Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

6491B Conduit Wiring Cable

APPLICATION AND DESCRIPTION

6491B is equivalent to harmonized code H07Z-R, these cables are designed for fixed wiring purposes in domestic and industrial power/ lighting applications. Can be used in trunking or conduit, or may be surface mounted when used for earthing. and generally in areas (such as public and government buildings) where smoke and toxic fumes may cause a threat to life and equipment. The cables produce no corrosive gasses when burnt which is particularly important where electronic equipment is installed.

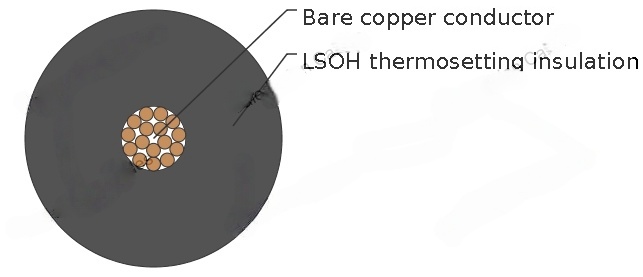

CABLE CONSTRUCTION

Strands to IEC 60228 Cl-2 LSOH thermosetting insulation

Thermosetting core insulation type EI5

LSOH - low smoke, zero halogen

INSULATION COLOUR

Black, Blue, Green/Yellow, Red, Yellow, White, Violet, Brown, Grey, Orange, Pink

TECHNICAL CHARACTERISTICS

Working voltage : 450/750v

Test voltage : 2500 volts

Minimum bending radius : up to 10 mm² - 3 x overall diameter,above 25 mm² -6 x overall diameter

Flexing temperature : 0ºC to +90ºC

Short circuit temperature : +250ºC

Insulation resistance : 10 MΩ x km

Flame retardant : IEC 60332.1

Smoke density acc. to EN 50268 / IEC 61034

Corrosiveness of combustion gases acc. to EN 50267-2-2, IEC 60754-2

Flame test : flame-retardant acc. to EN 50265-2-1, IEC 60332.1

CABLE PARAMETER

AWG | No. Of Cores × Nominal Cross Sectional Area | Nominal Thickness Of Insulation | Nominal Overall Diameter | Nominal Copper Weight | Nominal Weight | Minimum Insulation Resistance At 90 °C |

|---|---|---|---|---|---|---|

# × mm² | mm | mm | kg/km | kg/km | mΩ·km | |

16(7/24) | 0.7 | 2.7-3.4 | 14.4 | 21 | 0.010 | |

14(7/22) | 0.8 | 3.3-4.1 | 24 | 33 | 0.009 | |

12(7/20) | 0.8 | 3.8-4.7 | 39 | 49 | 0.0077 | |

10(7/18) | 0.8 | 4.3-5.4 | 58 | 71 | 0.0065 | |

8(7/16) | 1 | 5.6-7.0 | 94 | 114 | 0.0065 | |

6(7/14) | 1 | 6.4-8.0 | 154 | 172 | 0.0050 | |

4(7/12) | 1.2 | 8.1-10.1 | 240 | 265 | 0.0050 | |

2(7/10) | 1.2 | 9.0-11.3 | 350 | 397 | 0.0043 | |

1(19/13) | 1.4 | 10.6-13.2 | 480 | 534 | 0.0043 | |

2/0(19/11) | 1.4 | 12.1-15.1 | 672 | 830 | 0.0035 | |

3/0(19/10) | 1.6 | 14.1-17.6 | 912 | 1054 | 0.0035 | |

4/0(37/12) | 1.6 | 15.6-19.4 | 1152 | 1274 | 0.0032 | |

300MCM(37/11) | 1.8 | 17.3-21.6 | 1440 | 1604 | 0.0032 | |

350MCM(37/10) | 2.0 | 19.3-24.1 | 1776 | 2030 | 0.0032 | |

500MCM(61/11) | 2.2 | 22.0-27.5 | 2400 | 2630 | 0.0032 | |

-(61/10) | 2.4 | 24.5-30.6 | 3010 | 3330 | 0.0030 | |

-(61/9) | 2.6 | 27.5-34.3 | 3820 | 4190 | 0.0028 | |

-(61/8) | 2.8 | 30.5-38.2 | 4800 | 5240 | 0.0028 | |

-(127/10) | 2.8 | 34.0-42.5 | 6350 | 6820 | 0.0025 |

Applications and Practical Implementation

The 6491B's versatility extends across multiple sectors. In domestic wiring, it's ideal for conduit installations in homes, providing safe power to lighting and appliances. Its surface-mounting capability for earthing simplifies retrofits in older buildings. Industrially, it's used in factories and warehouses where electronic controls are prevalent, as LSOH prevents corrosion of sensitive PLCs and sensors during fires.

In public infrastructure, such as South African government buildings or metros like Johannesburg's Gautrain, the cable ensures compliance with SANS 10142-1 wiring codes, which emphasise fire-resistant materials. Healthcare facilities leverage its low smoke properties to safeguard patients during emergencies, while data centres use it to protect servers from corrosive fumes.

Installation best practices include adhering to the bending radius to avoid insulation cracks. For larger sizes like 1 x 240 mm², with diameters up to 27.5 mm, proper trunking sizing is essential. Weight considerations—up to 6820 kg/km for 1 x 630 mm²—impact handling and support structures. Compared to armoured cables, the 6491B is lighter and more flexible, suiting non-mechanical stress environments.

Economically, while initial costs may be higher than PVC alternatives, long-term savings arise from reduced maintenance and insurance premiums due to enhanced safety. In South Africa, with frequent load-shedding, the cable's durability ensures resilience against voltage fluctuations.

Environmental and Sustainability Insights

Beyond safety, the 6491B contributes to environmental stewardship. Halogen-free insulation reduces the ecological footprint, as manufacturing avoids chlorine-based compounds. During its lifecycle, from production to disposal, it emits fewer pollutants. Copper conductors are fully recyclable, with high scrap value encouraging responsible end-of-life management.

In the context of climate change, LSOH cables like this support green building certifications such as EDGE or Green Star in South Africa. By minimising fire-related emissions, they indirectly lower carbon footprints in disaster scenarios. However, challenges include higher raw material costs for thermosetting polymers, though advancements in bio-based LSOH compounds may address this.

Comparative Analysis with Other Cables

When compared to standard H07V-R (PVC-insulated) cables, the 6491B excels in fire performance but may have slightly lower flexibility in extreme cold. Versus XLPE-insulated variants, it offers similar thermal ratings but superior halogen-free properties. In marine or offshore applications, while not specifically designed, its LSOH could complement standards like IEC 60092.

South African users might contrast it with local equivalents under SANS 1507, noting the 6491B's international harmonisation provides export advantages for manufacturers.

Frequently Asked Questions (FAQs)

What is the primary advantage of the 6491B cable's LSOH insulation?

The LSOH (low smoke zero halogen) insulation ensures minimal smoke and no corrosive gases during combustion, protecting lives and equipment in fire-prone areas.

Can the 6491B be used outdoors?

It's primarily for indoor fixed wiring in conduits or trunking. For outdoor use, additional protection against UV and moisture is recommended.

How does the cable's size affect its bending radius?

For cross-sections up to 10 mm², the minimum radius is 3x overall diameter; above 25 mm², it's 6x, ensuring safe installation without stress.

What colours are available for insulation?

Options include black, blue, green/yellow, red, yellow, white, violet, brown, grey, orange, and pink for easy identification.

Is the 6491B compliant with South African standards?

Yes, it aligns with SANS 10142-1 for wiring and international IEC norms, making it suitable for local installations.

What is the maximum short-circuit temperature?

It can withstand +250°C, providing a safety margin during faults.

How does insulation resistance vary with temperature?

At 90°C, it ranges from 0.010 MΩ·km for 1.5 mm² to 0.0025 MΩ·km for 630 mm², ensuring low leakage.

Can it be used for high-voltage applications?

No, it's rated for 450/750V working voltage; for higher, specialised cables are needed.

What AWG sizes are available?

From 16 AWG (1.5 mm²) to heavier like 500 MCM (240 mm²) and beyond, covering a wide range.

How heavy is the cable for large installations?

For 1 x 630 mm², it's about 6820 kg/km, requiring robust support systems.

The 6491B conduit wiring cable exemplifies innovation in electrical materials, blending technical prowess with safety and sustainability. Its LSOH design addresses critical fire risks, making it indispensable in modern infrastructure. Whether for domestic, industrial, or public use, it offers reliability backed by stringent standards. As South Africa advances towards safer, greener electrical systems, cables like the 6491B will play a pivotal role. By understanding its multifaceted benefits, installers and engineers can make informed choices that prioritise protection and performance.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430