Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

AS/NZS 2802 Type 450 3.3 to 33KV Mining Trailing Cable

Type 450 Mining Trailing Cable Series: Designed to Meet the Demanding Requirements of Mining Operations, offering Unmatched Durability, Safety, and Versatility.

Type 450 3.3 to 33KV to AS/NZS 2802

Applications | These cables are suitable for supply of power to a wide range of applications, from dragline cable to slow reeling applications, where copper screened cable is required but light weight and smaller dimensions are also desired. |

Standards | AS/NZS 2802:2000 |

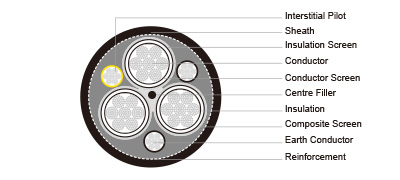

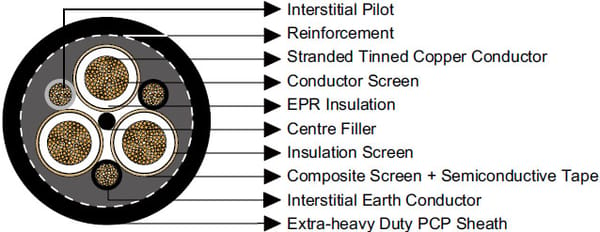

Construction  | |

3×Conductors | Flexible stranded tinned annealed copper conductor. |

Conductor Screen | Semiconductive compound (for cables having a voltage rating of 3.3/3.3kV and above). |

Insulation | EPR. |

Insulation Screen | Semiconductive elastomer. |

Composite Screen | Tinned annealed copper braiding interwove with polyester yarn, covered with semiconductive tape. |

Filler | Elastomer centre filler. |

2×Interstitial Earth Conductor | CSP covered flexible stranded tinned copper conductor. |

1×Interstitial Pilot | EPR covered flexible stranded tinned copper conductor. |

TextileReinforcement | Open-weave braid reinforcement. |

Sheath | Heavy duty PCP sheath. Heavy duty CPE/CSP sheath can be offered upon request. |

Benefits of Type 450 Mining Trailing Cables

The Type 450 series is a cornerstone of modern mining operations due to its exceptional performance characteristics:

Durability: High-grade materials resist wear, mechanical stress, and environmental hazards, ensuring long-term reliability.

Safety: Compliance with AS/NZS standards minimizes risks in hazardous mining environments.

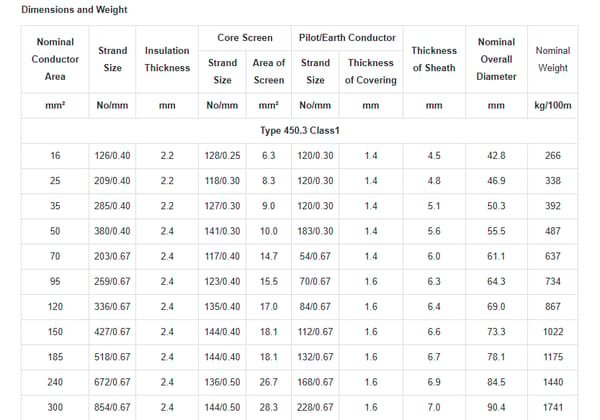

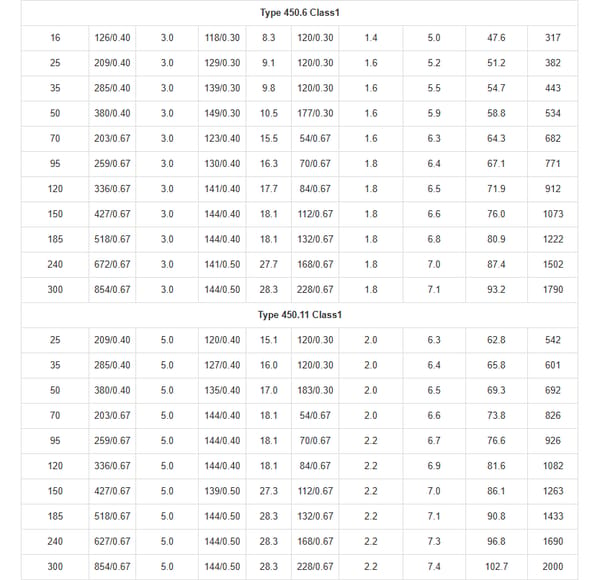

Versatility: The range of voltage ratings (3.3kV–33kV) and conductor sizes (16–300 mm²) caters to diverse applications.

Lightweight Design: Despite robust construction, the cables are optimized for portability in slow reeling applications.

Efficiency: Advanced insulation and screening reduce energy loss, enhancing operational efficiency.

Applications in South Africa’s Mining Industry

South Africa’s mining sector, a backbone of the economy, relies heavily on reliable power solutions. The Type 450 series is tailored for key applications:

Underground Mining: In coal and platinum mines, Type 450.3 and Type 450.6 power lighting and ventilation systems, ensuring worker safety.

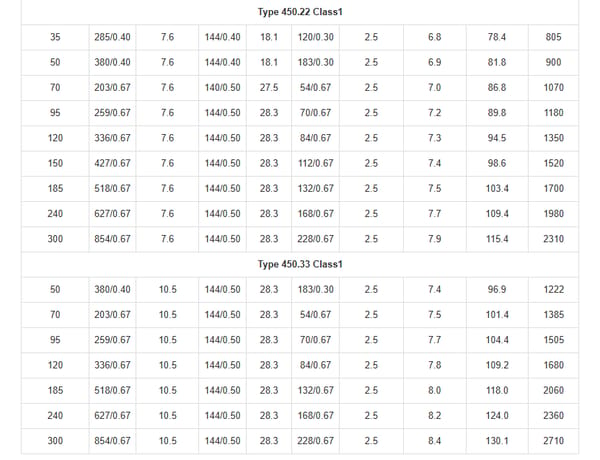

Surface Mining: Type 450.11 and Type 450.22 support draglines and shovels in gold and diamond operations.

Material Handling: Conveyor systems, critical for ore transport, rely on Type 450.6 and Type 450.11 for consistent power.

Drilling and Excavation: Type 450.22 and Type 450.33 power high-capacity drilling rigs in deep-level mining.

Installation and Maintenance Recommendations

Proper installation and maintenance are crucial for maximizing the lifespan and performance of Type 450 cables.

Installation Tips

Site Assessment: Evaluate the mining environment for hazards like moisture, abrasion, and mechanical stress to select the appropriate cable variant.

Cable Handling: Avoid sharp bends or excessive tension during installation to prevent damage to the insulation or sheath.

Connection Integrity: Ensure secure connections with compatible fittings to maintain electrical integrity.

Reeling Systems: For slow reeling applications, use Type 450.3 or Type 450.6 to leverage their lightweight design.

Compliance: Adhere to AS/NZS standards and local regulations, such as South Africa’s Mine Health and Safety Act, during installation.

Maintenance Guidelines

Regular Inspections: Check for signs of wear, cuts, or abrasion on the sheath, especially in high-traffic areas.

Cleaning: Remove dust and debris to prevent corrosion of the tinned copper conductors.

Testing: Periodically test insulation resistance and voltage handling to ensure compliance with specifications.

Storage: Store unused cables in a dry, cool environment to prevent degradation of the PCP sheath.

Repairs: Replace damaged sections promptly with matching Type 450 variants to avoid compromising safety.

Frequently Asked Questions (FAQ)

What is the Type 450 Mining Trailing Cable used for?

The Type 450 series powers mining equipment such as draglines, conveyors, pumps, and lighting systems in underground and surface operations.How do I choose the right Type 450 variant?

Select based on voltage requirements: Type 450.3 (3.3–6.6kV) for low-voltage systems, Type 450.6 (6.6–11kV) for medium-voltage, Type 450.11 (11–22kV) for heavy machinery, Type 450.22 (22–33kV) for high-voltage lines, and Type 450.33 (above 33kV) for specialized applications.Are Type 450 cables safe for underground mining?

Yes, they comply with AS/NZS standards and feature robust insulation and screening for safe operation in hazardous environments.What maintenance is required for Type 450 cables?

Regular inspections, cleaning, and insulation testing are essential to ensure longevity and safety.Can Type 450 cables be used in South Africa’s mining conditions?

Absolutely. Their durable PCP sheath and flexible design make them ideal for South Africa’s abrasive and high-stress mining environments.What standards do Type 450 cables meet?

They comply with AS/NZS 2802:2000, AS/NZS 1125, AS/NZS 3808, and AS/NZS 5000.1, ensuring global quality and safety.

The Type 450 Mining Trailing Cable series is a game-changer for South Africa’s mining industry, offering tailored solutions for diverse voltage needs and harsh environments. From the lightweight Type 450.3 to the ultra-robust Type 450.33, these cables combine durability, safety, and efficiency to power everything from small pumps to massive draglines. By adhering to strict standards and incorporating advanced materials like EPR insulation and PCP sheathing, the Type 450 series ensures reliable performance in the face of South Africa’s mining challenges. Whether you’re upgrading aging infrastructure or powering new automated systems, investing in Type 450 cables guarantees safety, efficiency, and longevity for your operations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430