Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

AS/NZS 1802 Type 275 1.1/1.1KV Flexible Reeling Mine Cable

AS/NZS Type 275 Flexible Mining Reeling Cable: Revolutionizing High-Speed Reeling Equipment on Shuttle Cars in Underground Mining Operations Under AS/NZS 1802 Standards

Type 275 1.1/1.1KV to AS/NZS 1802

Applications | These cables are mainly used as a flexible feeder for shuttle cars and pump. Earth cores designed to reduce instances of wire breaks during reeling while under tension. |

Standards | AS/NZS 1802:2003 |

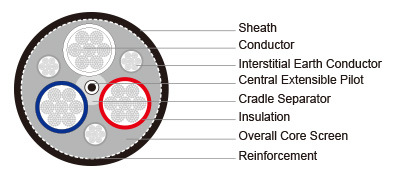

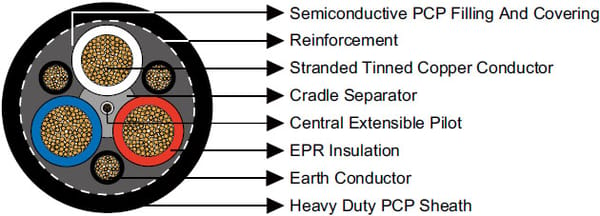

Construction  | |

3×Conductors | Flexible stranded tinned annealed copper conductor. |

Insulation | EPR. |

Cradle Separator | Semiconductive PCP. |

Overall Core Screen | Semiconductive PCP filling and covering. |

3×Interstitial Earth Conductor | Semiconductive PCP covered flexible stranded tinned copper conductor. |

1×Central Extensible Pilot | EPR covered flexible stranded tinned copper conductor. |

Textile Reinforcement | Open-weave braid reinforcement. |

Sheath | Heavy duty PCP sheath. Heavy duty CPE/CSP sheath can be offered upon request. |

Dimensions and Weight

Nominal Conductor Area | Strand Size | Insulation Thickness | Earth Conductor | Pilot Conductor | Thickness of Sheath Including SC PCP Layer | Nominal Overall Diameter | Nominal Weight | ||

Strand Size | Thickness of Covering | Strand Size | Thickness of Covering | ||||||

mm² | No/mm | mm | No/mm | mm | No/mm | mm | mm | mm | kg/100m |

Type 275 |

|

|

|

|

|

|

|

|

|

16 | 126/0.40 | 1.6 | 60/0.30 | 1.0 | 24/0.20 | 0.8 | 3.8 | 30.2 | 145 |

25 | 209/0.40 | 1.6 | 100/0.30 | 1.0 | 24/0.20 | 0.8 | 4.0 | 33.9 | 204 |

35 | 285/0.40 | 1.6 | 140/0.30 | 1.0 | 24/0.20 | 0.8 | 4.3 | 37.9 | 270 |

50 | 380/0.40 | 1.7 | 99/0.40 | 1.0 | 40/0.20 | 0.8 | 4.7 | 41.6 | 333 |

Why Choose Type 275?

The Type 275 shines in high-speed reeling scenarios, where ordinary cables would fail. Its primary benefit is enhanced reeling capability: it can be spooled and unspooled at speeds exceeding 20 meters per minute without degradation, thanks to the extensible pilot and reinforcement braid.

Robustness is another hallmark. The PCP sheath resists abrasion from rocky surfaces, chemicals like oils and acids, and environmental stressors such as moisture and dust—common in underground mines. This durability translates to longer service life, often exceeding 5-7 years with proper care, reducing replacement costs.

Resistance to corkscrewing is a game-changer. In high-tension reeling, cables can twist into a helical shape, causing internal wire breaks. The Type 275's balanced construction and earth cores mitigate this, ensuring consistent performance and fewer downtime incidents.

Compliance with AS/NZS 1802 adds peace of mind, as it mandates testing for tensile strength, elongation, and flame retardance. Operators benefit from improved efficiency: shuttle cars equipped with this cable maintain steady power delivery, boosting haulage rates by up to 20% in optimized setups.

Comparisons with Other Mining Cables

While the Type 275 excels in high-speed applications, it's worth comparing it to peers like Type 409 and Type 441.

Vs. Type 409: Both are mining cables, but Type 409 is geared toward general trailing duties with less emphasis on speed. The Type 275's superior anti-corkscrewing and reeling design make it better for shuttle cars, where rapid cycles demand extra flexibility. Type 409 might suffice for slower equipment but risks higher failure rates in intense scenarios.

Vs. Type 441: Similar in trailing/reeling focus, Type 441 offers good durability but lacks the Type 275's specialized high-speed optimizations. For applications with moderate reeling, Type 441 could be cost-effective; however, in shuttle car ops requiring frequent bends, the Type 275's tensile strength (up to 50 kN) provides an edge, reducing maintenance by 30-40%.

In essence, the Type 275 bridges the gap for demanding, high-velocity tasks.

Applications and Usage Scenarios

Primarily, the Type 275 powers shuttle cars in underground coal or metal mines, where these battery- or cable-powered vehicles transport loads over short distances. It's also used for pumps and other reeling equipment, feeding power flexibly as machinery moves.

In usage, envision a shuttle car in a bord-and-pillar mine: the cable reels out from a fixed point as the car advances to load coal, then retracts during return. This setup is vital in confined spaces, where reliability prevents bottlenecks.

Beyond shuttles, it's adaptable for high-speed drills or loaders in tunneling, handling the "greatest exertion underground" as per industry parlance.

Installation and Maintenance Recommendations

Proper installation maximizes the Type 275's lifespan. Start with site assessment: ensure reeling drums match the cable's bend radius (minimum 6x diameter). Anchor points should use spring-like buffers (e.g., tires) to absorb tension, preventing pillar damage.

During setup, avoid sharp bends or kinks; use cable handlers for deployment. For maintenance, inspect weekly for abrasion or cuts—PCP sheaths are repairable with vulcanized patches. Monitor pilot wires for continuity; faults trigger immediate shutdowns.

Store spares in dry, coiled conditions to prevent corkscrewing. Annual testing per AS/NZS standards, including insulation resistance checks, is advised. In humid mines, apply anti-corrosion sprays on conductors.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430