Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

BS 6622 XLPE / PVC Medium Voltage 19/33 (36)kV Cable

BS 6622 XLPE/PVC Medium Voltage 19/33 (36)kV Cable

Category | Details |

|---|---|

Application | Power cables for power networks, underground and in cable ducting. Suitable for direct burial. |

Characteristics | |

Voltage Rating Uo/U (Um) | 19/33 (36)kV |

Temperature Rating | Fixed: 0°C to +90°C |

Initial Temperature at S.C.C for Metallic Screen | 80°C |

Maximum Conductor Temperature during S.C | 250°C |

Minimum Bending Radius | Fixed: 15 x overall diameter |

Construction | |

Conductor | Class 2 stranded copper conductor |

Conductor Screen | Semi-conductive XLPE (Cross-Linked Polyethylene) |

Insulation | XLPE (Cross-Linked Polyethylene) |

Insulation Screen | Semi-conductive XLPE (Cross-Linked Polyethylene) |

Metallic Screen | Individual or collective overall copper tape screen |

Filler | PET (Polyethylene Terephthalate) fibres |

Separator | Binding tape |

Bedding | PVC (Polyvinyl Chloride) |

Armour | Single core: AWA (Aluminium Wire Armoured) Multi-core: SWA (Steel Wire Armoured) |

Sheath | PVC (Polyvinyl Chloride) |

Sheath Colour | Red, Black |

Standards | |

BS 6622, EN 60228, IEC 60502-2 | |

Flame Retardant | According to IEC/EN 60332-1-2 |

Dimensions

Part No. | No. of Cores | Nominal Cross Sectional Area (mm²) | Nominal Insulation Thickness (mm) | Nominal Outer Sheath Thickness (mm) | Nominal Overall Diameter (mm) | Nominal Weight (kg/km) |

|---|---|---|---|---|---|---|

A9M33KV01070* | 1 | 70 | 8 | 2.2 | 38.8 | 2077 |

A9M33KV01095* | 1 | 95 | 8 | 2.3 | 40.3 | 2393 |

A9M33KV01120* | 1 | 120 | 8 | 2.3 | 41.7 | 2692 |

A9M33KV01150* | 1 | 150 | 8 | 2.4 | 44.7 | 3193 |

A9M33KV01185* | 1 | 185 | 8 | 2.5 | 46.4 | 3623 |

A9M33KV01240* | 1 | 240 | 8 | 2.6 | 49 | 4309 |

A9M33KV01300* | 1 | 300 | 8 | 2.6 | 51.6 | 4999 |

A9M33KV01400* | 1 | 400 | 8 | 2.7 | 54.4 | 5956 |

A9M33KV01500* | 1 | 500 | 8 | 2.8 | 58 | 7107 |

A9M33KV01630* | 1 | 630 | 8 | 3 | 63.3 | 8783 |

A9M33KV01800* | 1 | 800 | 8 | 3.1 | 67.6 | 10766 |

A9M33KV03070* | 3 | 70 | 8 | 3.5 | 77.6 | 9625 |

A9M33KV03095* | 3 | 95 | 8 | 3.7 | 81 | 10827 |

A9M33KV03120* | 3 | 120 | 8 | 3.8 | 84.4 | 12043 |

A9M33KV03150* | 3 | 150 | 8 | 3.9 | 88.1 | 13379 |

A9M33KV03185* | 3 | 185 | 8 | 4 | 91.5 | 14800 |

A9M33KV03240* | 3 | 240 | 8 | 4.2 | 97.1 | 17324 |

A9M33KV03300* | 3 | 300 | 8 | 4.3 | 102.7 | 19777 |

A9M33KV03400* | 3 | 400 | 8 | 4.6 | 109.1 | 23228 |

Colour | Code |

|---|---|

Red | RD |

Black | BK |

Electrical Characteristics - Single Core Cables

Nominal Cross Sectional Area (mm²) | Max. Conductor DC Resistance at 20°C (Ω/km) | Max. Conductor AC Resistance at Operating Temp. and 50Hz (Ω/km) | Capacitance (µF/km) | Charging Current (A/km) | Dielectric Losses (W/km) | Reactance at 50 Hz (ohm/km) | Conductor S.C.C for 1 Sec (kA) | Current Rating - Laid in Ground (A) | Current Rating - Laid in Free Air (A) |

|---|---|---|---|---|---|---|---|---|---|

70 | 0.268 | 0.342 | 0.159 | 0.947 | 72.00 | 0.146 | 10.02 | 275 | 308 |

95 | 0.193 | 0.2465 | 0.171 | 1.022 | 77.64 | 0.141 | 13.59 | 326 | 369 |

120 | 0.153 | 0.1957 | 0.184 | 1.101 | 83.67 | 0.135 | 17.17 | 368 | 421 |

150 | 0.124 | 0.1589 | 0.199 | 1.191 | 90.51 | 0.132 | 21.46 | 406 | 470 |

185 | 0.0991 | 0.1273 | 0.213 | 1.275 | 96.88 | 0.128 | 26.47 | 440 | 528 |

240 | 0.0754 | 0.0975 | 0.236 | 1.408 | 107.03 | 0.122 | 34.34 | 496 | 608 |

300 | 0.0601 | 0.0784 | 0.258 | 1.541 | 117.11 | 0.118 | 42.93 | 545 | 679 |

400 | 0.047 | 0.0623 | 0.282 | 1.684 | 127.99 | 0.113 | 57.23 | 597 | 758 |

500 | 0.0366 | 0.0498 | 0.313 | 1.87 | 142.16 | 0.109 | 71.54 | 650 | 844 |

630 | 0.0283 | 0.0401 | 0.356 | 2.127 | 161.68 | 0.106 | 90.14 | 699 | 931 |

800 | 0.0221 | 0.0332 | 0.394 | 2.35 | 178.65 | 0.102 | 114.47 | 744 | 1013 |

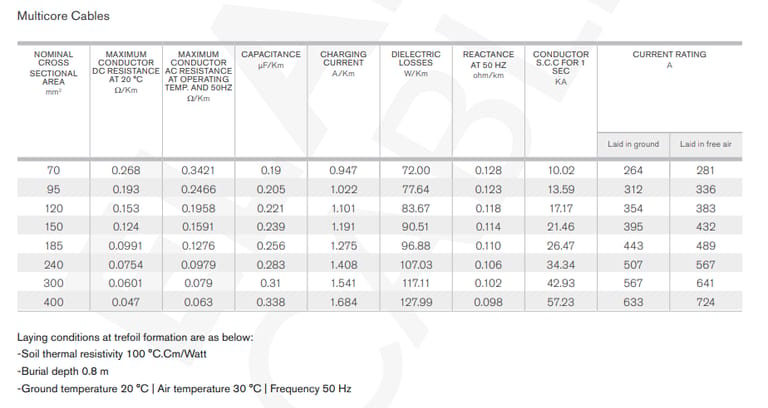

Electrical Characteristics - Multicore Cables

What is the BS 6622 XLPE/PVC 19/33 (36)kV Cable?

The BS 6622 standard governs the design and performance of medium voltage cables rated at 19/33 (36)kV, meaning they operate with a phase-to-earth voltage (Uo) of 19 kV, a phase-to-phase voltage (U) of 33 kV, and a maximum system voltage (Um) of 36 kV. These cables are engineered for power networks, underground installations, and cable ducting, with the ability to withstand direct burial in challenging environments. Their construction ensures durability, safety, and efficient power transmission, making them ideal for South Africa’s diverse electrical demands.

Key Construction Features

The BS 6622 cable is meticulously designed with components that enhance its performance:

Conductor: Made of Class 2 stranded copper, offering excellent conductivity and flexibility.

Conductor Screen: A layer of semi-conductive XLPE (Cross-Linked Polyethylene) reduces electrical stress at the conductor-insulation interface.

Insulation: XLPE provides superior thermal and electrical properties, capable of operating at temperatures up to 90°C under normal conditions and 250°C during short-circuit conditions.

Insulation Screen: Another semi-conductive XLPE layer ensures uniform electric field distribution.

Metallic Screen: Copper tape (individual or collective) shields the cable from electromagnetic interference and fault currents.

Filler: PET (Polyethylene Terephthalate) fibres maintain structural integrity.

Separator: Binding tape holds the cable components together.

Bedding: PVC (Polyvinyl Chloride) provides additional protection.

Armour: Aluminium Wire Armour (AWA) for single-core cables or Steel Wire Armour (SWA) for multi-core cables enhances mechanical strength.

Sheath: A PVC sheath in red or black protects against environmental factors and complies with IEC/EN 60332-1-2 flame retardant standards.

The minimum bending radius of 15 times the overall diameter ensures safe installation without compromising the cable’s integrity.

Applications in South Africa

The BS 6622 XLPE/PVC cable is widely used in South Africa’s power distribution networks, particularly for:

Underground Power Networks: In cities like Cape Town and Durban, where aesthetic and safety considerations favor underground cabling.

Direct Burial: Ideal for rural electrification projects in provinces like Limpopo, where cables must withstand harsh environmental conditions.

Cable Ducting: Used in industrial complexes in Gauteng, ensuring reliable power supply to manufacturing plants.

Renewable Energy Projects: Supporting connections to solar and wind farms in the Northern Cape, where high current ratings are essential.

Case Study: Eskom’s Rural Electrification Program

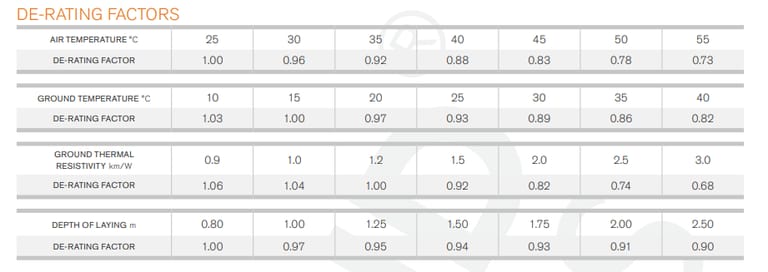

Eskom, South Africa’s primary electricity supplier, has been expanding rural electrification to address energy poverty. In a 2023 project in the Eastern Cape, BS 6622 single-core 150 mm² cables were used for a 50 km underground distribution line. The cables’ XLPE insulation ensured minimal dielectric losses, while the AWA provided protection against rocky terrain. Despite high ground temperatures (up to 35°C), de-rating factors were applied, maintaining a current rating of approximately 395 A when laid in the ground. This project successfully powered over 1,000 households, demonstrating the cable’s reliability in challenging conditions.

Installation Considerations

Proper installation is crucial for maximizing the BS 6622 cable’s performance:

Laying Conditions: Cables are typically installed in trefoil formation for three-core cables, with a burial depth of 0.8 m and soil thermal resistivity of 100 °C·cm/W.

Temperature Management: South Africa’s hot climate necessitates adherence to de-rating factors to prevent overheating.

Bending Radius: A minimum of 15 x overall diameter avoids insulation damage during installation.

Standards Compliance: Adherence to BS 6622, EN 60228, and IEC 60502-2 ensures safety and performance.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430