Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Feichun (N)SHTOEU Low Voltage Cable for Vertical Reeling

Feichun (N)SHTOEU 0.6/1KV: The Ultimate Reeling Cable for Extreme Vertical Applications in South Africa’s Heavy Industries

Feichun (N)SHTOEU Low Voltage Cable for Vertical Reeling

Application | Flexible low voltage reeling cable for extreme mechanical stresses, specially designed for vertical reeling operation (spreader reeling application). |

Global Data | |

Type Designation | (N)SHTOEU-J/-O |

Standard | Based on DIN VDE 0250-814 |

Certifications / Approvals | GOST-R |

Design Features | |

Conductor | Electrolytic bare copper, very finely stranded class FS |

Insulation | Special thermoplastic compound with high stability, best insulation resistance, and excellent gliding characteristic |

Core Identification | Black colored insulation with light printed numbers, earth conductor green-yellow |

Individual Screen | Braid screen of tinned copper wires, transfer impedance optimized at 30 MHz. Surface covered: at least 60% for shielded cores; at least 80% for twisted pairs |

Core Arrangement | Laid-up in a maximum of 3 layers |

Support Element | Central aramide support element to increase loading capability (kN value designates breaking load) |

Sheath System | |

Inner Sheath | PROTOFIRM Special: High-grade special compound based on PCP, color: yellow |

Anti-torsion Braid | Reinforced braid of polyester threads in a vulcanized bond between sheaths, providing high strength |

Outer Sheath | PROTOFIRM Special: Abrasion and tear-resistant special rubber compound based on PCP, color: yellow |

Marking | (N)SHTOEU-J/-O (number of cores)x(cross-section) |

Electrical Parameters | Rated Voltage | 0.6/1 kV (600/1000V) |

Max. Permissible Operating Voltage (AC) | 0.7/1.2 kV | |

Max. Permissible Operating Voltage (DC) | 0.9/1.8 kV | |

AC Test Voltage | 3.5 kV (5 Min.) | |

Data Transmission | With special elements: ASI-Bus, Profibus, CAN-Bus, Industrial Ethernet. Alternatively: fibre optics for all bus protocols. | |

Current Carrying Capacity Description | Acc. to DIN VDE 0298-4 | |

Chemical Parameters | Resistance to Oil | Acc. to DIN EN 60811-404; DIN VDE 0473-811-404, paragraph 10 |

Weather Resistance | Unrestricted use outdoors and indoors, resistant to ozone, UV, and moisture | |

Water Resistance | Given and verified in long-term tests | |

Thermal Parameters | Max. Permissible Temperature at Conductor | 90 °C |

Max. Short Circuit Temperature of the Conductor | 250 °C | |

Ambient Temperature for Fixed Installation | Min -50 °C; Max +80 °C | |

Ambient Temperature in Fully Flexible Operation | Min -35 °C; Max +80 °C | |

Mechanical Parameters | Max. Tensile Load | Increased tensile load through additional support elements (see table) |

Torsional Stress | ± 50 °/m | |

Min. Bending Radius | Acc. to DIN VDE 0298 part 3 | |

Min. Distance with S-type Directional Changes | 20 x D | |

Travel Speed (Hoist, Vertical Reeling) | Up to 240 m/min; consult manufacturer for speeds beyond 240 m/min | |

Additional Tests | Reversed bending test, roller bending test, torsional stress test |

What is the Feichun (N)SHTOEU Cable?

The Feichun (N)SHTOEU 0.6/1KV is a flexible, low-voltage reeling cable designed specifically for vertical applications under extreme mechanical stress. Unlike standard cables, it is built to handle high tensile loads, torsional stress, and reversed bending, making it ideal for dynamic operations like vertical reeling in spreader systems. Its robust construction, incorporating materials like polychloroprene (PCP) and aramid fibers, ensures durability and reliability in challenging environments, such as South Africa’s deep-level mines and port operations.

Cable Types and Configurations

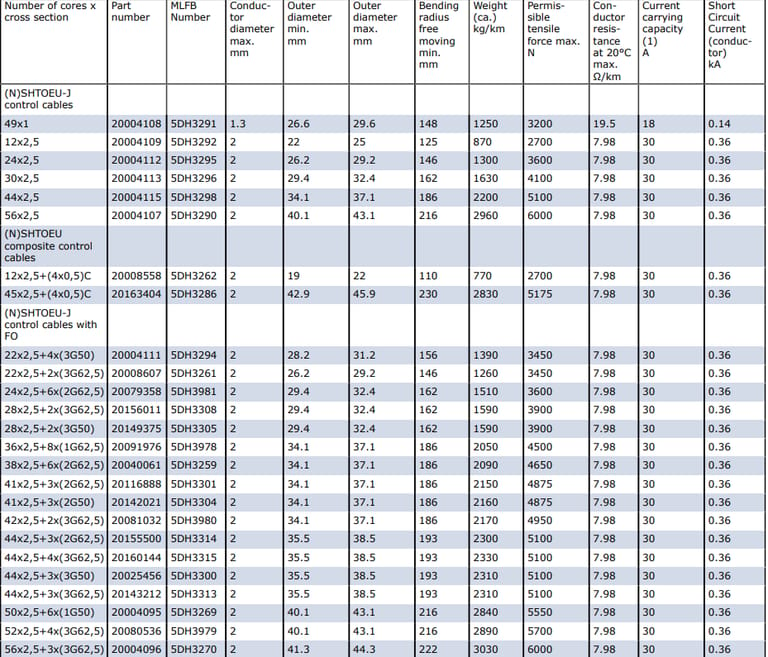

The (N)SHTOEU comes in various configurations to suit different operational needs:

Control Cables: Available with multiple cores (e.g., 49x1 mm², 12x2.5 mm², up to 56x2.5 mm²), designed for precise control in lifting systems.

Composite Control Cables: Combine power and data transmission, such as 12x2.5+(4x0.5)C, integrating shielded cores for signal integrity.

Cables with Fiber Optics: Include fiber optic elements (e.g., 22x2.5+4x(3G50)) for high-speed data transmission alongside power delivery, supporting protocols like Profibus and Industrial Ethernet.

These configurations make the cable versatile for applications requiring both power and data in extreme conditions.

Benefits of the Feichun (N)SHTOEU

Unmatched Durability: Withstands high tensile forces, bending, and torsional stress, reducing downtime in critical operations.

Environmental Resistance: Resists oil, UV, ozone, and seawater, ideal for South Africa’s coastal and mining environments.

Flexibility: Finely stranded copper and layered construction ensure smooth reeling at high speeds.

Data Integration: Optional fiber optics enable simultaneous power and high-speed data transmission, critical for modern automated systems.

Longevity: High-quality materials minimize fatigue, extending cable lifespan even under continuous dynamic stress.

Usage Scenarios in South Africa’s Mining and Heavy Industry

Case Study 1: Deep-Level Gold Mining in Gauteng

South Africa’s gold mines, such as those in the Witwatersrand Basin, operate at depths exceeding 3 km, where vertical hoisting systems are critical. In 2024, a leading gold mine in Gauteng upgraded its hoist cables to Feichun CORDAFLEX (SMK)-V 44x2.5 mm² with fiber optics. The mine faced challenges with cable fatigue due to high travel speeds (200 m/min) and exposure to abrasive dust and moisture. The CORDAFLEX cable’s aramid support and PCP sheath reduced maintenance downtime by 30%, while integrated fiber optics enabled real-time monitoring of hoist operations, improving safety and efficiency.

Case Study 2: Port Operations in Durban

The Port of Durban, a key hub for South Africa’s trade, relies on high-performance cranes for container handling. In early 2025, a crane operator adopted the CORDAFLEX (SMK)-V 24x2.5 mm² for its spreader reeling system. The cable’s seawater and UV resistance, combined with its ability to handle torsional stress (±50°/m), ensured reliable performance in the humid, saline environment. This upgrade reduced cable replacements by 25%, saving costs and minimizing operational disruptions.

Frequently Asked Questions (FAQ)

1. What makes the Feichun (N)SHTOEU suitable for vertical reeling?

Its specialized construction, including aramid support, finely stranded copper, and robust PCP sheaths, ensures it can handle high tensile loads, torsional stress, and bending at speeds up to 240 m/min.

2. Can it be used in South Africa’s coastal environments?

Yes, the cable’s outer sheath is resistant to seawater, UV, and ozone, making it ideal for ports like Durban or Cape Town.

3. How does the fiber optic option benefit mining operations?

Integrated fiber optics enable high-speed data transmission, supporting real-time monitoring and control in automated mining systems.

4. What maintenance is required to extend the cable’s lifespan?

Regular inspections for wear, proper tension control, and cleaning to remove contaminants are essential to maximize durability.

5. Is the cable compliant with international standards?

Yes, it meets DIN VDE 0250-814, DIN EN 60811-404, and EN/IEC 60332-1-2, ensuring global reliability.

6. What are the risks of improper installation?

Exceeding the recommended bending radius or tension can lead to insulation damage or premature fatigue, reducing the cable’s lifespan.

Feichun (N)SHTOEU 0.6/1KV is a game-changer for South Africa’s mining and heavy industry sectors, offering unmatched durability, flexibility, and environmental resistance. Its advanced construction, compliance with global standards, and optional fiber optic integration make it ideal for extreme vertical reeling applications, from deep-level mines to coastal ports. By addressing challenges like high tensile stress, harsh environments, and cable fatigue, it ensures reliable performance and cost savings. For port operators, crane manufacturers, and mining engineers, investing in the CORDAFLEX (SMK)-V means choosing excellence in reeling cable technology. Contact Feichun Cable today to explore tailored solutions for your toughest applications.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430