for overheating in high-load scenarios.

How do environmental factors affect performance? High humidity may require sealed joints; in arid areas, UV-resistant sheaths prevent cracking.

Can colours be customised? Yes, sheaths beyond red are available, aiding identification in multi-cable setups.

What are the short-circuit implications? High ratings protect systems; coordinate with breakers for safe operation.

How do they contribute to energy efficiency? Low resistance and capacitance reduce losses, supporting South Africa's energy-saving initiatives.

The 6.35/11kV XLPE insulated, MDPE sheathed, armoured MV power cables represent a pinnacle of engineering for reliable power distribution. Their robust construction, adherence to standards, and adaptability to South African conditions make them indispensable for sustaining economic growth. As the nation advances towards a sustainable energy future, investing in such technologies ensures resilience against challenges like climate variability and increasing demand. Engineers should prioritise these cables for their balance of performance, safety, and cost-effectiveness, ultimately powering a brighter South Africa.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430