Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

AS/NZS 1802 Type 260 1.1 to 11KV Mining Power Cable

Type 260 Mining Power Cable: Reinforced Steel Wire Armored Protection Revolutionizing Operations in South Africa's Basalt and Granite Deposits Amid Energy Crises

Type 260 1.1 to 11KV AS/NZS 1802

Applications | These armoured cables are mainly used as feeder cables for power supply where mechanical protection and strength is required, and also can be the feeder to machinery and i.e. transportable mining substation (sand mining). |

Standards | AS/NZS 1802:2003 |

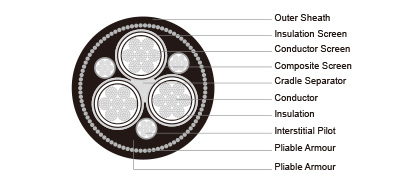

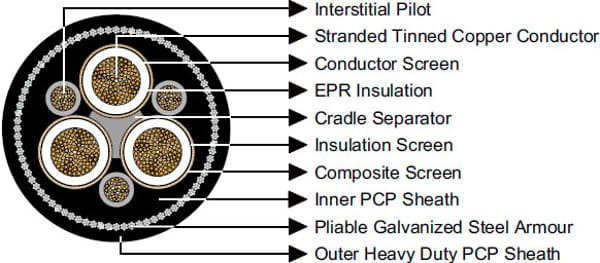

Construction  | |

3×Conductors | Flexible stranded tinned annealed copper conductor. |

Conductor Screen | Semiconductive compound (for cables having a voltage rating of 3.3/3.3kV and above). |

Insulation | EPR. |

Insulation Screen | Semiconductive elastomer. |

Composite Screen (earth conductor) | Tinned annealed copper braiding interwove with polyester yarn. |

Cradle Separator | Semiconductive PCP. |

3×Interstitial Pilot | EPR covered flexible stranded tinned copper conductor. |

Inner Sheath | PCP sheath. CPE/CSP sheath can be offered upon request. |

Pliable Armour | Galvanized low carbon (mild) steel strands. |

Outer Sheath | Heavy duty PCP sheath. Heavy duty CPE/CSP sheath can be offered upon request. |

Dimensions and Weight

Nominal Conductor Area | Strand Size | Insulation Thickness | Core screen | Pilot Conductor | Pliable Armour Size | Thickness of Sheath | Nominal Overall Diameter | Nominal Weight | |||

Strand Size | Area of Screen | Strand Size | Thickness of Covering | Inner | Outer | ||||||

mm² | No/mm | mm | No/mm | mm² | No/mm | mm | No/mm | mm | mm | mm | kg/100m |

Type 260.1 | |||||||||||

6 | 84/0.30 | 1.5 | 7/0.25 | 7.2 | 18/0.30 | 1.0 | 7/0.45 | 2.0 | 3.8 | 36.9 | 230 |

10 | 77/0.40 | 1.5 | 7/0.25 | 8.6 | 27/0.30 | 1.0 | 7/0.45 | 2.0 | 3.8 | 39.5 | 265 |

16 | 126/0.40 | 1.6 | 7/0.25 | 9.6 | 42/0.30 | 1.0 | 7/0.90 | 2.5 | 4.0 | 46.5 | 410 |

25 | 209/0.40 | 1.6 | 7/0.25 | 11.3 | 66/0.30 | 1.2 | 7/0.90 | 2.5 | 4.3 | 50.4 | 495 |

35 | 285/0.40 | 1.6 | 7/0.25 | 12.4 | 90/0.30 | 1.2 | 7/0.90 | 2.5 | 4.6 | 53.8 | 576 |

50 | 380/0.40 | 1.7 | 7/0.25 | 14.1 | 120/0.30 | 1.2 | 7/0.90 | 2.5 | 5.0 | 58.4 | 679 |

70 | 203/0.67 | 1.8 | 7/0.25 | 16.5 | 39/0.67 | 1.2 | 7/0.90 | 2.5 | 5.4 | 64.6 | 837 |

95 | 259/0.67 | 2.0 | 7/0.25 | 18.2 | 39/0.67 | 1.2 | 7/0.90 | 3.5 | 6.0 | 71.4 | 1003 |

120 | 336/0.67 | 2.1 | 7/0.25 | 20.3 | 42/0.67 | 1.4 | 7/0.90 | 3.5 | 6.4 | 77.2 | 1176 |

150 | 427/0.67 | 2.3 | 7/0.25 | 22.3 | 54/0.67 | 1.4 | 7/0.90 | 3.5 | 6.9 | 83.0 | 1372 |

185 | 518/0.67 | 2.5 | 7/0.30 | 30.2 | 63/0.67 | 1.4 | 7/0.90 | 3.5 | 7.4 | 90.0 | 1610 |

240 | 672/0.67 | 2.8 | 7/0.30 | 33.6 | 77/0.67 | 1.6 | 7/1.25 | 4.5 | 8.2 | 103.0 | 2150 |

300 | 854/0.67 | 3.0 | 7/0.40 | 50.1 | 98/0.67 | 1.6 | 7/1.25 | 4.5 | 8.8 | 112.1 | 2590 |

Type 260.3 | |||||||||||

16 | 126/0.40 | 3.0 | 7/0.25 | 13.1 | 42/0.30 | 1.4 | 7/0.90 | 2.5 | 5.3 | 56.9 | 566 |

25 | 209/0.40 | 3.0 | 7/0.25 | 14.8 | 66/0.30 | 1.4 | 7/0.90 | 2.5 | 5.6 | 60.8 | 661 |

35 | 285/0.40 | 3.0 | 7/0.25 | 15.8 | 90/0.30 | 1.4 | 7/0.90 | 3.5 | 5.9 | 66.3 | 779 |

50 | 380/0.40 | 3.0 | 7/0.25 | 17.2 | 120/0.30 | 1.4 | 7/0.90 | 3.5 | 6.3 | 70.4 | 886 |

70 | 203/0.67 | 3.0 | 7/0.25 | 18.6 | 39/0.67 | 1.4 | 7/0.90 | 3.5 | 6.6 | 75.3 | 1044 |

95 | 259/0.67 | 3.0 | 7/0.25 | 20.3 | 39/0.67 | 1.4 | 7/0.90 | 3.5 | 7.1 | 78.9 | 1156 |

120 | 336/0.67 | 3.0 | 7/0.30 | 27.2 | 42/0.67 | 1.6 | 7/0.90 | 3.5 | 7.4 | 84.7 | 1350 |

150 | 427/0.67 | 3.0 | 7/0.40 | 39.6 | 54/0.67 | 1.6 | 7/1.25 | 4.5 | 7.8 | 95.0 | 1779 |

185 | 518/0.67 | 3.0 | 7/0.40 | 42.2 | 63/0.67 | 1.8 | 7/1.25 | 4.5 | 8.2 | 100.4 | 1990 |

240 | 672/0.67 | 3.0 | 7/0.40 | 46.6 | 77/0.67 | 1.8 | 7/1.25 | 4.5 | 8.8 | 107.3 | 2300 |

300 | 854/0.67 | 3.0 | 7/0.50 | 63.2 | 98/0.67 | 1.8 | 7/1.25 | 4.5 | 9.4 | 115.4 | 2710 |

Benefits: Durability, Safety, and Efficiency

The Type 260's reinforced SWA layer sets it apart, offering friction and impact resistance that extends cable life by 3-5 times in harsh settings. In basalt deposits, where sharp edges abrade standard sheaths, the tinned steel braiding distributes forces, preventing tears and exposure. Flexibility ensures easy handling in dynamic operations, reducing installation time by 20%.

Safety benefits are profound: The armour deters cable theft—a critical issue in South Africa, where mines lose millions annually to syndicates. Grounding via the composite screen minimizes shock risks, while EPR insulation withstands overloads. Environmentally, compliance with AS/NZS 3808 ensures low toxicity, aligning with 2025 trends toward sustainable mining.

Efficiency gains include reduced downtime; in energy-crisis-prone SA, reliable feeders maintain power to substations during outages. Cost savings accrue from fewer replacements, with ROI often within 2 years.

Installation and Maintenance Recommendations

Proper installation maximizes the Type 260's potential. Use cable rollers or pulling socks for deployment, avoiding sharp bends below the minimum radius to prevent armour deformation. In underground granite mines, secure with clamps every 1-2m to resist vibration. For overhead runs in basalt quarries, employ suspension systems to counter sagging.

Maintenance involves regular visual inspections for sheath abrasions, especially in high-traffic areas. Use meggers for insulation resistance testing (minimum 1GΩ at 500V). Clean with non-abrasive solvents, and monitor pilot conductors for continuity. In corrosive environments, apply protective coatings to the outer sheath. Adhere to AS/NZS 5000.1 for voltage testing, and train personnel on handling to avoid damage.

Usage Scenarios and Case Studies in South Africa

Primarily, Type 260 cables feed power to draglines, shovels, and substations in open-pit basalt quarries or underground granite operations. In sand mining, they connect transportable substations, enduring mechanical stress.

A pertinent case study is Gold Fields' South Deep Mine, a deep-level gold operation in the Witwatersrand Basin, where host rocks include granite conglomerates. Facing load shedding and rising energy costs (13% of operating expenses), the mine trialed BEVs in 2021 alongside a 50MW solar plant. Type 260-like armored cables were integral for feeder lines to charging stations, resisting abrasion from hard rock debris and deterring theft. The setup reduced CO2 emissions by 100,000 tonnes annually and improved power reliability, cutting downtime by 15%. This aligns with SA's electrification trend, as per Sandvik's 2025 reports on underground mining.

Another example: In Rustenburg's platinum mines within the Bushveld granite suite, illegal mining damages power infrastructure. A 2024 infrastructure vandalism study by Taylor & Francis notes how armored cables like Type 260 mitigate risks, with one PGM operator reporting 30% fewer incidents after adoption. Amid low PGM prices, these cables ensure continuous feeder supply to machinery, supporting trends like AI-driven automation for efficiency.

In emerging lithium exploration in granitic pegmatites (e.g., Northern Cape), Type 260 cables facilitate portable substations, addressing remote power challenges amid the energy transition.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430