Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

6491X / H07V-R / H07V-U EN 50525-2-31 Cable

Category | Details |

|---|---|

Application | Suitable for power and lighting circuits, building wiring. Intended for use in semi-flush exposed conduits, embedded conduits, closed installation ducts, and internal wiring of appliances. |

Voltage Rating (Uo/U) | 450/750V |

Temperature Rating | -15°C to +70°C |

Minimum Bending Radius | Up to 10mm²: 3 x overall diameter 10mm² to 25mm²: 4 x overall diameter Above 25mm²: 5 x overall diameter |

Conductor | Class 2 stranded copper conductor (5mm² to 10mm² also available as H07V-U Class 1 solid copper conductor) |

Insulation | PVC (Polyvinyl Chloride) |

Insulation Colour | Red, Black, Blue, Yellow, White, Green/Yellow, Grey, Brown |

Third-Party Accreditation | BASEC approved products, tested and certified by BASEC (The British Approvals Service for Cables) |

Standards | EN 50525-2-31 Flame Retardant according to IEC/EN 60332-1-2 |

DIMENSIONS

Feichun PART NO. | Nominal Cross Sectional Area (mm²) | Nominal Thickness of Insulation (mm) | Nominal Overall Diameter (mm) | Nominal Weight (kg/km) |

|---|---|---|---|---|

A2X*0015 | 1.5 | 0.7 | 2.9 | 22 |

A2X*0025 | 2.5 | 0.8 | 3.6 | 32 |

A2X*0040 | 4 | 0.8 | 4.1 | 50 |

A2X*0060 | 6 | 0.8 | 4.7 | 71 |

A2X*010 | 10 | 1.0 | 5.9 | 110 |

A2X*016 | 16 | 1.0 | 6.8 | 164 |

A2X*025 | 25 | 1.2 | 8.4 | 256 |

A2X*035 | 35 | 1.2 | 9.4 | 346 |

A2X*050 | 50 | 1.4 | 11.0 | 473 |

A2X*070 | 70 | 1.4 | 12.7 | 674 |

A2X*095 | 95 | 1.6 | 14.7 | 913 |

A2X*120 | 120 | 1.6 | 16.2 | 1150 |

A2X*150 | 150 | 1.8 | 18.0 | 1416 |

A2X*185 | 185 | 2.0 | 20.0 | 1749 |

A2X*240 | 240 | 2.2 | 23.0 | 2317 |

A2X*300 | 300 | 2.4 | 25.2 | 3049 |

A2X*400 | 400 | 2.6 | 28.4 | 3657 |

A2X*500 | 500 | 2.8 | 31.8 | 4700 |

A2X*630 | 630 | 2.8 | 38.1 | 5890 |

CONDUCTORS

Nominal Cross Sectional Area (mm²) | Minimum No. of Wires in Conductor (Cu) | Minimum No. of Wires in Conductor (Al) | Maximum Resistance of Conductor at 20ºC (ohms/km) |

|---|---|---|---|

1.5 | 7 (Circular) | - | 12.1 |

2.5 | 7 (Circular) | - | 7.41 |

4 | 7 (Circular) | - | 4.61 |

6 | 7 (Circular) | - | 3.08 |

10 | 7 (Circular), 6 (Compacted) | 7 (Circular), 6 (Compacted) | 1.83 |

16 | 7 (Circular), 6 (Compacted) | 7 (Circular), 6 (Compacted) | 1.15 |

25 | 7 (Circular), 6 (Compacted), 6 (Shaped) | 7 (Circular), 6 (Compacted), 6 (Shaped) | 0.727 |

35 | 7 (Circular), 6 (Compacted), 6 (Shaped) | 7 (Circular), 6 (Compacted), 6 (Shaped) | 0.524 |

50 | 19 (Circular), 6 (Compacted), 6 (Shaped) | 19 (Circular), 6 (Compacted), 6 (Shaped) | 0.387 |

70 | 19 (Circular), 12 (Compacted), 12 (Shaped) | 19 (Circular), 12 (Compacted), 12 (Shaped) | 0.268 |

95 | 19 (Circular), 15 (Compacted), 15 (Shaped) | 19 (Circular), 15 (Compacted), 15 (Shaped) | 0.193 |

120 | 37 (Circular), 18 (Compacted), 18 (Shaped) | 37 (Circular), 15 (Compacted), 15 (Shaped) | 0.153 |

150 | 37 (Circular), 18 (Compacted), 18 (Shaped) | 37 (Circular), 15 (Compacted), 15 (Shaped) | 0.124 |

185 | 37 (Circular), 30 (Compacted), 30 (Shaped) | 37 (Circular), 30 (Compacted), 30 (Shaped) | 0.0991 |

240 | 37 (Circular), 34 (Compacted), 34 (Shaped) | 37 (Circular), 30 (Compacted), 30 (Shaped) | 0.0754 |

300 | 61 (Circular), 34 (Compacted), 34 (Shaped) | 61 (Circular), 30 (Compacted), 30 (Shaped) | 0.0601 |

400 | 61 (Circular), 53 (Compacted), 53 (Shaped) | 61 (Circular), 53 (Compacted), 53 (Shaped) | 0.047 |

500 | 61 (Circular), 53 (Compacted), 53 (Shaped) | 61 (Circular), 53 (Compacted), 53 (Shaped) | 0.0366 |

630 | 91 (Circular), 53 (Compacted), 53 (Shaped) | 91 (Circular), 53 (Compacted), 53 (Shaped) | 0.0283 |

Introduction:

Enter the 6491X / H07V-R / H07V-U EN 50525-2-31 cable—a versatile single-core wire designed for demanding applications. This cable, often referred to simply as 6491X cable, embodies the fusion of robust engineering and practical utility, adhering to the stringent EN 50525-2-31 standard. But what makes this cable stand out in a market flooded with options?

At its core, the 6491X H07V-R/H07V-U cable is engineered for power and lighting circuits, building wiring, and internal appliance connections. It's not just a wire; it's a lifeline that operates in semi-flush exposed conduits, embedded conduits, and closed installation ducts. Imagine it as the backbone of your electrical setup, flexible enough to bend around corners yet durable to withstand environmental stresses.

Why Choose This Cable Over Alternatives?

The 6491X / H07V-R / H07V-U EN 50525-2-31 cable shines through its blend of performance, cost-effectiveness, and versatility. First, its class 2 stranded copper conductor offers superior conductivity compared to aluminum alternatives, reducing energy losses and heat generation. Copper's malleability allows for easier installation in convoluted paths, unlike stiffer solid-core options.

PVC insulation provides excellent dielectric strength, preventing short circuits, and its flame-retardant properties (per IEC 60332-1-2) enhance safety in fire-prone areas. Unlike more expensive halogen-free cables, this one balances affordability with reliability, making it ideal for budget-conscious projects without skimping on standards.

Advantages extend to mechanical resilience. The minimum bending radius accommodates tight installations, reducing the need for additional fittings. Its wide temperature range (-15°C to +70°C) outperforms cables limited to milder conditions, suiting global applications from arctic rigs to tropical factories.

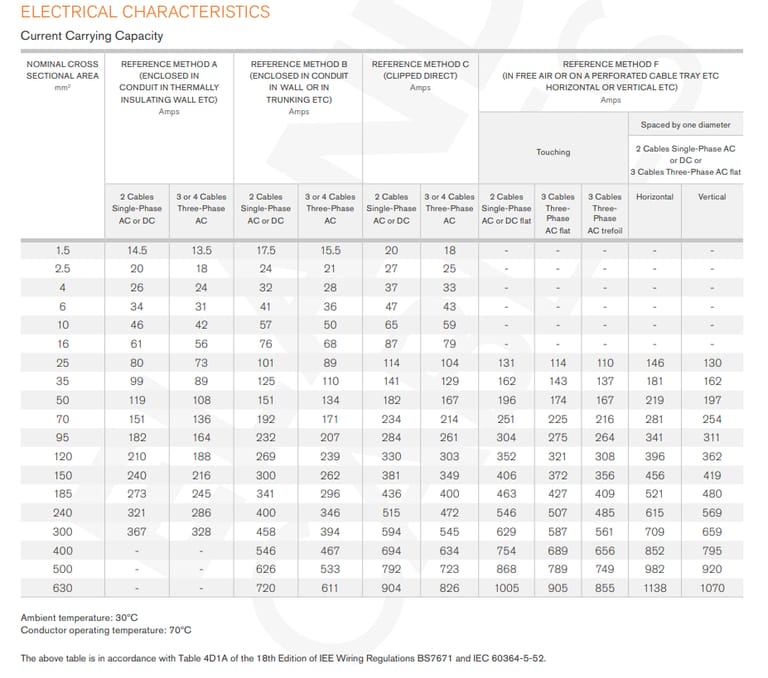

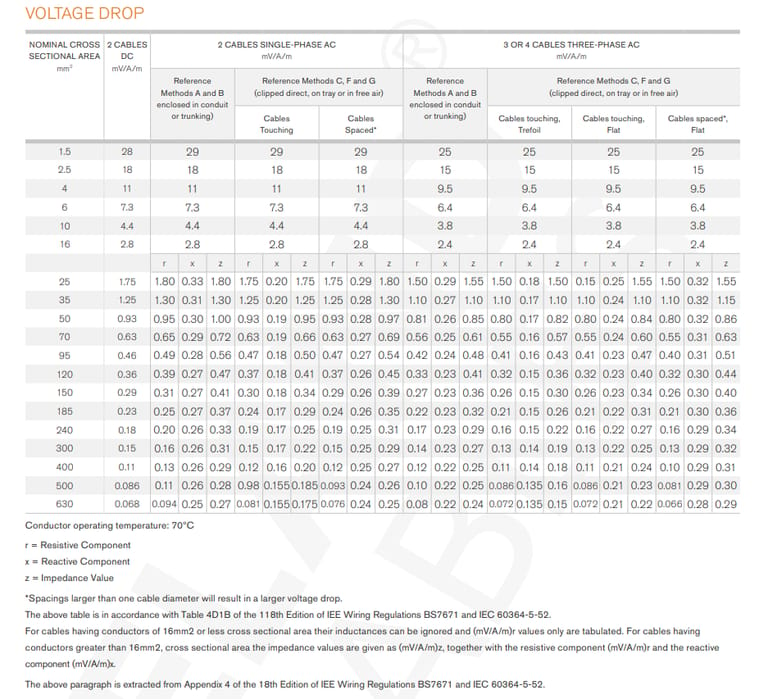

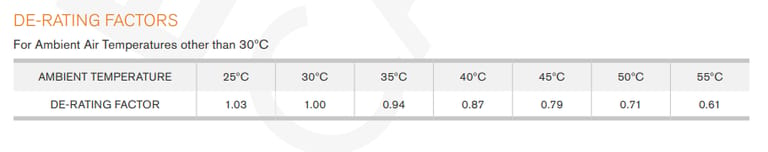

Electrically, high current-carrying capacities—up to 720A for 630mm² in clipped direct methods—support heavy loads, while low voltage drops ensure efficient power delivery over distances. De-rating factors allow precise adjustments, preventing overloads.

Compared to multi-core cables, this single-core design simplifies wiring in conduits, cutting labor costs. BASEC certification adds peace of mind, assuring compliance and longevity. Environmentally, copper is recyclable, aligning with sustainable practices.

In essence, the 6491X cable's advantages lie in its optimized design: flexible yet strong, efficient yet economical, safe yet simple. It's a testament to how specific terminology like H07V-R (stranded) versus H07V-U (solid) empowers informed choices.

Usage Scenarios: From Homes to Heavy Industry

The 6491X / H07V-R / H07V-U EN 50525-2-31 cable thrives in myriad scenarios, leveraging its specs for optimal performance. In residential building wiring, it's perfect for lighting circuits, where 1.5mm² to 6mm² sizes handle switches and outlets in embedded conduits. Its color-coded PVC insulation streamlines connections, ensuring code compliance.

For commercial power circuits, larger cross-sections (16mm²+) power HVAC systems or elevators in closed ducts. The stranded conductor's flexibility aids in semi-flush exposed setups, common in offices.

In appliances, it's used internally for wiring motors or heaters, where the 450/750V rating and +70°C tolerance withstand operational heat. Industrial applications include machinery in factories, with flame-retardant properties safeguarding against sparks.

Renewable energy setups, like solar inverters, benefit from its low resistance, minimizing losses in DC circuits. In transportation, it's wired in vehicles or rail systems, enduring vibrations thanks to class 2 stranding.

Globally, it's deployed in data centers for reliable power distribution, where voltage drop calculations ensure uptime. In harsh environments, de-rating factors adjust for extreme temperatures.

These scenarios highlight the cable's adaptability, always prioritizing safety via EN 50525-2-31 adherence.

Conclusion:

The 6491X / H07V-R / H07V-U EN 50525-2-31 cable exemplifies engineering excellence, from its class 2 stranded copper conductor and PVC insulation to its impressive electrical specs. Its advantages—flexibility, safety, and efficiency—make it indispensable across usage scenarios, as seen in South Africa's Kathu Solar Park. As electrical demands evolve, this cable remains a reliable foundation, powering tomorrow's innovations with timeless reliability.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430