Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

EASYFLEX (N)7YRDGOEU Cable for Simple Reeling Application

The Feichun EASYFLEX (N)7YRDGOEU Cable: For Reeling Applications in South Africa's Mining and Heavy Industries

EASYFLEX (N)7YRDGOEU Cable for Simple Reeling Application

Understanding Cable Types: What Makes Reeling Cables Unique?

Reeling cables are a specialized category of power and control cables engineered for applications involving continuous winding and unwinding on reels, such as in cranes, excavators, and conveyor systems. Unlike standard fixed-installation cables, reeling cables must withstand dynamic stresses like bending, torsion, and tensile loads without compromising performance.

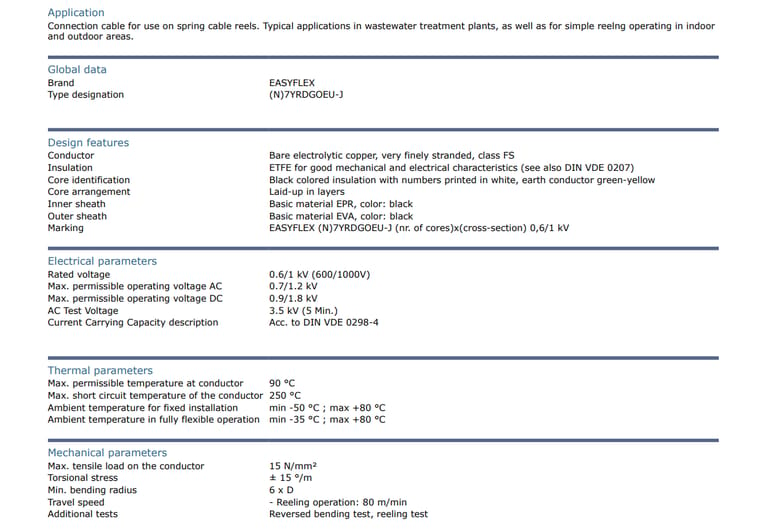

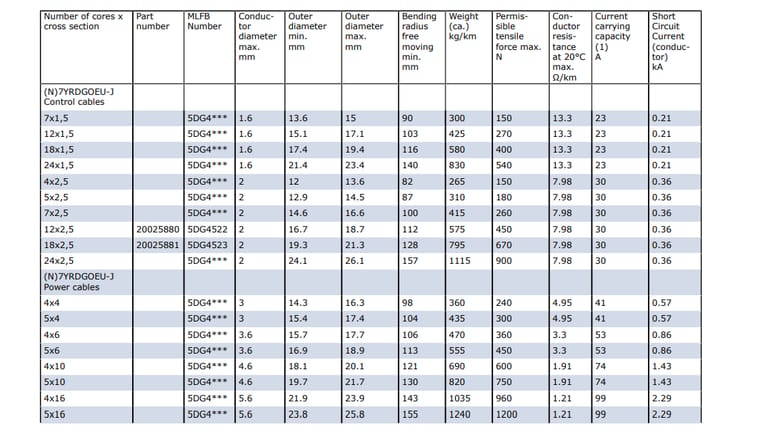

Feichun EASYFLEX (N)7YRDGOEU falls under the category of flexible reeling cables, designated as (N)7YRDGOEU-J. This type is optimized for simple reeling operations in both indoor and outdoor settings. It comes in two main variants: control cables (e.g., 7x1.5 to 24x2.5 mm²) and power cables (e.g., 4x4 to 5x16 mm²), allowing for versatile use in signal transmission or high-power delivery.

Key to its design is the conductor material: bare electrolytic copper, very finely stranded in Class FS configuration. This ensures high conductivity while providing the mechanical flexibility needed for repetitive motion. Insulation uses ETFE (Ethylene Tetrafluoroethylene), a fluoropolymer known for its exceptional resistance to chemicals, heat, and mechanical abrasion. The inner sheath is made of EPR (Ethylene Propylene Rubber) for added protection, while the outer sheath employs EVA (Ethylene-Vinyl Acetate) for superior abrasion, oil, and flame resistance.

Compared to traditional rubber-sheathed cables, the EASYFLEX (N)7YRDGOEU offers enhanced environmental resilience, making it ideal for harsh conditions prevalent in South African mines, where dust, moisture, and explosive atmospheres pose constant threats.

Why Choose the EASYFLEX (N)7YRDGOEU?

The benefits of the Feichun EASYFLEX (N)7YRDGOEU cable extend beyond its specs, offering tangible advantages in durability, efficiency, and cost savings.

First, its ETFE insulation and EVA outer sheath provide superior resistance to abrasion, oil, flames, and environmental stressors, outperforming competitors' standard rubber materials. This translates to longer service life and reduced downtime – a critical factor in industries where every minute of operation counts.

Second, the cable's high flexibility supports dynamic reeling systems, minimizing wear during continuous movement. In comparative terms, while competitors offer moderate durability, the EASYFLEX excels in high-speed reeling up to 80 m/min, ideal for automation and construction.

Third, electrical reliability ensures safe performance under extreme conditions, with low conductor resistance (e.g., 13.3 Ω/km for 1.5 mm²) and high short-circuit currents (up to 2.29 kA for 16 mm²).

Environmentally, its robust design reduces maintenance needs, aligning with sustainability trends in 2025's mining sector. For South African operations facing energy crises, this cable's efficiency helps optimize power usage, mitigating the impact of outages.

Overall, users report reduced maintenance costs and enhanced operational excellence, making it a smart investment for demanding applications.

Usage Scenarios and Case Studies: Real-World Impact in South Africa

The Feichun EASYFLEX (N)7YRDGOEU cable shines in scenarios requiring robust reeling, such as wastewater treatment plants, dynamic cable systems, and outdoor installations.

In wastewater treatment, it handles continuous reel movements in harsh, moist environments. For dynamic systems, its flexibility supports high-speed operations in cranes and conveyors. Outdoors, it resists temperature fluctuations and damage.

Focusing on South Africa, the mining industry – a cornerstone of the economy – is navigating 2025's challenges like energy shortages, political instability, and the shift to critical minerals for the energy transition. Reeling cables are vital for powering excavators, drills, and draglines in opencast and underground mines, where poor cable management can lead to safety issues and production halts.

Case Study 1: Addressing Energy Crises in Platinum Mining

In the Rustenburg platinum belt, a major mine operated by a leading South African firm faced frequent power outages in early 2025, exacerbated by national grid instability. Traditional cables in their reeling systems for electric shovels often failed under tensile stress and heat, causing downtime costing thousands per hour.

Switching to the Feichun EASYFLEX (N)7YRDGOEU, the mine integrated 4x10 mm² power cables into their excavator reels. The cable's 90°C conductor tolerance and 15 N/mm² tensile strength ensured reliable power delivery during outages, allowing seamless integration with backup generators. Result? Downtime reduced by 40%, aligning with industry calls for modernization as highlighted in recent reports on South Africa's energy transition. This not only boosted productivity but also supported the extraction of platinum group metals critical for green technologies.

Case Study 2: Enhancing Safety in Coal Mining Amid Environmental Challenges

A coal mine in Mpumalanga, dealing with explosive atmospheres from methane and dust – a common 2025 challenge per mining safety studies – struggled with abrasion on trailing cables for conveyor systems. Incidents of cable failures led to safety risks and regulatory scrutiny.

Implementing 18x1.5 mm² control cables from the EASYFLEX line, the mine benefited from the EVA sheath's abrasion resistance and ETFE's mechanical strength. At reeling speeds of 60 m/min, the cables endured torsional stress without fraying, reducing accident risks. This case echoes broader trends in African mining, where political and regulatory shifts demand safer, more reliable infrastructure. The mine reported a 30% drop in maintenance costs and improved compliance, contributing to sustainable operations amid global coal demand fluctuations.

These examples underscore how the EASYFLEX (N)7YRDGOEU addresses current issues, from energy efficiency to safety in heavy industries.

Frequently Asked Questions (FAQ)

Q: What makes the EASYFLEX (N)7YRDGOEU suitable for mining? A: Its ETFE insulation and EVA sheath provide resistance to abrasion, chemicals, and extremes, ideal for dynamic reeling in mines.

Q: Can it handle South Africa's power fluctuations? A: Yes, with a rated voltage of 0.6/1 kV and high test voltage, it ensures stable performance during outages.

Q: How does it compare to standard cables? A: It offers superior flexibility and durability, with optimized materials for reeling speeds up to 80 m/min.

Q: What core sizes are available? A: Control: 7x1.5 to 24x2.5 mm²; Power: 4x4 to 5x16 mm².

Q: Is it flame-resistant? A: Yes, the EVA outer sheath provides excellent flame resistance.

Q: How do I contact Feichun for custom solutions? A: Visit their website or reach out via customer support for tailored reeling cable needs.

Feichun EASYFLEX (N)7YRDGOEU cable represents the forefront of cable technology, blending innovation with practicality for reeling applications. In South Africa's mining and heavy industries, where 2025 brings energy transitions and operational hurdles, this cable delivers reliability, efficiency, and safety. By understanding its specs, benefits, and real-world uses, industries can unlock new levels of performance. As Feichun continues to lead in industrial solutions, embracing such advancements ensures a resilient future.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430