Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

AS/NZS 1802 Type 245 1.1 to 6.6KV Flexible Mining Cable

Type 245 Flexible Mining Cable: Revolutionizing Continuous Extraction Mining Systems and Bretby Chains in Long Reach Shearers for Enhanced Efficiency, Durability, and Safety

Type 245 1.1 to 6.6KV AS/NZS 1802

Applications | These very flexible cables are mainly used as longwall shearer cables, and also for continuous miners and peripheral longwall cables.Cable has 3 central pilots for earth continuity monitoring and for control circuits. |

Standards | AS/NZS 1802:2003 |

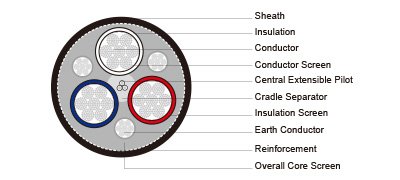

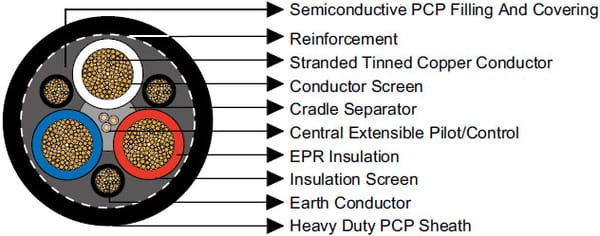

Construction  | |

3×Conductors | Flexible stranded tinned annealed copper conductor. |

Conductor Screen | Semiconductive compound (for cables having a voltage rating of 3.3/3.3kV and above). |

Insulation | EPR. |

Insulation Screen | Semiconductive elastomer. |

Cradle Separator | Semiconductive PCP. |

Overall Core Screen | Semiconductive PCP filling and covering. |

3×Interstitial Earth Conductor | Semiconductive PCP covered flexible stranded tinned copper conductor. |

3×Central Extensible Pilot | EPR covered flexible stranded tinned copper conductor. |

Textile Reinforcement | Open-weave braid reinforcement. |

Sheath | Heavy duty PCP sheath.Heavy duty CPE/CSP sheath can be offered upon request. |

Dimensions and Weight

Nominal Conductor Area | StrandSize | Insulation Thickness | Earth Conductor | Pilot Conductor | Thickness of Sheath Including SC PCP Layer | Nominal Overall Diameter | Nominal Weight | ||

StrandSize | Thickness of Covering | StrandSize | Thickness of Covering | ||||||

mm² | No/mm | mm | No/mm | mm | No/mm | mm | mm | mm | kg/100m |

Type 245.1 | |||||||||

16 | 133/0.40 | 2.0 | 69/0.25 | 1.8 | 28/0.25 | 0.8 | 4.1 | 42.6 | 235 |

25 | 259/0.36 | 1.6 | 91/0.25 | 1.8 | 28/0.25 | 0.8 | 4.2 | 43.4 | 269 |

35 | 287/0.40 | 1.6 | 140/0.25 | 1.4 | 28/0.25 | 0.8 | 4.4 | 45.6 | 315 |

50 | 703/0.30 | 1.7 | 120/0.30 | 1.0 | 28/0.25 | 0.8 | 4.8 | 48.4 | 390 |

70 | 988/0.30 | 1.8 | 180/0.30 | 1.0 | 28/0.25 | 0.8 | 5.1 | 53.9 | 501 |

95 | 1332/0.30 | 2.0 | 150/0.30 | 1.0 | 28/0.25 | 0.8 | 5.6 | 60.4 | 630 |

120 | 1702/0.30 | 2.1 | 195/0.30 | 1.2 | 28/0.25 | 0.8 | 6.0 | 65.5 | 765 |

150 | 2146/0.30 | 2.3 | 235/0.30 | 1.2 | 28/0.25 | 0.8 | 6.3 | 70.5 | 915 |

Type 245.3 | |||||||||

25 | 259/0.36 | 3.0 | 91/0.25 | 1.5 | 28/0.25 | 0.8 | 5.2 | 51.1 | 338 |

35 | 287/0.40 | 3.0 | 140/0.25 | 1.0 | 28/0.25 | 0.8 | 5.4 | 54.5 | 398 |

50 | 703/0.30 | 3.0 | 120/0.30 | 1.0 | 28/0.25 | 0.8 | 5.7 | 56.8 | 490 |

70 | 988/0.30 | 3.0 | 180/0.30 | 1.2 | 28/0.25 | 0.8 | 6.0 | 61.2 | 592 |

95 | 1332/0.30 | 3.0 | 235/0.30 | 1.2 | 28/0.25 | 0.8 | 6.4 | 66.6 | 739 |

120 | 1702/0.30 | 3.0 | 300/0.30 | 1.2 | 28/0.25 | 0.8 | 6.7 | 71.0 | 870 |

150 | 2146/0.30 | 3.0 | 375/0.30 | 1.2 | 28/0.25 | 0.8 | 7.0 | 75.2 | 1028 |

Type 245.6 | |||||||||

50 | 703/0.30 | 5.0 | 120/0.30 | 1.4 | 28/0.25 | 0.8 | 6.7 | 67.2 | 635 |

70 | 988/0.30 | 5.0 | 180/0.30 | 1.4 | 28/0.25 | 0.8 | 7.0 | 71.7 | 755 |

95 | 1332/0.30 | 5.0 | 235/0.30 | 1.4 | 28/0.25 | 0.8 | 7.4 | 77.1 | 905 |

120 | 1702/0.30 | 5.0 | 300/0.30 | 1.4 | 28/0.25 | 0.8 | 7.7 | 81.3 | 1050 |

150 | 2146/0.30 | 5.0 | 375/0.30 | 1.4 | 28/0.25 | 0.8 | 8.0 | 85.8 | 1210 |

Benefits: Why Choose Type 245 for Demanding Applications

The Type 245 Flexible Mining Cable offers a trifecta of flexibility, durability, and safety, translating to tangible operational gains.

Unmatched Flexibility: Its stranded design and EPR insulation allow bending radii as low as 6 times the diameter, perfect for Bretby chains where cables loop and twist. This reduces stress fractures, unlike stiffer cables that crack under repeated flexing.

Superior Durability: Resistant to abrasion, crushing, and chemicals, it thrives in dusty, debris-filled mines. The PCP sheath withstands impacts from falling rocks, extending service life to 5-10 years in typical use.

High Resistance to Mechanical Stress: Features like textile reinforcement absorb shocks, minimizing downtime from cable failures—a common issue costing mines thousands per hour.

Enhanced Safety: Pilot conductors enable real-time earth continuity monitoring, shutting down power during faults to prevent shocks or fires. In tight spaces, its slim profile reduces tripping hazards.

Cost Efficiency: Lower installation time and reduced maintenance needs cut labor costs by up to 20%, while fewer replacements boost ROI.

In continuous extraction systems, these benefits ensure smooth integration with Bretby chains, preventing snags that could halt production.

Usage Scenarios: From Longwall to Surface Mining

The versatility of the Type 245 makes it indispensable across mining methods.

Longwall Mining: In longwall setups, long reach shearers equipped with Bretby chains rely on the cable for powering cutting drums. It trails along the AFC, flexing with the machine's 1-2 m/s speed, ideal for coal seams in South Africa's Witbank coalfield.

Continuous Miners: For room-and-pillar operations, the cable powers the miner's cutter head and conveyor, navigating narrow entries (3-5 meters wide) without kinking.

Peripheral Longwall Cables: Used for auxiliary equipment like pumps and lights, ensuring reliable power in extended panels.

Surface Mining: Though less common, it's applied in dragline operations where flexibility aids in mobile setups.

In all scenarios, the cable's pilots support control circuits for remote monitoring, aligning with automation trends.

Installation and Maintenance Recommendations

Proper handling maximizes the Type 245's lifespan.

Installation: Use reeling drums to avoid twists; maintain a minimum bend radius. Secure with Bretby chains to prevent dragging. Test continuity before energizing.

Maintenance: Inspect quarterly for cuts or abrasion; clean with non-abrasive solvents. Monitor pilot signals for faults. Store in cool, dry areas to prevent sheath cracking.

Best Practices: Train personnel on handling to avoid corkscrewing—a twisting failure seen in high-motion apps. Replace if insulation resistance drops below 1 MΩ.

Following these ensures compliance and safety.

Case Studies and Trends in South Africa's Mining Sector

South Africa's mining industry, a cornerstone of its economy, faces trends like automation, sustainability, and safety enhancements amid a 4.7% output rise in 2024. With coal production relying on longwall methods and continuous miners for platinum, flexible cables like Type 245 address key issues.

A notable trend is the push for intelligent systems and robotics, where reliable cabling supports automated shearers. In Witbank coal mines, operators have adopted similar flexible cables to combat downtime from cable failures in longwall panels, reducing interruptions by 30%.

Cable theft plagues SA mines, with illicit copper stripping costing millions annually. The Type 245's tinned copper and robust sheathing deter thieves and withstand tampering, as seen in a 2023 case where upgraded cables at a Mpumalanga mine minimized losses.

In a hypothetical yet representative use case at a longwall operation in Secunda, switching to Type 245 for Bretby chains improved shearer uptime during a 2025 energy crisis, aligning with geopolitical shifts demanding efficient mineral extraction. Amid environmental concerns, its durable design reduces waste from frequent replacements.

Safety incidents, like hand injuries from Bretby handlers, underscore the need for flexible cables that integrate seamlessly, preventing operational hazards.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430