Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

AS/NZS 2802 Type 412 1.1/1.1KV Mining Trailing Cable

AS/NZS 2802 Type 412 Mining Trailing Cable: Engineered for Safety and Durability in Harsh Mining Environments

Type 412 1.1/1.1KV AS/NZS 2802

Applications | These cables with green/yellow earths and pliable armour for mechanical protection may be used inapplications where damage is likely and armour can reduce cases of costly downtime, suitable installed as feedercables in sand mining operations. |

Standards | AS/NZS 2802:2000 |

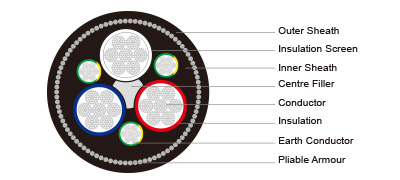

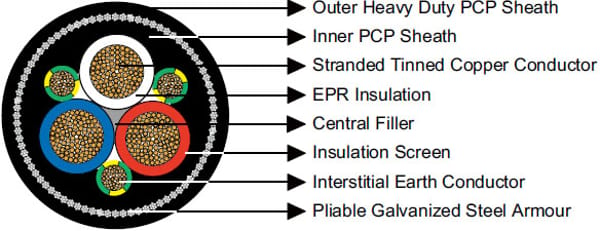

Construction  | |

3×Conductors | Flexible stranded tinned annealed copper conductor. |

Insulation | EPR. |

Insulation Screen | Semiconductive elastomer. |

Filler | Elastomer centre filler. |

3×Interstitial Earth Conductor | EPR covered flexible stranded tinned copper conductor. |

Inner Sheath | PCP sheath.CPE/CSP sheath can be offered upon request. |

Pliable Armour | Galvanized low carbon (mild) steel strands. |

Outer Sheath | Heavy duty PCP sheath. Heavy duty CPE/CSP sheath can be offered upon request. |

Dimensions and Weight

Nominal Conductor Area | Strand Size | Insulation Thickness | Earth Conductor | Pliable Armour Size | Thickness of Sheath | Nominal Overall Diameter | Nominal Weight | ||

Strand Size | Thickness of Covering | Inner | Outer | ||||||

mm² | No/mm | mm | No/mm | mm | No/mm | mm | mm | mm | kg/100m |

Type 412.1 Class2 | |||||||||

16 | 126/0.40 | 1.6 | 81/0.30 | 0.6 | 7/0.90 | 2.5 | 3.8 | 38.3 | 265 |

25 | 209/0.40 | 1.6 | 81/0.30 | 0.6 | 7/0.90 | 2.5 | 3.8 | 38.4 | 294 |

35 | 285/0.40 | 1.6 | 81/0.30 | 0.6 | 7/0.90 | 2.5 | 4.0 | 44.6 | 402 |

50 | 380/0.40 | 1.7 | 120/0.30 | 0.8 | 7/0.90 | 2.5 | 4.4 | 49.2 | 500 |

70 | 203/0.67 | 1.8 | 39/0.67 | 0.8 | 7/0.90 | 2.5 | 4.8 | 55.4 | 655 |

95 | 259/0.67 | 2.0 | 48/0.67 | 0.8 | 7/0.90 | 2.5 | 5.4 | 60.1 | 775 |

120 | 336/0.67 | 2.1 | 60/0.67 | 1.0 | 7/0.90 | 3.5 | 5.8 | 68.1 | 990 |

150 | 427/0.67 | 2.3 | 77/0.67 | 1.0 | 7/0.90 | 3.5 | 6.3 | 73.8 | 1186 |

185 | 518/0.67 | 2.5 | 91/0.67 | 1.0 | 7/0.90 | 3.5 | 6.8 | 80.2 | 1360 |

240 | 672/0.67 | 2.8 | 119/0.67 | 1.2 | 7/0.90 | 3.5 | 7.5 | 88.7 | 1670 |

300 | 854/0.67 | 3.0 | 156/0.67 | 1.2 | 7/1.25 | 4.5 | 8.2 | 100.9 | 2200 |

Benefits of the Type 412 Mining Trailing Cable

The Type 412 cable offers several advantages that make it a preferred choice for mining operations:

Explosion-Proof Design: The EPR insulation and semiconductive screen prevent electrical faults from igniting flammable gases, ensuring compliance with safety standards like AS/NZS 2802:2000.

Superior Mechanical Protection: The pliable steel armor and heavy-duty sheath protect against crushing, abrasion, and impact from heavy machinery, reducing downtime.

High-Strength Insulation: The EPR insulation resists heat, chemicals, and abrasion, ensuring long-term reliability.

Flexibility: The flexible stranded conductors and elastomer filler allow the cable to be maneuvered in confined spaces, such as underground tunnels.

Cost-Effectiveness: Its durability reduces maintenance and replacement costs, offering a strong return on investment.

Installation and Maintenance Recommendations

To maximize the performance and lifespan of the Type 412 Mining Trailing Cable, proper installation and maintenance are critical. Here are key recommendations:

Installation Guidelines

Route Planning: Plan cable routes to avoid sharp bends, abrasive surfaces, and areas with heavy machinery traffic. Use cable rollers or guides to minimize drag and abrasion.

Tension Control: Avoid excessive pulling tension during installation, as this can damage the conductor or insulation. Follow manufacturer guidelines for maximum pulling tension (typically based on conductor size).

Securing the Cable: Use appropriate cable clamps or supports to secure the cable, preventing undue stress on the armor or sheath.

Environmental Protection: Ensure the cable is protected from prolonged exposure to standing water or corrosive chemicals, even though it is designed for harsh environments.

Grounding: Properly connect earth conductors to ensure safe grounding, especially in explosive atmospheres.

Maintenance Practices

Regular Inspections: Inspect cables monthly for signs of wear, such as cuts, abrasions, or exposed conductors. Pay special attention to areas near machinery or high-traffic zones.

Cleaning: Remove dirt, dust, or chemical residues from the outer sheath to prevent degradation. Use non-abrasive cleaning methods.

Testing: Periodically test insulation resistance and continuity to detect potential faults before they cause failures.

Storage: Store spare cables in a dry, cool environment away from direct sunlight to prevent sheath degradation.

Repair or Replace: Replace damaged sections promptly to avoid compromising safety. Avoid temporary repairs in explosive environments.

Usage Scenarios in South African Mining

South Africa’s mining industry, a global leader in gold, platinum, and coal production, relies heavily on robust infrastructure to maintain productivity and safety. The Type 412 Mining Trailing Cable is tailored for several key applications:

Underground Gold and Platinum Mines

In South Africa’s deep-level gold mines, such as those in Gauteng, or platinum mines in the Bushveld Complex, the Type 412 cable powers critical equipment like drills and ventilation systems. Its explosion-proof design is essential in these methane-prone environments, where a single spark could trigger disaster. For example, in a 2024 incident at a Gauteng gold mine, a cable failure led to a temporary shutdown, highlighting the need for reliable cables like the Type 412 to minimize downtime.

Surface Coal Mining in Mpumalanga

Open-pit coal mines in Mpumalanga, such as those operated by major firms like Sasol, rely on the Type 412 cable to power draglines and conveyors. The cable’s pliable armor protects against abrasion from rocky terrain, ensuring consistent power delivery. A 2025 case study from a Mpumalanga mine demonstrated that switching to Type 412 cables reduced maintenance costs by 15% due to fewer cable failures.

Sand Mining Operations

In coastal sand mining operations, such as those extracting titanium minerals in KwaZulu-Natal, the Type 412 cable serves as a feeder cable for heavy machinery. Its flexibility and robust sheathing make it ideal for dynamic environments where cables are frequently moved. A recent project in Richards Bay reported a 20% reduction in downtime after adopting Type 412 cables for their durability.

Heavy Machinery Power Supply

Across South African mines, the Type 412 cable powers high-demand equipment like excavators and haul trucks. Its ability to withstand mechanical stress ensures uninterrupted operation, critical in high-output mines where downtime can cost millions of rands per hour.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430