Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

BS 5467 Armoured Power Cables, 1900/3300V

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside buildings or for direct burial in the ground.

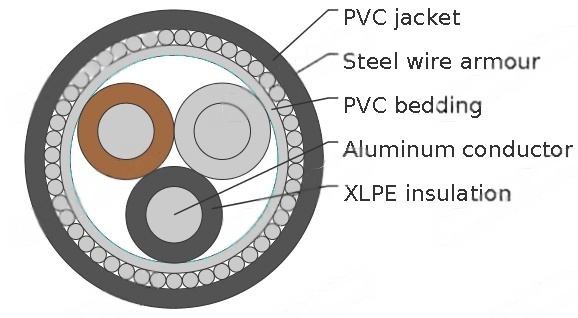

CONSTRUCTION

Conductor | Solid Aluminum or Annealed Copper conductor, circular or shaped, Class 2 to BS EN60228. |

Insulation | XLPE (Cross-Linked Polyethylene) Type GP 8 conforming to BS 7655-1.3 or type GP 6 conforming to BS 7655-1.2. |

Colour Code | 1 Core : Brown |

3 Cores : Brown, Black, Grey | |

Bedding | The bedding shall consist of an extruded layer of polymeric material consistent with the operating temperature of the cable. |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : GSWA (Galvanized Steel Wire Armour) | |

Outer Sheath | Extruded PVC, type 9 specified in BS7655-4.2. |

TECHNICAL INFORMATION

Voltage rating | 1900/3300V |

Temperature rating | 0°C to +90°C |

Min. Bending radius | 8 x overall diameter |

Flame retardant | BS EN 60332-1-2 |

CABLE PARAMETER

Single-core 1900/3300 V cables with circular stranded copper conductor

Nominal Cross-sectional Area | Strand Type | Nominal Insulation thickness | Nominal Bedding thickness | Nominal Alum Wire Armor dia. | Nominal Sheath thickness | Approx. Overall Diameter | Aprrox Weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

19/1.78 | 2 | 0.8 | 1.25 | 1.6 | 20.6 | 790 | |

19/2.14 | 2 | 0.8 | 1.25 | 1.6 | 22.4 | 1040 | |

19/2.52 | 2 | 0.8 | 1.25 | 1.6 | 24.3 | 1330 | |

37/2.03 | 2 | 1 | 1.6 | 1.7 | 27.2 | 1680 | |

37/2.25 | 2 | 1 | 1.6 | 1.7 | 28.8 | 1970 | |

37/2.52 | 2 | 1 | 1.6 | 1.8 | 30.8 | 2370 | |

61/2.25 | 2 | 1 | 1.6 | 1.8 | 33.5 | 2960 | |

61/2.52 | 2 | 1 | 1.6 | 1.9 | 36.1 | 3610 | |

61/2.85 | 2 | 1.2 | 2 | 2 | 40.5 | 4600 | |

61/3.20 | 2.2 | 1.2 | 2 | 2.1 | 44.2 | 5680 | |

127/2.52 | 2.4 | 1.2 | 2 | 2.2 | 48.8 | 7160 | |

127/2.85 | 2.6 | 1.4 | 2.5 | 2.4 | 55.4 | 9150 | |

127/3.20 | 2.8 | 1.4 | 2.5 | 2.5 | 60.6 | 11270 |

Three-core 1900/3300 V cables with stranded copper conductors

Nominal Cross-sectional Area | Strand Type | Nominal Insulation thickness | Nominal Bedding thickness | Nominal Steel Wire Armor dia. | Nominal Sheath thickness | Approx. Overall Diameter | Aprrox Weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

7/1.70 | 2 | 1 | 1.6 | 1.8 | 29.3 | 1600 | |

7/2.14 | 2 | 1 | 1.6 | 1.8 | 32.2 | 2060 | |

7/2.52 | 2 | 1 | 1.6 | 1.9 | 34.8 | 2400 | |

7/2.52 | 2 | 1 | 1.6 | 1.9 | 31.1 | 2400 | |

19/1.78 | 2 | 1.2 | 2 | 2 | 34.7 | 3200 | |

19/2.14 | 2 | 1.2 | 2 | 2.1 | 38 | 3800 | |

19/2.52 | 2 | 1.2 | 2 | 2.2 | 41.4 | 4730 | |

37/2.03 | 2 | 1.4 | 2.5 | 2.3 | 45.7 | 6070 | |

37/2.25 | 2 | 1.4 | 2.5 | 2.4 | 48.5 | 7010 | |

37/2.52 | 2 | 1.4 | 2.5 | 2.5 | 51.9 | 8270 | |

61/2.25 | 2 | 1.6 | 2.5 | 2.6 | 56.9 | 10310 | |

61/2.52 | 2 | 1.6 | 2.5 | 2.7 | 61.2 | 12300 | |

61/2.85 | 2 | 1.6 | 2.5 | 2.9 | 66.6 | 14500 |

Introduction

In the realm of electrical engineering, selecting the right cable for medium-voltage applications is crucial for ensuring safety, efficiency, and longevity. BS 5467 armoured power cables, rated at 1900/3300V, stand out as a robust solution designed to withstand harsh environments while delivering consistent performance. But what exactly makes these cables a preferred choice for power and control circuits in South Africa?

Applications of BS 5467 Armoured Power Cables

BS 5467 armoured power cables are engineered for versatility, serving both power transmission and control functions. Their primary application lies in environments requiring mechanical protection, such as inside buildings, outdoors, or direct burial in the ground. In South Africa, these cables are frequently employed in mining, petrochemical plants, and renewable energy farms, where exposure to moisture, rodents, and physical stress is common.

The heavy galvanised steel wire armour (GSWA) for multi-core variants and aluminium wire armour (AWA) for single-core types provide excellent defence against impacts and crushing forces. For instance, in direct burial scenarios—prevalent in rural electrification projects under the Integrated National Electrification Programme—the armour shields the cable from soil movement and excavation damage. This is vital in regions like the Northern Cape, where solar farms require reliable underground cabling to connect inverters to substations.

Moreover, these cables excel in control circuits, where precise signal transmission is needed alongside power delivery. Their ability to operate from 0°C to +90°C makes them suitable for South Africa's varied climate, from the frigid winters in the Drakensberg to the sweltering heat in Limpopo. The flame-retardant properties, conforming to BS EN 60332-1-2, add a layer of safety in fire-prone industrial settings, aligning with South African occupational health regulations.

Advantages and In-Depth Analysis

The BS 5467 design offers multifaceted benefits. Mechanically, the armour withstands impacts per BS standards, reducing downtime in high-risk areas. Electrically, XLPE insulation provides a dielectric strength exceeding 20kV/mm, minimising partial discharges.

In South Africa, where load shedding strains infrastructure, these cables' overload capacity (up to 130% for short durations) ensures reliability. Environmentally, PVC sheaths resist oils and acids, common in mining effluents.

A quantitative analysis: For a 3x95mm² copper cable, the ampacity might reach 250A in air (per IEC 60502-1 approximations), supporting motors in factories. Weight considerations affect logistics; aluminium reduces transport emissions, aligning with South Africa's carbon tax policies.

However, challenges include higher initial costs for armoured designs and the need for specialised termination kits to prevent moisture ingress.

Frequently Asked Questions

What is the difference between AWA and GSWA in BS 5467 cables? AWA is used in single-core cables to prevent eddy currents, while GSWA in multi-core provides stronger mechanical protection against crushing.

Are these cables suitable for direct burial in South African soil? Yes, the armour and PVC sheath protect against moisture and rodents, but backfill with sand is recommended to avoid sharp stones.

How does XLPE insulation compare to PVC in these cables? XLPE offers higher temperature ratings (90°C vs. 70°C for PVC) and better resistance to environmental stress, making it superior for medium-voltage use.

What bending radius should be observed during installation? A minimum of 8 times the overall diameter to prevent insulation damage.

Can these cables be used in flame-prone areas? Absolutely, as they comply with BS EN 60332-1-2 for flame retardancy.

Why choose aluminium over copper conductors? Aluminium is lighter and cheaper, ideal for long runs, though copper provides better conductivity for high-current needs.

BS 5467 armoured power cables for 1900/3300V applications embody engineering excellence, offering a blend of durability, efficiency, and safety tailored to South Africa's electrical demands. From their robust construction to versatile parameters, these cables—featuring XLPE insulation, GSWA/AWA, and optimised conductors—ensure reliable power distribution in challenging environments. As the nation advances towards sustainable energy, adopting such standards will mitigate risks and enhance infrastructure resilience. Whether for industrial control or underground power, the question remains: why settle for less when BS 5467 delivers proven performance?

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430