Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Drincable 800 Cable

Drincable 800: A WRAS-approved Submersible Cable for Potable Water, Mining, and More

Category | Details |

|---|---|

Application | WRAS-approved cable for permanent submersion in potable water up to 800m. Suitable for submersible pumps in mining, drinking water, depuration/chlorination systems, swimming pool lighting, aquariums, and food/drink processing systems. Water resistance tested to EN 50525-2-21 (AD8 condition). |

Characteristics | |

Voltage Rating (Uo/U) | 0.6/1kV |

Test Voltage | 4kV |

Temperature Rating | -25°C to +90°C |

Maximum Water Temperature | +80°C |

Minimum Bending Radius | Fixed: 3 x overall diameter |

Construction | |

Conductor | Class 5 tinned copper conductor |

Insulation | EPR compound |

Sheath | Elastomeric cross-linked compound |

Core Identification | |

3 Core | Blue, Brown, Green/Yellow |

4 Core | Brown, Black, Grey, Green/Yellow |

5 Core | Blue, Brown, Black, Grey, Green/Yellow |

Sheath Colour | Light Blue |

Standards | IEC 60811-2-1, EN 50525-2-21, EN 50363-1, IEC/EN 60228, KTW, DVGW W270, DM174/04 |

Introduction to the Drincable 800

In the world of electrical engineering, cables are the unsung heroes that power our modern infrastructure. Among them, the Drincable 800 stands out as a specialized solution designed for demanding environments, particularly those involving permanent submersion in potable water up to depths of 800 meters. This WRAS-approved cable is engineered for applications requiring exceptional chemical resistance, abrasion resistance, and durability, such as submersible pumps in mining, drinking water systems, and even aquarium lighting.

Benefits of the Drincable 800

The Drincable 800 offers several advantages that make it a preferred choice for submersible applications:

Water Resistance: Tested to EN 50525-2-21 (AD8 condition), it is designed for permanent submersion up to 800 meters, ensuring reliability in deep-water environments.

Chemical and Abrasion Resistance: The elastomeric sheath protects against harsh chemicals and physical wear, ideal for mining and industrial settings.

Flexibility: The Class 5 tinned copper conductor allows for easy installation in confined or dynamic environments.

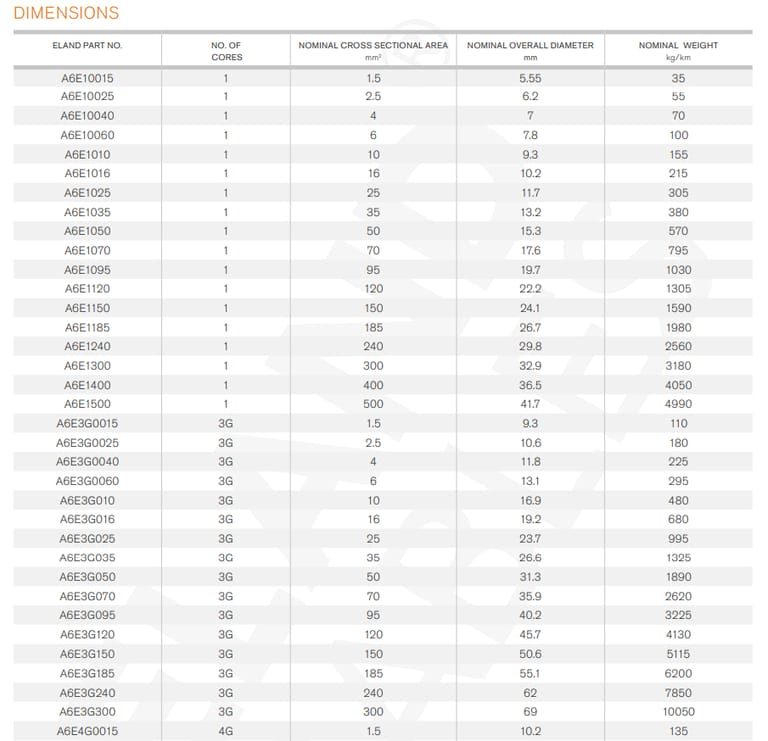

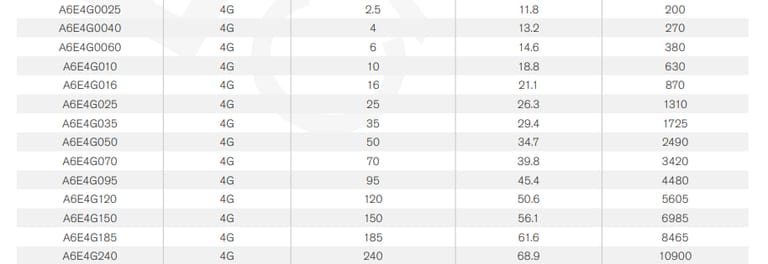

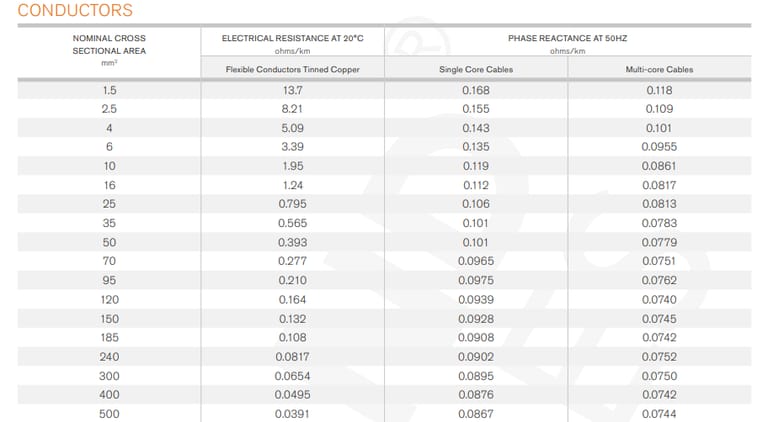

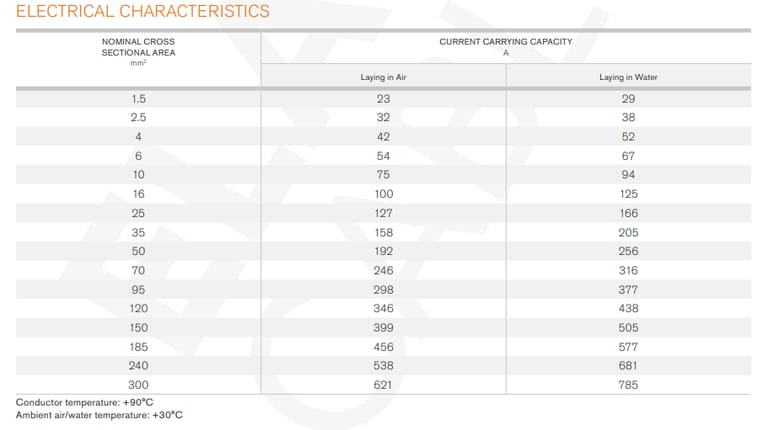

High Current Capacity: With capacities up to 785 A in water for 300 mm² cables, it supports high-power applications like submersible pumps.

Versatility: Suitable for diverse applications, from drinking water systems to swimming pool lighting and food processing systems.

Durability: The EPR insulation and cross-linked sheath ensure long-term performance in extreme temperatures and corrosive environments.

Usage Scenarios

The Drincable 800’s robust design makes it ideal for a range of applications:

Submersible Pumps in Mining: In South Africa’s mining sector, where deep underground water extraction is common, the Drincable 800 powers submersible pumps, ensuring reliable operation in abrasive and chemically aggressive environments.

Potable Water Systems: Its WRAS approval makes it perfect for drinking water extraction and treatment systems, ensuring no contamination.

Depuration and Chlorination Systems: Used in water purification plants to power equipment in submerged conditions.

Swimming Pool Lighting: Provides safe, reliable power for underwater lighting systems.

Aquariums and Food Processing: Ensures safe operation in wet environments where hygiene is critical.

Frequently Asked Questions

1. What makes the Drincable 800 suitable for potable water applications?

The Drincable 800 is WRAS-approved, ensuring it meets strict safety standards for potable water. Its EPR insulation and elastomeric sheath prevent contamination, while its AD8 water resistance allows reliable operation at depths up to 800 meters.

2. Can the Drincable 800 be used in extreme temperatures?

Yes, it operates between -25°C and +90°C, with a maximum water temperature of +80°C, making it suitable for diverse climates, including South Africa’s variable conditions.

3. How does the Drincable 800 perform in mining applications?

Its tinned copper conductors and abrasion-resistant sheath ensure durability in harsh mining environments, while its high current capacity supports powerful submersible pumps.

4. What are the bending radius requirements for installation?

The cable requires a minimum bending radius of 3x overall diameter when fixed and 5x overall diameter when flexed, ensuring flexibility without compromising integrity.

5. Is the Drincable 800 compliant with international standards?

Yes, it meets IEC 60811-2-1, EN 50525-2-21, EN 50363-1, IEC/EN 60228, KTW, DVGW W270, and DM174/04, ensuring global reliability.

The Drincable 800 is a testament to the advancements in cable technology, offering unparalleled performance in submersible applications. Its robust construction, compliance with international standards, and versatility make it a vital component in industries ranging from mining to water treatment. In South Africa, where water scarcity, sustainable mining, and reliable infrastructure are pressing concerns, the Drincable 800 provides a reliable solution. Whether powering submersible pumps in deep mines or ensuring safe drinking water, this cable is poised to play a critical role in the nation’s future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430