Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

AS/NZS 2802 Type 455 3.3 to 33KV Mining Reeling Cable

Type 455 Mining Cable: Revolutionizing Flexibility and Durability in Reeling Applications for Drag-Lines, Shovels, Excavators, and Wharf Cranes in South Africa's Mining Sector

Type 455 3.3 to 33KV to AS/NZS 2802

Applications | These cables are designed with reduced insulation and sheath thickness, no cradle, 2 earth and 1 pilotcore (each earth and pilot are the same size) in the outer interstices. These cablesare suitable for reeling and trailingapplications where minimal diameter and mass is desired, particularly suited to stacker-reclaimer applications. |

Standards | AS/NZS 2802:2000 |

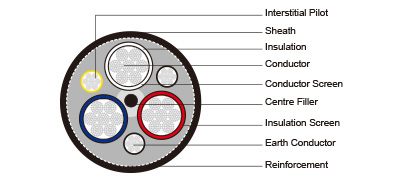

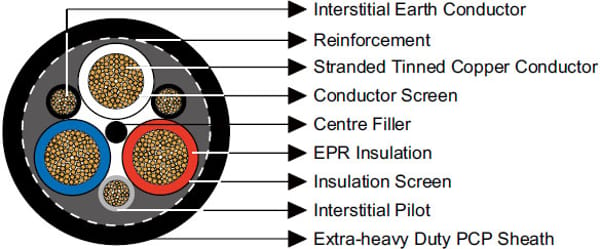

Construction  | |

3×Conductors | Flexible stranded tinned annealed copper conductor. |

Conductor Screen | Semiconductive compound (for cables having a voltage rating of 3.3/3.3kV and above). |

Insulation | EPR. |

Insulation Screen | Semiconductive elastomer. |

Filler | Elastomer centre filler. |

2×Interstitial Earth Conductor | CSP insulated flexible stranded tinned copper conductor. |

1×Interstitial Pilot | EPR covered flexible stranded tinned copper conductor. |

Textile Reinforcement | Open-weave braid reinforcement. |

Sheath | Extra-heavy duty PCP sheath.Extra-heavy duty CPE/CSP sheath can be offered upon request. |

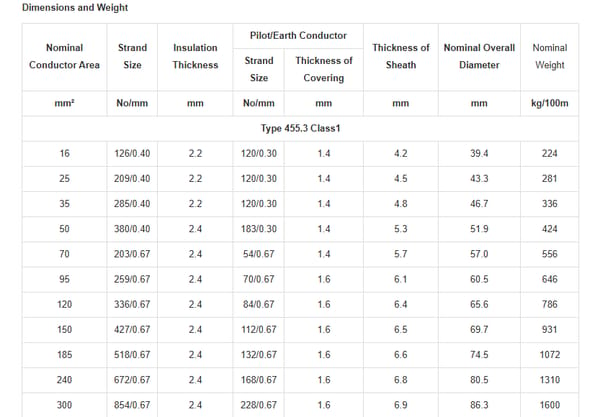

Cable Types

The series is segmented by voltage ratings, each optimized for specific power needs:

Type 455.3: For 3.3kV applications, ideal for medium-voltage setups in underground mining.

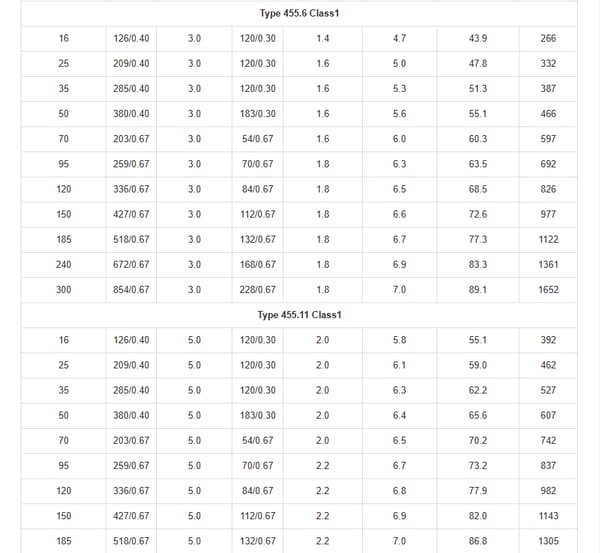

Type 455.6: Handles 6.6kV, suitable for surface operations with moderate power demands.

Type 455.11: Rated at 11kV, perfect for heavy machinery like shovels and excavators.

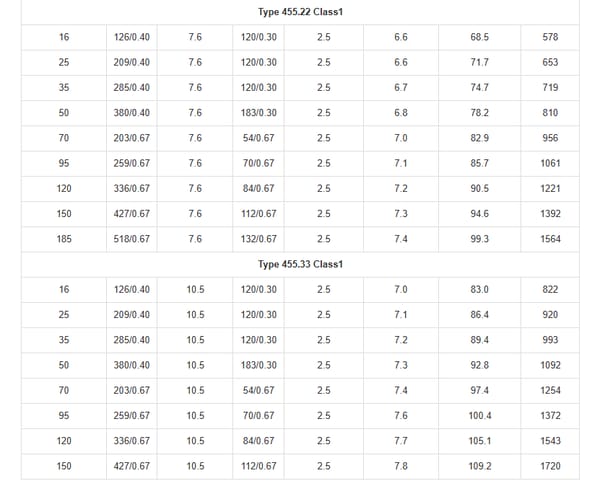

Type 455.22: For 22kV, used in high-stress reeling on drag-lines.

Type 455.33: The highest at 33kV, designed for large-scale wharf cranes and conveyor systems.

These types share a common 3+2+1 core layout: three power conductors, two interstitial earth conductors, and one interstitial pilot core. The pilot core provides reinforcement and can integrate optical fibers for automated monitoring, aligning with digitalization trends in mining.

Key Benefits of Type 455 Mining Cable

The Type 455 stands out for its blend of performance and practicality, offering benefits that directly impact mining efficiency.

Exceptional Flexibility and High Tensile Strength: Its polymer-based design handles frequent bending and unwinding, reducing wear and extending lifespan. This minimizes downtime in dynamic applications like reeling on forklifts or excavators.

Corrosion and Chemical Resistance: The HD-CSP sheath withstands oils, alkalis, and harsh liquids, ideal for oily mining sites.

Explosion-Proof and Safety Features: High-level sheathing minimizes hazards in flammable gas environments, complying with explosion-proof certifications. This is vital in South Africa's coal mines, where gas risks are prevalent.

Efficient Power Transmission: Tinned copper ensures low-resistance conductivity, delivering consistent power to equipment.

Long-Term Durability and Cost-Effectiveness: Rugged construction reduces replacements, lowering maintenance costs. Customizations in length, size, and materials add value.

Environmental Adaptability: Wide temperature range and resistance to abrasion make it suitable for both underground and surface operations.

These benefits translate to enhanced operational efficiency, improved safety, and reduced risks of failure—key in an industry where every minute counts.

Usage Scenarios in Heavy-Duty Applications

The Type 455 excels in scenarios requiring constant motion and high power.

Drag-Lines and Shovels: In open-pit mining, these machines reel cables under immense tensile forces. The Type 455's strength prevents snaps, ensuring uninterrupted digging and loading.

Excavators and Forklifts: For excavation and material handling, its flexibility supports frequent movements, powering hydraulic systems reliably.

Wharf Cranes and Conveyor Systems: At ports or processing plants, it handles reeling for heavy lifting, resisting saltwater corrosion.

Underground and Surface Mining: From drilling machinery to conveyor belts, it provides power in confined, hazardous spaces.

Material Handling Equipment: In warehouses or yards, it supports automated systems with optional fiber optics for monitoring.

In South Africa, where surface and underground operations dominate gold and platinum extraction, this cable fits seamlessly into electrification trends, powering electric vehicles and reducing reliance on diesel amid energy shortages.

Frequently Asked Questions (FAQ)

Q1: What makes Type 455 suitable for heavy-duty mining? A1: Its EPR insulation, HD-CSP sheath, and tensile reinforcement handle mechanical stress, chemicals, and temperatures from -25°C to 90°C, ensuring reliability in harsh conditions.

Q2: How does it ensure safety? A2: Explosion-proof design, fire-resistant materials, and compliance with AS/NZS standards minimize risks in gas-prone environments.

Q3: Can it be customized? A3: Yes, in length, conductor size, and sheath material to fit specific equipment like drag-lines or excavators.

Q4: What support is available for installation? A4: Manufacturers offer technical guidance on specs, compatibility, and standards compliance.

Q5: How does it fit South Africa's 2025 trends? A5: It supports electrification, reduces theft vulnerabilities, and aids in energy-efficient operations amid crises.

The Type 455 Mining Cable embodies innovation in cable technology, offering unmatched flexibility, durability, and safety for reeling applications in mining. As South Africa navigates 2025's trends—energy transitions, theft challenges, and new projects—this cable proves indispensable. By investing in it, operators gain not just power, but peace of mind and efficiency. In a sector where every connection counts, Type 455 is the link to a brighter, more resilient future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430