Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

AS/NZS 2802 Type 441 (class 1) 3.3 to 22KV Reeling and Trailing Mining Cables

Comprehensive Guide to Type 441(class 1) Reeling and Trailing Mining Cables under AS/NZS 2802:2000 with Central Semiconductive Cradle for Reliable Power in South African Mining and Heavy Industry

Type 441 (class 1) 3.3 to 22KV to AS/NZS 2802

Applications | Type 441 Class 1 series cable has lower insulation and sheath radials than Class 2 cables, designed for many uses, suitable for trailing and also suitable for reeling applications, have one central pilot and a semiconductive cradle supportingand protecting the power cores, which makes these cables less likely to be damaged from crushing and squashing. |

Standards | AS/NZS 2802:2000 |

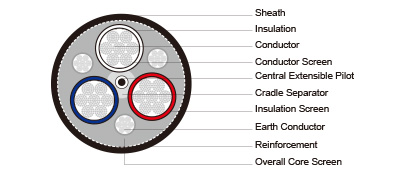

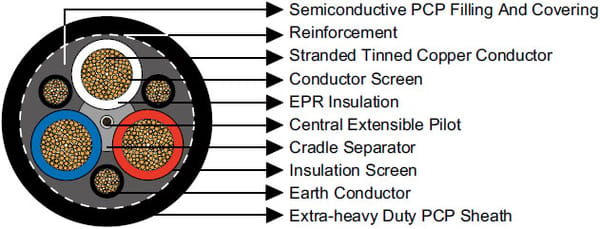

Construction  | |

3×Conductors | Flexible stranded tinned annealed copper conductor. |

Conductor Screen | Semiconductive compound (for cables having a voltage rating of 3.3/3.3kV and above). |

Insulation | EPR. |

Insulation Screen | Semiconductive elastomer. |

Cradle Separator | Semiconductive PCP. |

Overall Core Screen | Semiconductive PCP filling and covering. |

3×Interstitial Earth Conductor | Semiconductive PCP covered flexible stranded tinned copper conductor. |

1×Central Extensible Pilot | EPR covered flexible stranded tinned copper conductor. |

TextileReinforcement | Open-weave braid reinforcement. |

Sheath | Heavy duty PCP sheath. Heavy duty CPE/CSP sheath can be offered upon request. |

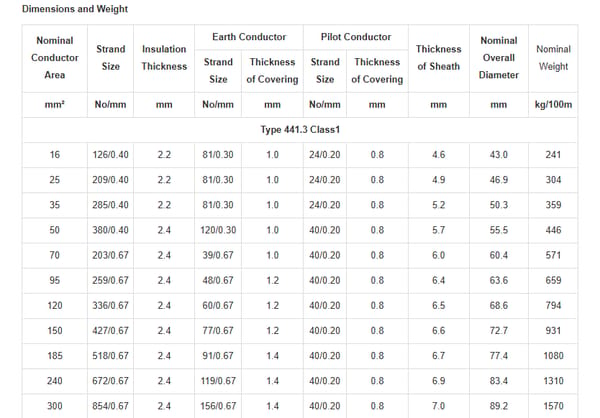

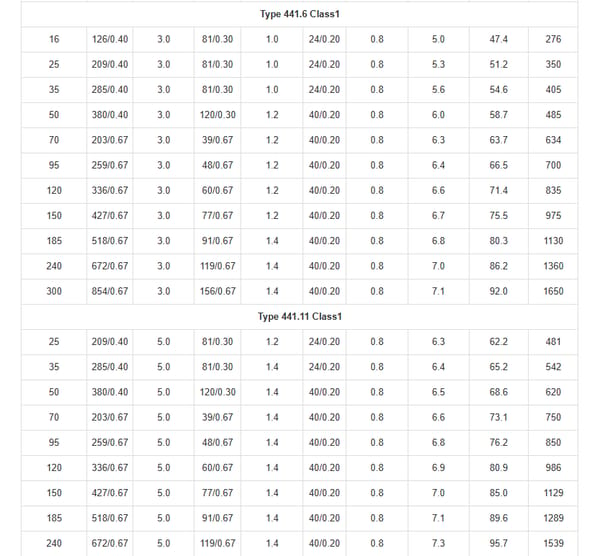

Electrical Ratings

Voltage: 3.3kV up to 22kV (Type 441.22 is rated at 22kV).

Temperature Range: Typically –25°C to +90°C.

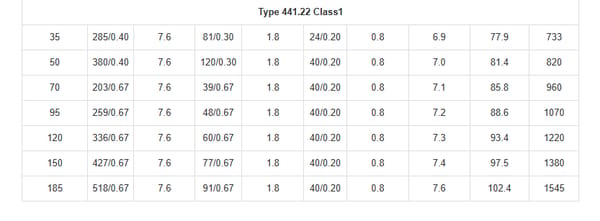

Current-Carrying Capacity: Varies with conductor size (35mm² to 300mm²).

Advantages of Type 441 (class 1) Reeling and Trailing Mining Cables

High Voltage Capability

Delivers 22kV safely, suitable for draglines, shovels, and large electric loaders.

Mechanical Protection

Central cradle + PCP sheath = resistance to crushing, impact, and abrasion.

Electrical Stability

Semiconductive screening reduces risk of partial discharge and faults.

Flexibility for Reeling and Trailing

Designed to withstand constant winding/unwinding on reels.

Safety Compliance

Meets AS/NZS 2802:2000, ensuring reliability in hazardous mine sites.

Longevity and Cost Efficiency

Durable materials reduce frequency of replacement, lowering lifetime cost.

Applications in Mining and Industry

1. Underground Mining

Supplying power to drilling rigs, shuttle cars, and continuous miners.

Flexibility allows movement through narrow tunnels.

2. Open-Cast Mining

Used in reeling systems for draglines, electric shovels, and stackers.

Withstands UV exposure and mechanical stress.

3. Power Feeder Cables

Acts as a mine power distribution backbone, linking substations to equipment.

4. Heavy Industry

Steel plants, cement works, and ports use Type 441 (class 1) for mobile cranes and conveyors.

Installation Recommendations

Bend Radius: Minimum 6 × overall diameter to prevent insulation stress.

Tension: Avoid exceeding 50 N/mm² on conductor cross-sectional area.

Reeling Drums: Use correctly sized cable reels with tension control.

Clamping & Routing: Use proper cleats and trays to prevent crushing.

Maintenance and Safety Practices

Visual Inspections

Check for sheath cuts, flattening, or abrasion.

Electrical Testing

Perform insulation resistance and partial discharge testing.

Cleaning

Remove mud, oil, and coal dust to reduce sheath degradation.

Splicing and Repairs

Must follow standards; improper splicing increases fire and shock hazards.

Cable Rotation

Rotate cables periodically to distribute wear evenly.

Frequently Asked Questions (FAQ)

Q1. What makes Type 441(class 1) different from other mining cables?

The central semiconductive cradle provides structural support, preventing crushing damage and ensuring longer service life.

Q2. Can it be used in both underground and surface mining?

Yes. The robust sheath and flexibility make it suitable for underground tunneling and open-pit reeling applications.

Q3. How does it compare to Class 2 cables?

Class 1 (441.22) has thinner insulation and sheath, making it lighter and more flexible, while Class 2 offers thicker protection for extreme mechanical hazards.

Q4. What is the maximum voltage rating?

The Type 441(class 1) is designed for 22kV operations.

Q5. Are these cables accepted in South Africa?

Yes. Although based on AS/NZS standards, they meet equivalent safety and performance requirements for South African mines and can be certified under NRCS where applicable.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430