Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Cat 5e S/FTP 0.22mm² IEC60092

Application | These Cat5e S/FTP cables are manufactured in accordance with IEC 61156-5 requirements, can support all Class D applications like Ethernet, Fast Ethernet, Gigabit Ethernet, suitable for basic voice and data installations up to 100MHz. |

Standards | EN 50173-1 |

Construction | |

Conductors | Stranded copper conductor. |

Insulation | PE. |

Twinning | Two coloured insulated conductors twisted together to form a pair. |

Individual Screen | Al/polyester tape. |

Overall Screen | Tinned copper wire braid. |

Outer Sheath | Oil resistant, flame retardant and halogen free LSOH (SHF2). |

Core Identification | Pair 1: White, Blue |

Electrical Properties

Maximum DC Loop Resistance | Ω/km | 158 |

Maximum Resistance Unbalance |

| 2% |

Minimum Insulation Resistance (500V) | 5000 | |

Nominal Capacitance @800Hz | nF/km | 43 |

Maximum Capacitance Unbalance (pair to ground) | pF/km | 1500 |

Mean Characteristic Impedance @100MHz | Ω | 100 ± 5 |

Nominal Velocity of Propagation |

| 0.75c |

Maximum Propagation Delay | ns/100 m | 450 |

Maximum Delay Skew | ns/100 m | 15 |

Maximum Transfer Impedance @1MHz | mΩ /m | 10 |

Maximum Transfer Impedance @10MHz | mΩ /m | 8 |

Maximum Transfer Impedance @30MHz | mΩ /m | 10 |

Minimum Coupling Attenuation | dB | 85 |

Nominal Transmission Characteristics @20℃

F | Attenuation | NEXT | ACR | Return Loss | PS-NEXT | PS-ACR | ELFEXT | PS-ELFEXT |

MHz | dB/100m | dB | dB/100m | dB | dB | dB/100m | dB/100m | dB/100m |

1 | 2.1 | 90 | 88 |

| 87 | 85 | 85 | 82 |

4 | 4.0 | 90 | 86 | 27 | 87 | 83 | 85 | 82 |

10 | 6.3 | 90 | 84 | 30 | 87 | 81 | 79 | 76 |

16 | 8.0 | 90 | 82 | 30 | 87 | 79 | 75 | 72 |

20 | 9.0 | 90 | 81 | 30 | 87 | 78 | 73 | 70 |

31.25 | 11.4 | 90 | 79 | 30 | 87 | 76 | 69 | 66 |

62.5 | 16.5 | 86 | 70 | 30 | 83 | 67 | 63 | 60 |

100 | 21.3 | 83 | 62 | 30 | 80 | 59 | 59 | 56 |

155.0 | 24.2 | 81 | 57 | 26 | 78 | 54 | 57 | 54 |

200.0 | 31.5 | 78 | 47 | 25 | 75 | 44 | 53 | 50 |

250 | 35.8 | 77 | 41 | 25 | 74 | 38 | 51 | 48 |

300.0 | 47.1 | 73 | 26 | 23 | 70 | 23 | 47 | 44 |

600.0 | 60.1 | 71 | 11 | 20 | 68 | 8 | 44 | 41 |

Mechanical and Thermal Properties

Bending Radius: 8×OD (during installation); 4×OD (fixed installed)

Temperature Range: -40℃ ~ +85℃

Dimensions and Weight

Part No. | Construction No. of elements×No. of cores in element×Cross section(mm²) | Nominal Insulation Thickness mm | Nominal Sheath Thickness mm | Nominal Overall Diameter mm | Nominal Weight kg/km |

UE092-S/FTPCAT5E4P22S | 4×2×0.22 | 0.4 | 0.75 | 7.7 | 68 |

Introduction

In the ever-evolving landscape of data communication, Category 5e (Cat5e) cables remain a cornerstone for reliable networking solutions. Among these, the Shielded/Foiled Twisted Pair (S/FTP) variant stands out for its enhanced protection against electromagnetic interference (EMI), making it ideal for demanding environments. This article delves into the specifics of Cat5e S/FTP cables compliant with IEC 60092 standards, focusing on the 0.22mm² cross-section model, such as the UE092-S/FTPCAT5E4P22S. These cables are engineered for offshore and marine applications, where durability, flame retardancy, and halogen-free properties are paramount.

Manufactured to support Class D applications up to 100MHz, including Ethernet, Fast Ethernet, and Gigabit Ethernet, these cables ensure seamless voice and data transmission. Their compliance with international standards like EN 50173-1, EN 50288-2-1, ISO/IEC 11801, and IEC 61156-5 underscores their quality, while fire safety features aligned with IEC 60332-3-24, IEC 60754-1/2, and IEC 61034-1/2 make them suitable for safety-critical installations. The Low Smoke Zero Halogen (LSOH) SHF2 outer sheath further enhances their applicability in confined spaces, such as ships and oil platforms, by minimising toxic emissions during fires.

Construction and Design

The construction of Cat5e S/FTP 0.22mm² IEC 60092 cables is meticulously designed to balance flexibility, durability, and signal integrity. At the core are stranded copper conductors, each with a cross-section of 0.22mm², providing excellent conductivity while allowing for bending without fatigue. Stranded conductors, unlike solid ones, consist of multiple thin wires twisted together, reducing the risk of breakage in vibrational environments common in marine applications.

Insulation is provided by polyethylene (PE), a dielectric material known for its low capacitance and high insulation resistance. This ensures minimal signal loss and crosstalk. The twinning process involves pairing two insulated conductors – one solid colour and one white with a colour stripe – to form four pairs: white/blue, white/orange, white/green, and white/brown. This colour coding facilitates easy identification during installation and maintenance.

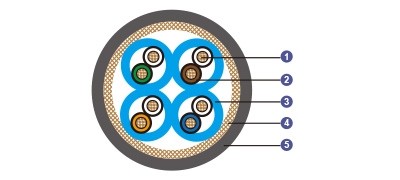

Shielding is a hallmark of S/FTP design. Each pair is individually screened with an aluminium/polyester (Al/PET) tape, which provides foil shielding to block high-frequency interference. An overall tinned copper wire braid adds a layer of braided shielding, enhancing protection against low-frequency EMI and providing mechanical strength. The tinned copper resists corrosion, crucial in salty marine atmospheres.

The outer sheath is an oil-resistant, flame-retardant, halogen-free LSOH compound classified as SHF2. This material withstands hydrocarbons, making it suitable for oil rigs, and emits low smoke and no halogens in fires, aligning with IEC 60092 requirements. The sheath's nominal thickness of 0.75mm contributes to an overall diameter of 7.7mm, balancing compactness with robustness. Visually, a cross-section reveals the symmetrical arrangement of pairs around a central axis, optimising impedance stability. This design minimises alien crosstalk, a common issue in bundled cable installations.

In professional terminology, this is a 4×2×0.22 construction, denoting four pairs of 0.22mm² conductors. The stranded nature (typically 7/0.20mm strands) enhances flexibility, with a bending radius of 8×OD during installation and 4×OD when fixed, preventing signal degradation from sharp bends.

Usage Scenarios

Cat5e S/FTP IEC 60092 cables excel in basic voice and data installations but shine in harsh environments. In marine settings, they support shipboard networks for navigation, communication, and automation systems. Their oil resistance and flame retardancy make them ideal for oil rigs, where exposure to hydrocarbons and fire risks is high.

In industrial applications, they provide reliable connectivity in factories with EMI from machinery. For offshore wind farms or refineries, the halogen-free sheath ensures safety. Installation best practices include proper grounding of the shield to drain EMI, using compatible RJ45 connectors, and avoiding excessive bends.

South African Case Studies

South Africa's diverse economy offers compelling case studies for these cables. In the offshore sector, PetroSA's FA Platform off Mossel Bay utilises similar marine-grade Cat5e S/FTP cables for data transmission in control systems. Deployed in 2018, these cables withstand corrosive sea air and vibrations, ensuring uninterrupted communication between platform modules and onshore facilities. The SHF2 sheath's oil resistance proved vital during maintenance involving lubricants, preventing degradation and maintaining Gigabit speeds for real-time monitoring.

Cat5e S/FTP 0.22mm² IEC 60092 cables represent a pinnacle of engineering for reliable data communication in demanding environments. Their construction, properties, and compliance ensure performance and safety, particularly in marine and industrial sectors. In South Africa, case studies from PetroSA, TotalEnergies, and mining operations underscore their value, driving efficiency and innovation. As connectivity demands grow, these cables will continue to play a vital role.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430