Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

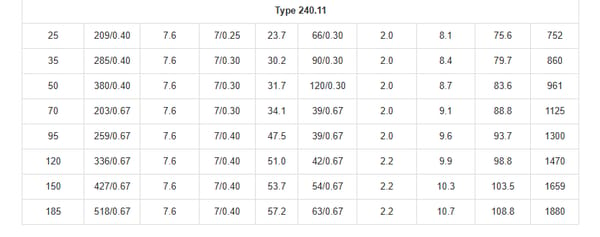

Type 240 1.1 to 11KV Mining Cable AS/NZS 1802

AS/NZS Type 240 1.1 to 11KV Mining Cable: Used as feeder cables for power supply to machinery or longwall supply. Cable contains 3 large pilots and large core screens provide for low resistance earthing.

Applications

These cables are mainly used as feeder cables for power supply to machinery or longwall supply.Cable contains 3 large pilots and large core screens provide for low resistance earthing.

Standards

AS/NZS 1802:2003

AS/NZS 1125

AS/NZS 3808

AS/NZS 5000.1

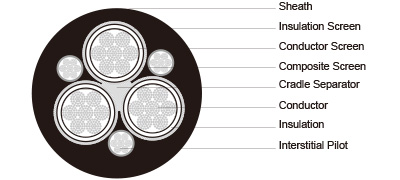

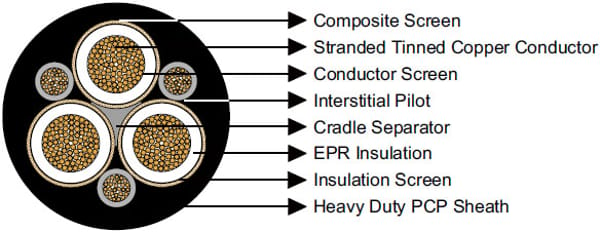

Construction

3×Conductors: Flexible stranded tinned annealed copper conductor.

Conductor Screen: 1.1/1.1kV - polyester barrier tape, 3.3/3.3kV andabove - polyester barrier tape and extruded semiconductive tape.

Insulation: EPR.

Insulation Screen:Semiconductive tape.

Composite Screen (earth conductor):Tinned annealed copper braiding interwove with polyester yarn.

3×Interstitial Pilot:EPR covered flexible stranded tinned copper conductor.

Cradle Separator: Semiconductive PCP.

Sheath: Heavy duty PCP sheath.

The Type 240 mining cable, engineered for 1.1kV to 11kV applications, is a high-performance power cable tailored for demanding mining operations. Its robust construction and advanced technical features make it an optimal solution for underground and surface mining environments where reliability, safety, and efficiency are critical. Below is a detailed analysis of its applications and advantages.

Applications

The Type 240 cable is purpose-built for heavy-duty mining equipment and harsh operational conditions. Its versatility supports a range of critical applications in mining operations, including:

Longwall Shearers and Continuous Miners: Provides consistent and reliable power delivery to longwall shearers and continuous mining equipment, ensuring uninterrupted operation in high-intensity underground mining processes.

Underground Tunnels: Designed for power transmission in confined underground tunnel environments, enabling dependable operation of equipment in restricted spaces with limited maneuverability.

Loaders: Reinforced to withstand significant mechanical stress, the cable ensures durable and efficient power supply for loaders, supporting heavy-duty material handling in mining operations.

Ore Processing Plants: Facilitates efficient power delivery to processing equipment in ore processing facilities, maintaining operational continuity in environments exposed to abrasive and chemically aggressive conditions.

These applications highlight the cable’s adaptability across the mining value chain, from extraction to processing, particularly in high-voltage scenarios requiring robust and reliable power solutions.

Advantages

The Type 240 cable is engineered with a suite of technical features that address the unique challenges of mining environments. The following table summarizes its key advantages and their operational benefits:

Feature | Description and Benefits |

|---|---|

High Durability | Constructed to endure extreme mechanical stress, abrasion, and environmental wear, ensuring prolonged service life and reduced maintenance costs in harsh mining conditions. |

Flexible Construction | Utilizes a flexible rubber sheath, enabling ease of handling and installation in confined or complex layouts, enhancing operational efficiency and reducing installation time. |

Advanced Electromagnetic Shielding | Incorporates advanced shielding to mitigate electromagnetic interference, ensuring stable and uninterrupted power transmission, critical for sensitive mining equipment. |

Chemical Resistance | Engineered to resist degradation from exposure to corrosive chemicals prevalent in mining environments, maintaining structural integrity and performance reliability. |

High-Efficiency Power Transmission | Optimized conductor design minimizes energy losses, delivering efficient power to equipment, reducing operational costs, and enhancing overall system efficiency. |

Safety Compliance | Conforms to AS/NZS standards, ensuring compliance with stringent safety and quality requirements, minimizing risks, and fostering safe mining operations. |

Environmentally Conscious Design | Incorporates eco-friendly materials and manufacturing processes to reduce environmental impact, supporting sustainable mining practices and regulatory compliance. |

The Type 240 1.1 to 11kV mining cable is a robust, high-performance solution tailored for the rigors of underground and surface mining operations. Its applications span critical equipment such as longwall shearers, continuous miners, loaders, and ore processing systems, ensuring reliable power delivery in challenging conditions. The cable’s durability, flexibility, advanced shielding, chemical resistance, and compliance with safety and environmental standards make it a preferred choice for enhancing operational efficiency, safety, and sustainability in mining environments.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430