Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

AS/NZS 2802 Type 440 1.1 to 22KV Mining Cable

Type 440 Mining Cable Variants from 1.1kV to 22kV Are Essential for Safe, Reliable, and Efficient Power in Modern Mining and Heavy Industry

AS/NZS 2802 Type 440 1.1 to 22 KV

Applications | These cables are mainly used as flexible feeder trailing cables for power supply to machinery and equipment, include 3 large pilots and a centra lsemiconductive cradle for support and protection of power cores |

Standards | AS/NZS 2802:2000 |

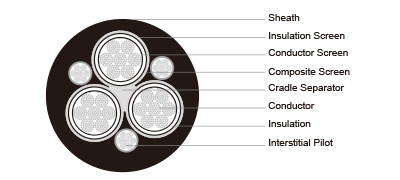

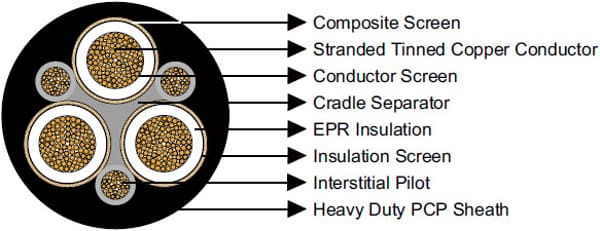

Construction  | |

3×Conductors | Flexible stranded tinned annealed copper conductor. |

Conductor Screen | 1.1/1.1kv - polyester barrier tape, 3.3/3.3kv andabove - polyester barrier tape and extruded semiconductive tape. |

Insulation | EPR. |

Insulation Screen | Semiconductive elastomer. |

Composite Screen (earth conductor) | Tinned annealed copper braiding interwove with polyester yarn. |

Cradle Separator | Semiconductive PCP. |

3×Interstitial Pilot | EPR covered flexible stranded tinned copper conductor. |

Sheath | Heavy duty PCP sheath. Heavy duty CPE/CSP sheath can be offered upon request. |

The Type 440 series spans from low-voltage (1.1kV) to very high-voltage (22kV), with variants optimized for specific operational needs:

Type 440.1 (Class 2) – Low voltage, high performance

Type 440.3 (Class 2) – Medium voltage, enhanced durability

Type 440.6 (Class 2) – High voltage, maximum efficiency

Type 440.11 (Class 2) – Very high voltage, extreme environments

Type 440.22 (Class 2) – Ultra-high voltage, specialized applications

The Variants of Type 440 Mining Cables

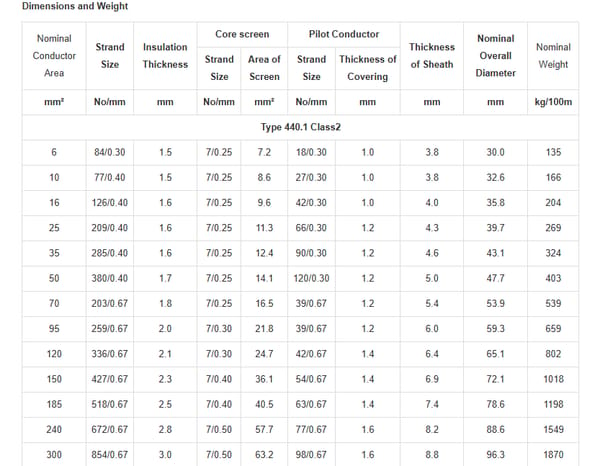

1. Type 440.1 (Class 2) – Low Voltage (1.1 to 3.3kV)

Designed for small-scale machinery and auxiliary systems: pumps, lighting, fans, and control circuits. Its flexibility makes it easy to install in narrow tunnels and confined shafts.

Key Features:

Nominal conductor area: 6–300 mm²

Insulation thickness: 1.5–3.0 mm

Nominal overall diameter: ~30–96 mm

Weight: 135–1870 kg/100m

South African Case Use:

In underground gold mines around Carletonville, Type 440.1 is commonly deployed to power pumping systems that prevent water ingress—an ongoing safety issue in deep-level mining.

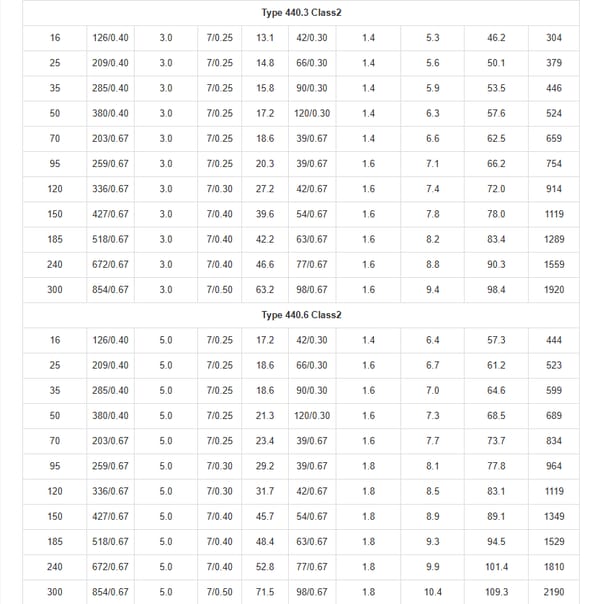

2. Type 440.3 (Class 2) – Medium Voltage (3.3 to 6.6kV)

Used in conveyor systems, drilling rigs, and medium-duty equipment, this cable withstands higher loads while offering abrasion resistance.

Key Features:

Nominal conductor area: 16–300 mm²

Insulation thickness: 3.0 mm

Nominal overall diameter: ~46–98 mm

Weight: 304–1920 kg/100m

Case Study:

A platinum mine near Rustenburg upgraded its conveyor systems in 2024 to reduce downtime. Engineers replaced older cables with Type 440.3, citing reduced mechanical failures and improved durability under constant flexing.

3. Type 440.6 (Class 2) – High Voltage (6.6 to 11kV)

For heavy-duty machinery like draglines, shovels, and large-scale pumps, Type 440.6 ensures efficient long-distance power transfer.

Key Features:

Nominal conductor area: 16–300 mm²

Insulation thickness: 5.0 mm

Nominal overall diameter: ~57–109 mm

Weight: 444–2190 kg/100m

Case Study:

At an open-cast coal mine in Mpumalanga, Type 440.6 cables power draglines used for large-scale excavation. The added sheath thickness provides excellent protection against impact and abrasion from heavy equipment.

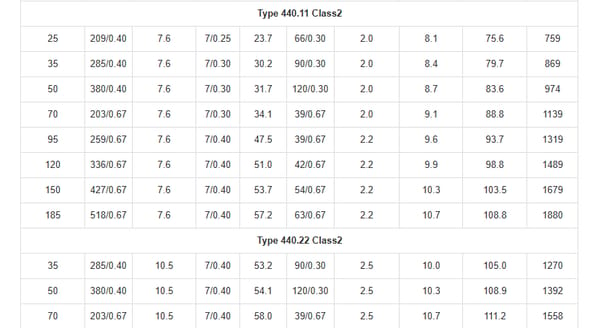

4. Type 440.11 (Class 2) – Very High Voltage (11 to 22kV)

Built for extreme environments requiring longwall systems, deep pumps, and high-capacity haulage machinery.

Key Features:

Nominal conductor area: 25–185 mm²

Insulation thickness: 7.6 mm

Nominal overall diameter: ~75–108 mm

Weight: 759–1880 kg/100m

Use Case in South Africa:

In 2023, a deep-level mine in the Witwatersrand Basin implemented Type 440.11 cables for longwall coal mining. The cables’ advanced insulation resisted electrical surges caused by sudden load fluctuations.

5. Type 440.22 (Class 2) – Ultra-High Voltage (Up to 33kV)

This is the flagship variant, used in specialized, ultra-high power applications such as main feeders and high-capacity machinery.

Key Features:

Nominal conductor area: 35–70 mm²

Insulation thickness: 10.5 mm

Nominal overall diameter: ~105–111 mm

Weight: 1270–1558 kg/100m

Benefits of Type 440 Mining Cables

Durability Under Stress – Resistant to bending, crushing, and impact.

Environmental Resistance – Sheaths withstand oil, flame, chemicals, and abrasion.

Safety – Compliance with AS/NZS standards ensures safety in hazardous settings.

Flexibility – Easy routing in confined underground spaces.

Long Service Life – Designed to reduce failures and maintenance costs.

Installation and Maintenance Recommendations

Pre-installation checks: Verify voltage ratings and sheath integrity.

Bending radius compliance: Avoid sharp bends to prevent conductor fatigue.

Strain relief: Ensure proper clamping to reduce mechanical stress.

Regular inspections: Look for sheath wear, conductor exposure, or insulation damage.

Cleaning protocols: Remove dust, oil, and chemicals from sheath surfaces.

Splicing guidelines: Use manufacturer-approved kits; improper splicing risks electrical faults.

FAQs

Q1: Why not use standard industrial cables in mining?

Standard cables lack the mechanical strength, flexibility, and chemical resistance required in mining. Type 440 cables are purpose-built.

Q2: Can Type 440 cables be reused after relocation?

Yes, if inspected and tested. However, cables showing sheath damage or conductor stress should be retired.

Q3: Are Type 440 cables flame retardant?

Yes, the heavy-duty PCP sheath provides flame resistance, with optional CSP/CPE for higher fire safety.

Q4: What are pilot conductors used for?

They enable monitoring, fault detection, and communication between equipment and control systems.

Q5: Do South African mines import or locally source Type 440 cables?

Both. Many cables are imported from international manufacturers, but local suppliers stock them to meet mining demand quickly.

The Type 440 Mining Cable series—spanning from 1.1kV to 22kV—is a cornerstone of modern mining and heavy industry. Each variant (440.1, 440.3, 440.6, 440.11, and 440.22) is tailored to specific applications, ensuring reliable power delivery in some of the harshest environments on Earth.

For South Africa’s mining sector, where operational efficiency and safety are non-negotiable, these cables offer a proven, standards-compliant solution. Whether powering underground pumps, conveyor belts, or ultra-high voltage smelters, Type 440 cables ensure that electricity flows where it is needed most—safely, efficiently, and reliably.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430