Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Type 210 1.1/1.1KV Mining Cable AS/NZS 1802

Type 210 1.1/1.1kV Mining Power Flexible Feeder Rubber Cable: Cable used primarily for hand-held boring machines and as a flexible lead to other equipment where heavy-duty service is required

Applications

These cables are mainly used for hand-held boring machines and drills.

Standards

AS/NZS 1802:2003

AS/NZS 1125

AS/NZS 3808

AS/NZS 5000.1

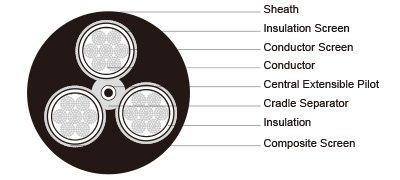

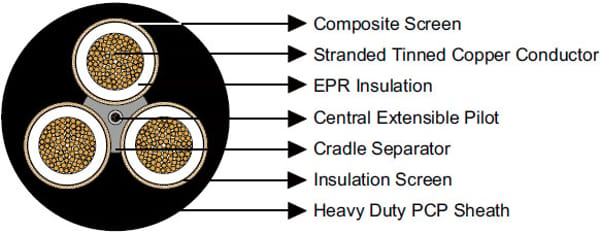

Construction

3×Conductors: Flexible stranded tinned annealed copper conductor.

Conductor Screen:Polyester barrier tape.

Insulation: EPR.

Insulation Screen:Semiconductive tape.

Composite Screen (earth conductor):Tinned annealed copper braiding interwove with polyester yarn.

Cradle Separator: Semiconductive PCP.

1×Central Extensible Pilot:EPR covered flexible stranded tinned copper conductor.

Sheath: Heavy duty PCP sheath.

The AS/NZS 1802 Type 210 1.1/1.1kV Mining Cable from Anhui Feichun Special Cable Co., Ltd. is selected for its superior design and performance, tailored to meet the demanding requirements of mining environments. Below are the key reasons for choosing this cable:

High Conductivity and Flexibility:

The cable features a flexible stranded tinned annealed copper conductor, ensuring excellent electrical conductivity and adaptability to dynamic mining conditions, such as frequent movement and bending, without compromising performance.Robust Insulation for Durability:

The Ethylene Propylene Rubber (EPR) insulation provides outstanding dielectric properties and resilience against mechanical stress, ensuring a long service life even in harsh mining conditions.Enhanced Safety Features:

The cable incorporates a semiconductive elastomer insulation screen and a composite screen of tinned annealed copper braiding interwoven with polyester yarn. This design offers superior electrical shielding and protection, minimizing risks of electrical faults and enhancing safety in mining operations.Central Pilot Core for Operational Efficiency:

The inclusion of a central pilot core, covered in EPR and flexible stranded tinned copper, supports earth continuity and control functions. This is critical for mining equipment like hand-held boring machines and drills, ensuring reliable operation and safety.Thermal and Mechanical Stability:

The semi-conductive thermosetting compound cradle separator enhances the cable’s ability to withstand thermal and mechanical stresses, ensuring consistent performance under extreme conditions typical of mining environments.Compliance with Industry Standards:

The Type 210 cable complies with AS/NZS 1802 and other relevant industry standards, guaranteeing adherence to stringent safety and performance requirements essential for mining applications.

In summary, the AS/NZS 1802 Type 210 1.1/1.1kV Mining Cable is chosen for its combination of flexibility, durability, safety, and compliance, making it an ideal solution for reliable power and control in the rigorous conditions of mining operations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430