Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

BS 6724 AWA LSZH BASEC Single Core 0.6/1kV Cable

BS 6724 Copper Conductor Single Core AWA LSZH BASEC 0.6/1kV Cable

Category | Details |

|---|---|

Application | Single core LSZH cable with aluminium wire armour (AWA). Power and auxiliary fixed wiring cables for use in power networks, underground, outdoor and indoor applications, and for use in cable ducting. For installation where fire, smoke emission, and toxic fumes create a potential threat to life and equipment. |

Characteristics | |

Voltage Rating (Uo/U) | 0.6/1kV |

Temperature Rating | Fixed: -20°C to +90°C |

Minimum Bending Radius | Fixed: 8 x overall diameter |

Construction | |

Conductor | Class 2 stranded copper conductor |

Insulation | XLPE (Cross-Linked Polyethylene) |

Bedding | LSZH (Low Smoke Zero Halogen) |

Armour | AWA (Aluminium Wire Armour) |

Sheath | LSZH (Low Smoke Zero Halogen) |

Core Identification | Brown |

Sheath Colour | Black |

Standards | BS 6724, IEC/EN 60502-1, EN 60228, Low Smoke Zero Halogen to IEC/EN 60754-1/2, IEC/EN 61034-2, Flame Retardant to IEC/EN 60332-1-2, IEC/EN 60332-3-24 Cat C, UV Resistant |

Cable Third-Party Accreditations | We supply BASEC approved products. Cables are tested and certified by BASEC, The British Approvals Service for Cables. |

Technical Specifications:

Construction and Materials

The cable features a Class 2 stranded copper conductor, which provides excellent conductivity while allowing flexibility for installation. Copper's low resistance ensures minimal energy loss, making it ideal for efficient power transmission. The insulation is cross-linked polyethylene (XLPE), a thermoset material that withstands temperatures up to 90°C during operation and offers superior electrical insulation compared to traditional PVC.

Surrounding the insulation is LSZH bedding, followed by AWA for mechanical protection. The aluminium wire armour shields against impacts, rodents, and external pressures, common in underground or ducted setups. The outer sheath is also LSZH, ensuring low smoke and zero halogen emissions in case of fire—crucial for preventing toxic fumes that could endanger lives or damage equipment. The core is identified as brown, with a black sheath, and the cable is UV-resistant, flame retardant (per IEC/EN 60332-1-2 and 60332-3-24 Cat C), and low smoke (IEC/EN 61034-2).

Temperature ratings range from -20°C to +90°C when fixed, with a minimum bending radius of 8 times the overall diameter, facilitating easier routing in tight spaces.

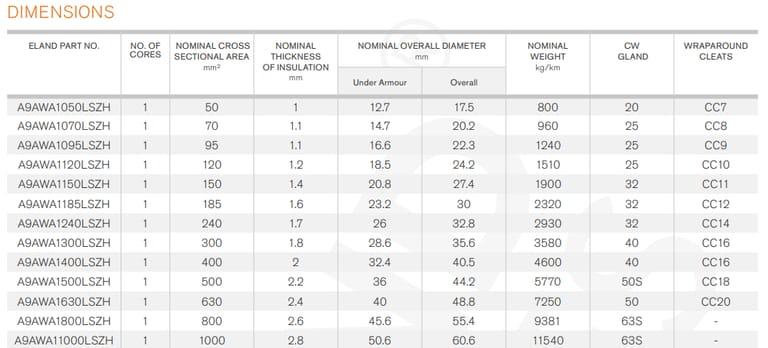

Dimensions and Weights

Available in nominal cross-sectional areas from 50 mm² to 1000 mm², the cable's dimensions vary accordingly. For instance:

A 50 mm² variant has a 1 mm insulation thickness, 12.7 mm under-armour diameter, 17.5 mm overall diameter, and weighs 800 kg/km.

Larger sizes, like 1000 mm², feature 2.8 mm insulation, 50.6 mm under-armour diameter, 60.6 mm overall, and a hefty 11,540 kg/km.

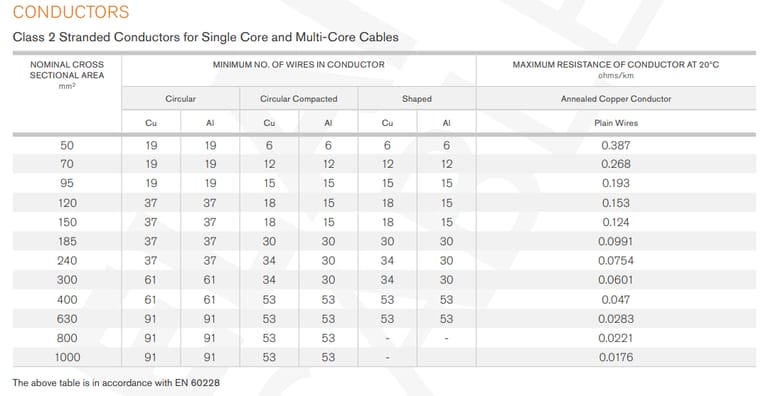

These specs, compliant with EN 60228, ensure scalability for different loads. Conductors are stranded (e.g., minimum 19 wires for 50-95 mm², up to 91 for larger sizes), with maximum resistance at 20°C decreasing from 0.387 ohms/km (50 mm²) to 0.0176 ohms/km (1000 mm²), optimizing for low heat generation.

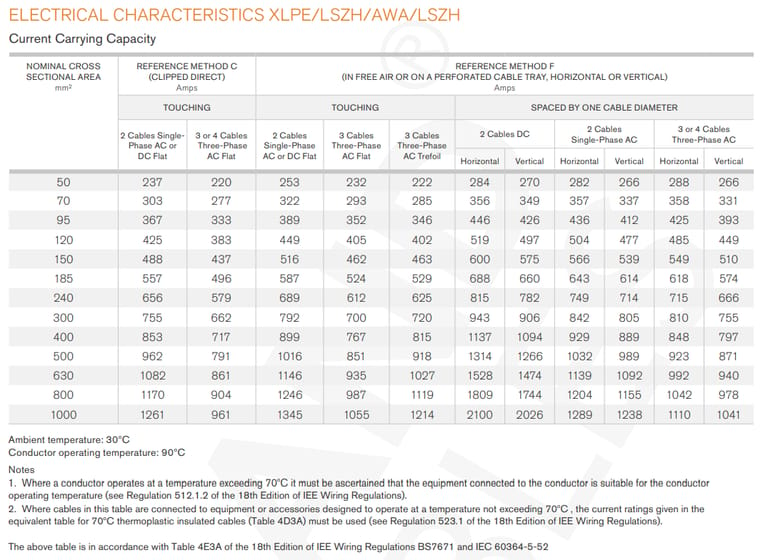

Electrical Characteristics: Current Carrying Capacity

Current ratings are impressive, based on IEC 60364-5-52 and BS7671 Table 4E3A. For clipped direct (Method C) installation:

A 50 mm² cable handles 237 A (single-phase AC/DC) or 220 A (three-phase AC flat).

At 1000 mm², it reaches 1261 A and 961 A, respectively.

In free air (Method F), ratings increase, e.g., 288 A for 50 mm² in spaced three-phase AC horizontal setup. Ambient temperature is assumed at 30°C, with conductor at 90°C. Notes emphasize compatibility with connected equipment, per IEE Wiring Regulations 512.1.2 and 523.1—if endpoints are rated only to 70°C, derate accordingly.

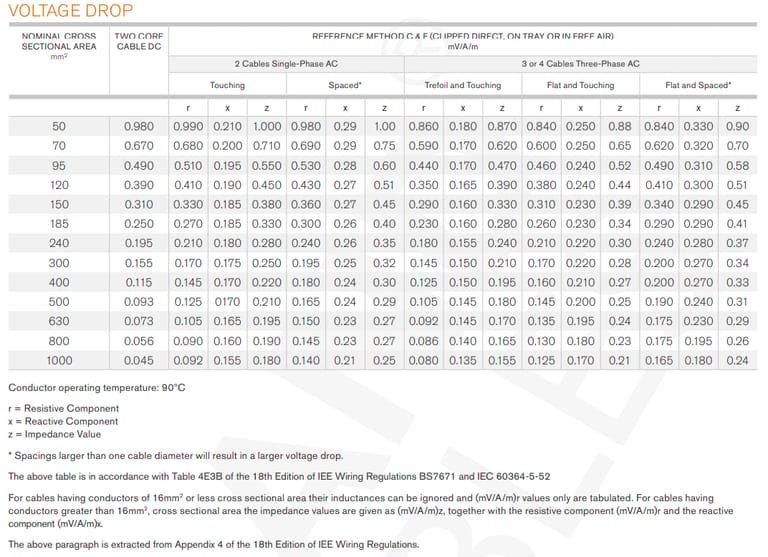

Voltage Drop Analysis

Voltage drop, critical for maintaining efficiency over distances, is detailed in Table 4E3B. For a 50 mm² cable in two-core DC: 0.980 mV/A/m. In single-phase AC touching: resistive (r) 0.990, reactive (x) 0.210, impedance (z) 1.000 mV/A/m. Larger cables show lower drops, e.g., 1000 mm² at 0.045 mV/A/m DC. For areas over 16 mm², full r, x, z values account for inductance, ensuring precise system design.

These specs highlight the cable's balance of performance and safety, making it a go-to for engineers prioritizing longevity and compliance.

Usage Scenarios:

The BS 6724 Copper Conductor Single Core AWA LSZH BASEC 0.6/1kV Cable excels in environments where fire safety and durability are paramount. Its primary application is in power networks for fixed wiring, including underground, outdoor, indoor, and ducted installations. The LSZH properties make it essential where smoke and toxic fumes pose risks, such as hospitals, schools, tunnels, and high-occupancy buildings.

In industrial settings, it's used for auxiliary control and power circuits, offering protection via AWA against abrasion and impacts. For direct burial in free-draining soil, it resists moisture and mechanical stress. Renewable energy projects benefit from its UV resistance and high current capacity, connecting solar panels or wind turbines to grids. In urban infrastructure, it supports street lighting, substations, and rail signaling, where reliability prevents outages.

South Africa's context amplifies its value: With frequent power disruptions and fire hazards from informal settlements, this cable's flame-retardant design aligns with local safety trends. It's also suitable for mining operations under SANS standards, equivalents to BS 6724, ensuring safe power in confined spaces.

Frequently Asked Questions:

What makes LSZH superior to PVC in the BS 6724 cable? LSZH emits low smoke and no halogens during fires, improving visibility and reducing toxicity, unlike PVC which releases harmful gases.

Is this cable suitable for direct burial? Yes, with AWA protection, it's ideal for underground in free-draining soil, per BS 6724.

How do I select the right cross-sectional area? Based on load: e.g., 50 mm² for 237 A clipped direct; consult voltage drop tables for distance.

What about compatibility with South African standards? While BS 6724 is British, equivalents like SANS 1507 ensure compliance; BASEC certification adds global assurance.

Can it handle high temperatures? Yes, up to 90°C operating, but derate if connected to 70°C-rated equipment.

Is it theft-resistant? AWA deters casual theft, though copper conductors remain attractive; combine with security measures

The BS 6724 Copper Conductor Single Core AWA LSZH BASEC 0.6/1kV Cable exemplifies how cable technology evolves to meet modern demands for safety, efficiency, and durability. Its XLPE insulation, AWA protection, and LSZH materials provide a robust solution for diverse applications, from power networks to renewables. In South Africa, amid trends like renewable expansion and anti-theft innovations, it offers valuable tools for infrastructure resilience. As the nation targets net-zero by 2050, adopting such cables will be key to a reliable, fire-safe energy ecosystem. Whether you're an engineer, policymaker, or enthusiast, understanding this technology reveals the invisible threads powering our world.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430