Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

AS/NZS 2802 Type 441 (Class 2) 1.1/1.1kV Composite Braided Shielded Mining Cable

Comprehensive Guide to Type 441 (Class 2) 1.1/1.1kV Composite Braided Shielded Mining Cable for Heavy-Duty Mining Machines in South Africa and Australia

Type 441 (class 2) 1.1/1.1KV to AS/NZS 2802

Applications | These Class 2 cables are designed for many uses, suitable for trailing and also suitable for reeling applications, have one central pilot and a semiconductive cradle supportingand protecting the power cores, which makes these cables less likely to be damaged from crushing and squashing |

Standards | AS/NZS 2802:2000 |

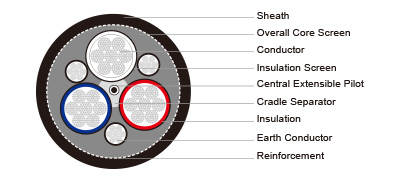

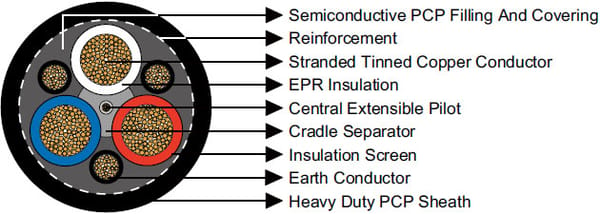

Construction  | |

3×Conductors | Flexible stranded tinned annealed copper conductor. |

Insulation | EPR. |

Insulation Screen | Semiconductive elastomer. |

Cradle Separator | Semiconductive PCP. |

Overall Core Screen | Semiconductive PCP filling and covering. |

3×Interstitial Earth Conductor | Semiconductive PCP covered flexible stranded tinned copper conductor. |

1×Central Extensible Pilot | EPR covered flexible stranded tinned copper conductor. |

TextileReinforcement | Open-weave braid reinforcement. |

Sheath | Heavy duty PCP sheath. Heavy duty CPE/CSP sheath can be offered upon request. |

Dimensions and Weight

Nominal Conductor Area | Strand Size | Insulation Thickness | Earth Conductor | Pilot Conductor | Thickness of Sheath | Nominal Overall Diameter | Nominal Weight | ||

Strand Size | Thickness of Covering | Strand Size | Thickness of Covering | ||||||

mm² | No/mm | mm | No/mm | mm | No/mm | mm | mm | mm | kg/100m |

Type 441.1 Class2 | |||||||||

6 | 84/0.30 | 1.5 | 33/0.30 | 0.8 | 24/0.20 | 0.8 | 3.8 | 28.5 | 111 |

10 | 77/0.40 | 1.5 | 51/0.30 | 0.8 | 24/0.20 | 0.8 | 3.8 | 31.1 | 136 |

16 | 126/0.40 | 1.6 | 81/0.30 | 1.0 | 24/0.20 | 0.8 | 3.9 | 34.1 | 176 |

25 | 209/0.40 | 1.6 | 81/0.30 | 1.0 | 24/0.20 | 0.8 | 4.2 | 37.9 | 231 |

35 | 285/0.40 | 1.6 | 81/0.30 | 1.0 | 24/0.20 | 0.8 | 4.4 | 41.2 | 274 |

50 | 380/0.40 | 1.7 | 120/0.30 | 1.0 | 40/0.20 | 0.8 | 4.9 | 45.9 | 349 |

70 | 203/0.67 | 1.8 | 39/0.67 | 1.0 | 40/0.20 | 0.8 | 5.3 | 52.2 | 481 |

95 | 259/0.67 | 2.0 | 48/0.67 | 1.0 | 40/0.20 | 0.8 | 5.8 | 56.7 | 579 |

120 | 336/0.67 | 2.1 | 60/0.67 | 1.0 | 40/0.20 | 0.8 | 6.3 | 62.7 | 724 |

150 | 427/0.67 | 2.3 | 77/0.67 | 1.2 | 40/0.20 | 0.8 | 6.7 | 68.3 | 881 |

185 | 518/0.67 | 2.5 | 91/0.67 | 1.2 | 40/0.20 | 0.8 | 7.3 | 74.9 | 1049 |

240 | 672/0.67 | 2.8 | 119/0.67 | 1.2 | 40/0.20 | 0.8 | 8.0 | 83.3 | 1329 |

300 | 854/0.67 | 3.0 | 156/0.67 | 1.4 | 40/0.20 | 0.8 | 8.7 | 91.2 | 1629 |

What Is the Type 441 (Class 2) Mining Cable?

The Type 441 mining cable is a low-voltage flexible power cable rated at 1.1/1.1kV. It is specifically engineered for:

Trailing applications (dragged behind mobile equipment).

Reeling applications (wound and unwound repeatedly on cable reels).

High-stress environments where crushing, abrasion, and electrical interference are common.

A unique feature is its central pilot conductor and semiconductive cradle separator, which help protect the power cores from crushing and enhance overall reliability.

Key Standards

AS/NZS 2802:2000 – Mining cables

AS/NZS 1125 – Conductors in insulated cables

AS/NZS 3808 – Insulating and sheathing materials

AS/NZS 5000.1 – General low-voltage cable requirements

These ensure compliance with safety, fire resistance, and mechanical performance criteria demanded in mining.

Benefits of Type 441 (Class 2) Cables

1. Durability Under Stress

The semiconductive cradle and reinforced sheath resist crushing, bending, and abrasion. This is vital in underground South African gold mines, where cables often get trapped between rock walls and machinery.

2. Electromagnetic Interference (EMI) Protection

The composite braided shielding maintains signal integrity, crucial for automated mining systems where sensors and controls rely on clean signals.

3. Safety and Reliability

High-grade EPR insulation and robust sheath materials ensure flame retardancy, oil resistance, and thermal stability.

4. Versatility

Suitable for trailing, reeling, and flexible power supply, Type 441 is used across drilling rigs, conveyor systems, shuttle cars, and haulage equipment.

Use Cases in Mining and Heavy Industry

Case Study 1: South Africa’s Platinum Belt

In Rustenburg, platinum mines employ Type 441 cables for powering large drilling rigs. Their resistance to crushing prevents frequent cable replacements in narrow shaft tunnels, reducing maintenance downtime.

Case Study 2: Australian Coal Mines

In Queensland’s coal mines, reeling applications require cables that endure thousands of winding cycles. Type 441’s open-weave reinforcement prevents internal stress cracking, ensuring consistent performance.

Case Study 3: Conveyor Systems in Mpumalanga

South African coal transport relies on kilometers of conveyors. Type 441 cables withstand dust, moisture, and mechanical vibration, providing continuous power without signal disruption.

Why Choose Type 441 for Your Operation?

Reliability: Proven in harsh Australian and South African mines.

Standard Compliance: Meets AS/NZS and international benchmarks.

Operational Flexibility: Suitable for reeling, trailing, and flexible equipment.

Reduced Downtime: Withstands crushing, squashing, and mechanical wear.

Future-Ready: Supports electrified and automated mining systems.

The Type 441 (Class 2) 1.1/1.1kV composite braided shielded mining cable is not just a power delivery medium—it is a strategic asset in modern mining. By ensuring uninterrupted power, shielding against interference, and providing mechanical resilience, it supports productivity, safety, and sustainability.

For South African mining companies under pressure from rising energy costs, labor challenges, and regulatory compliance, adopting reliable cables like Type 441 ensures reduced downtime, improved worker safety, and better operational efficiency.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430