Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

BS 5467 Armoured Power Cables, 600/1000V

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside buildings or for direct burial in the ground.

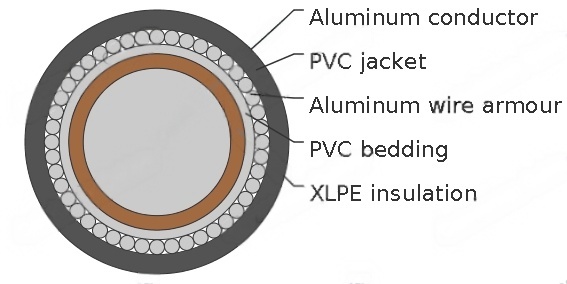

CONSTRUCTION

Conductor | Solid Aluminum or Annealed Copper conductor, circular or shaped, Class 2 to BS EN60228. |

Insulation | XLPE (Cross-Linked Polyethylene) Type GP 8 conforming to BS 7655-1.3 or type GP 6 conforming to BS 7655-1.2. |

Colour Code | 1 Core : Brown or Blue |

2 Cores : Brown, Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green/Yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Bedding | The bedding shall consist of an extruded layer of polymeric material consistent with the operating temperature of the cable. |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : GSWA (Galvanized Steel Wire Armour) | |

Outer Sheath | Extruded PVC, type 9 specified in BS7655-4.2. |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | 0°C to +90°C |

Min. Bending radius | 8 x overall diameter |

Flame retardant | BS EN 60332-1-2 |

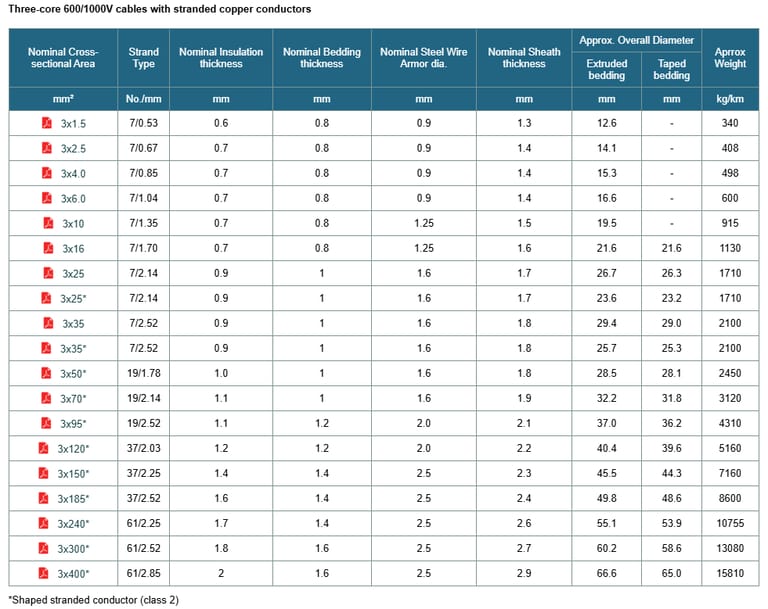

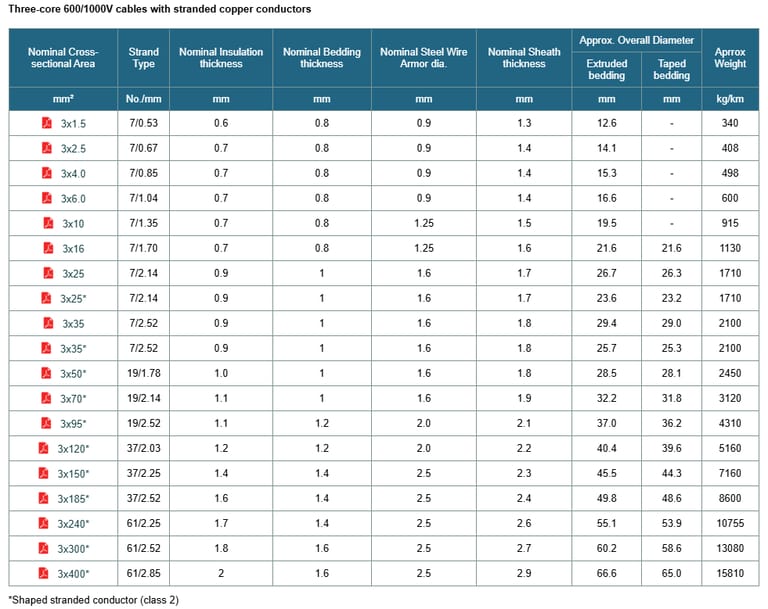

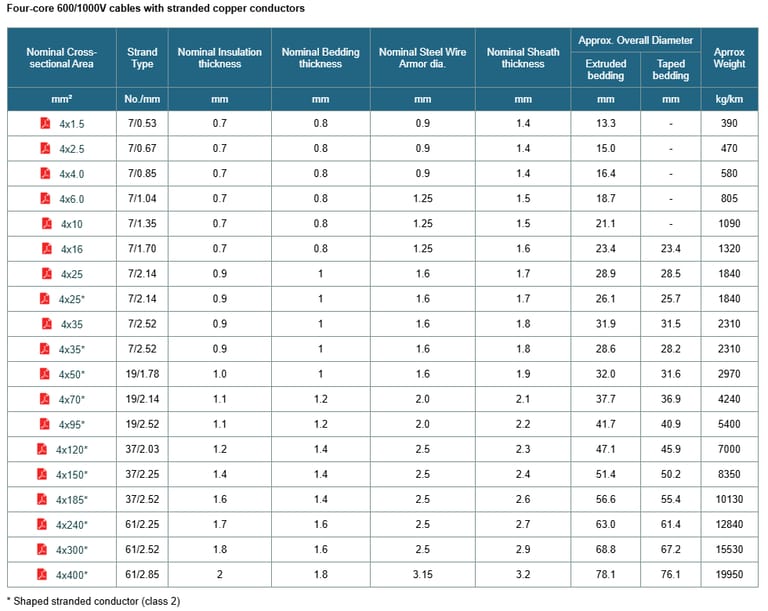

CABLE PARAMETER

Single-core 600/1000 V cables with circular stranded copper conductor

Nominal Cross-sectional Area | Strand Type | Nominal Insulation thickness | Nominal Bedding thickness | Nominal Alum Wire dia. | Nominal Sheath thickness | Approx. Overall Diameter | Aprrox Weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

19/1.78 | 1.0 | 0.8 | 0.9 | 1.5 | 17.5 | 800 | |

19/2.14 | 1.1 | 0.8 | 1.25 | 1.5 | 20.2 | 990 | |

19/2.52 | 1.1 | 0.8 | 1.25 | 1.6 | 22.3 | 1280 | |

37/2.03 | 1.2 | 0.8 | 1.25 | 1.6 | 24.2 | 1550 | |

37/2.25 | 1.4 | 1 | 1.6 | 1.7 | 27.4 | 1900 | |

37/2.52 | 1.6 | 1 | 1.6 | 1.8 | 30.0 | 2320 | |

61/2.25 | 1.7 | 1 | 1.6 | 1.8 | 32.8 | 2930 | |

61/2.52 | 1.8 | 1 | 1.6 | 1.9 | 35.6 | 3580 | |

61/2.85 | 2.0 | 1.2 | 2.0 | 2.0 | 40.5 | 4600 | |

61/3.20 | 2.2 | 1.2 | 2.0 | 2.1 | 44.2 | 5680 | |

127/2.52 | 2.4 | 1.2 | 2.0 | 2.2 | 48.8 | 7160 | |

127/2.85 | 2.6 | 1.4 | 2.5 | 2.4 | 55.4 | 9315 | |

127/3.20 | 2.8 | 1.4 | 2.5 | 2.5 | 60.6 | 11490 |

Single-core 600/1000V cables with solid aluminum conductor

Nominal Cross-sectional Area | Nominal Insulation thickness | Nominal Bedding thickness | Nominal Alum Wire Armor dia. | Armour strip | Nominal Sheath thickness | Approx.Overall Diameter | Aprrox Weight | ||

|---|---|---|---|---|---|---|---|---|---|

thickness | width | wire armor | strip armor | ||||||

mm² | mm | mm | mm | mm | mm | mm | mm | mm | kg/km |

1.0 | 0.8 | 0.9 | 0.6 | 2.4 | 1.5 | 16.3 | 15.7 | 460 | |

1.1 | 0.8 | 1.25 | 0.6 | 2.4 | 1.5 | 18.7 | 17.4 | 560 | |

1.1 | 0.8 | 1.25 | 0.6 | 2.4 | 1.6 | 20.6 | 19.3 | 690 | |

1.2 | 0.8 | 1.25 | 0.6 | 2.4 | 1.6 | 22.1 | 20.8 | 800 | |

1.4 | 1 | 1.6 | 0.6 | 2.4 | 1.7 | 25.2 | 23.2 | 970 | |

1.6 | 1 | 1.6 | 0.6 | 2.4 | 1.8 | 27.4 | 25.4 | 1150 | |

1.7 | 1 | 1.6 | 1 | 3.6 | 1.8 | 29.9 | 28.7 | 1380 | |

1.8 | 1 | 1.6 | 1 | 3.6 | 1.9 | 32.4 | 31.2 | 1640 | |

Introduction

In the realm of electrical engineering, the choice of cabling can mean the difference between seamless power distribution and catastrophic failure. BS 5467 armoured power cables, rated at 600/1000V, stand out as a robust solution designed to withstand harsh environments while ensuring efficient energy transmission. These cables, compliant with British Standard 5467, incorporate cross-linked polyethylene (XLPE) insulation and galvanised steel wire armour (GSWA) for multi-core variants or aluminium wire armour (AWA) for single-core types. But what exactly makes these cables indispensable in modern installations, from industrial sites to underground burials?

Applications and Benefits in Electrical Systems

BS 5467 armoured power cables are versatile, suitable for indoor, outdoor, and direct burial applications. Their primary role is in power distribution networks where reliability is paramount. For instance, in South Africa's mining industry, where cables must endure vibrations and moisture, the heavy galvanised steel wire armour provides exceptional defence against physical damage. This armouring not only shields the conductors from external forces but also enhances the cable's tensile strength, allowing for longer spans without sagging.

From a scientific perspective, the armour serves as a Faraday cage, reducing electromagnetic induction that could interfere with control signals in adjacent circuits. This is particularly vital in control applications, where precise voltage regulation is needed. The cables' voltage rating of 600/1000V—meaning 600V phase-to-earth and 1000V phase-to-phase—positions them ideally for low-voltage systems, such as those in commercial buildings or rural electrification projects. In direct burial scenarios, the extruded PVC outer sheath resists soil acidity and microbial degradation, ensuring longevity that can exceed 25 years under normal conditions.

One key benefit is their flame-retardant properties, conforming to BS EN 60332-1-2. This standard tests for vertical flame propagation, where the cable must self-extinguish within a specified time, preventing fire spread in confined spaces like cable trays. In South Africa, where bushfires and electrical faults pose risks, this feature aligns with national safety regulations, reducing the likelihood of arc flash incidents that could release energies up to 35,000°C.

Moreover, these cables support sustainable energy transitions. With South Africa's push towards solar and wind farms, BS 5467 cables facilitate grid integration by handling variable loads without insulation breakdown. Their temperature rating from 0°C to +90°C allows operation in diverse climates, from the arid Karoo to humid coastal regions, without compromising dielectric strength.

In-Depth Analysis: Material Science and Engineering Insights

Scientifically, BS 5467 cables exemplify composite materials. XLPE's peroxide cross-linking creates a thermoset polymer, boosting tensile strength to 20MPa and elongation at break >200%. Armour's helical lay distributes loads evenly, per Euler's buckling theory, preventing collapse under compression.

Thermal analysis reveals XLPE's superior heat dissipation compared to PVC, with thermal conductivity around 0.4 W/m·K. This allows higher current ratings without exceeding 90°C, where Arrhenius kinetics predict accelerated ageing.

Electrically, insulation thickness scales with voltage stress (E = V/d), ensuring breakdown voltages exceed 5kV/mm. Armour mitigates partial discharges, phenomena described by Paschen's law, in voids.

In South African contexts, these cables address load shedding challenges by enabling quick repairs—armour protects against vandalism. Sustainability-wise, recyclable materials like copper (95% recovery rate) align with circular economy principles.

Frequently Asked Questions

What is the difference between AWA and GSWA in BS 5467 cables? AWA (aluminium wire armour) is used in single-core cables to avoid magnetic hysteresis losses, while GSWA (galvanised steel wire armour) in multi-core provides stronger mechanical protection and is non-magnetic in balanced configurations.

Can BS 5467 cables be used in hazardous areas? Yes, with appropriate certifications like ATEX for explosive atmospheres, but always verify with SANS standards for South African zones.

How do I select the right cross-sectional area? Based on load current, using formulas like I = P/(V·√3·cosφ) for three-phase, ensuring derating for ambient temperature and grouping.

What maintenance do these cables require? Periodic visual inspections for sheath damage and insulation resistance tests (>1GΩ) per IEC 60364.

Are there eco-friendly alternatives to PVC sheathing? Low-smoke zero-halogen (LSZH) variants exist, reducing toxic emissions, though not standard in BS 5467.

BS 5467 armoured power cables, with their 600/1000V rating and robust design, embody engineering excellence for safe, efficient power delivery. From XLPE insulation's thermal resilience to GSWA's protective might, they address real-world challenges in electrical systems. As South Africa advances its infrastructure, these cables will remain pivotal, blending science with practicality for a powered future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430