Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Feichun NGFLGOEU Low Voltage Flat Cable for Festoon Application

Feichun NGFLGOEU: A Flexible Low Voltage Flat Cable Designed for Festoon Systems in Demanding Industrial Applications

PLANOFLEX NGFLGOEU Low Voltage Flat Cable for Festoon Application

Technical Excellence of PLANOFLEX NGFLGOEU

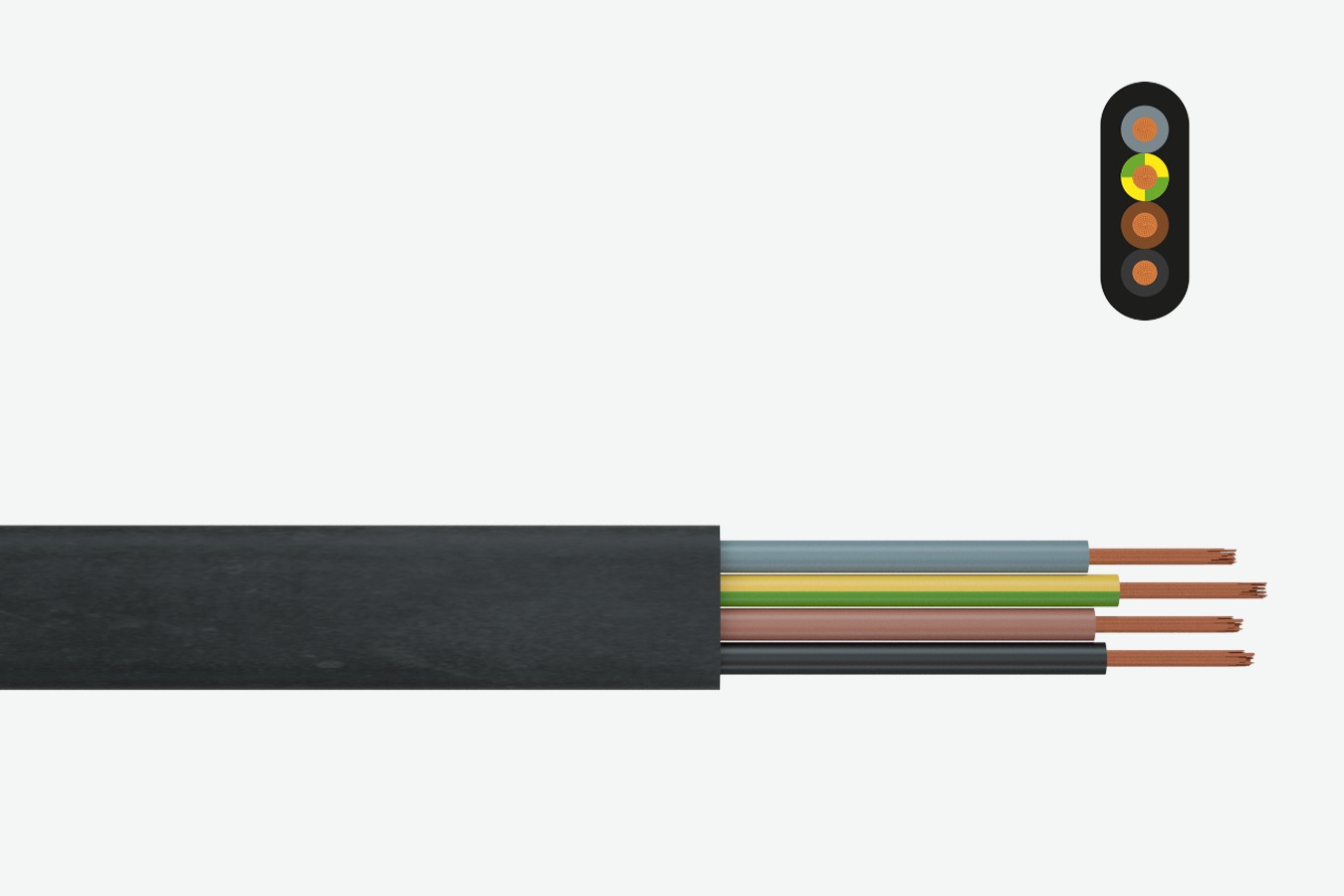

Design and Construction

The PLANOFLEX NGFLGOEU is a flat cable designed with precision to meet the rigorous demands of industrial applications. Its construction balances flexibility with durability, ensuring it can handle high mechanical stresses while maintaining excellent electrical performance.

Conductor Composition: Made from high-purity electrolytic copper, the conductors are either Class 5 (finely stranded for cross-sections above 35 mm²) or Class 6 (extremely finely stranded for up to 25 mm²), as per DIN VDE 0295. This ensures exceptional flexibility for dynamic applications.

Insulation Material: The cable uses PROTOLON EPR (Ethylene Propylene Rubber), a robust rubber compound (3GI3 per DIN VDE 0207, Part 20) that provides superior electrical insulation and resistance to environmental stressors.

Sheathing Material: A halogen-free, heavy-duty CR (Chloroprene Rubber) compound (5GM3 per DIN VDE 0207, Part 21) forms the outer sheath, offering protection against mechanical wear and environmental hazards.

Shielding: A tinned copper wire braided screen provides EMC (Electromagnetic Compatibility) shielding, with approximately 60% coverage for shielded cores and 80% for twisted pairs, ensuring stable performance in high-interference environments.

Core Arrangement: The flat design features parallel cores or bundled configurations for higher core counts, optimized for bending in one plane, which is ideal for festoon systems.

This construction makes the PLANOFLEX NGFLGOEU a versatile choice for applications requiring both flexibility and resilience.

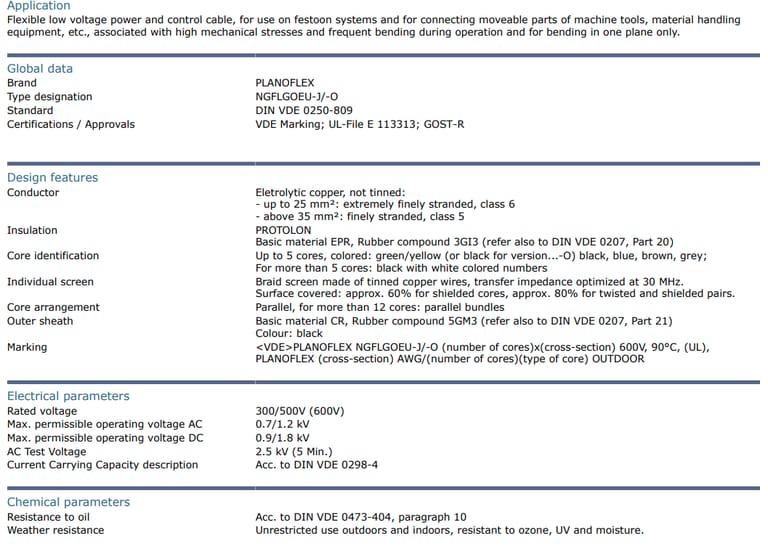

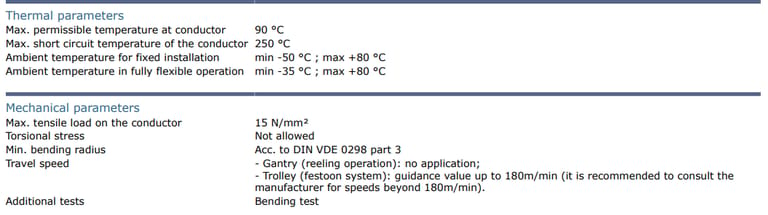

Electrical Performance

The PLANOFLEX NGFLGOEU is engineered for reliable power delivery in low voltage applications. Its electrical specifications include:

Rated Voltage: 300/500 V (up to 600 V in some configurations).

Maximum Operating Voltage: AC 0.7/1.2 kV; DC 0.9/1.8 kV.

Voltage Withstand: Up to 2.5 kV for 5 minutes, ensuring robust insulation.

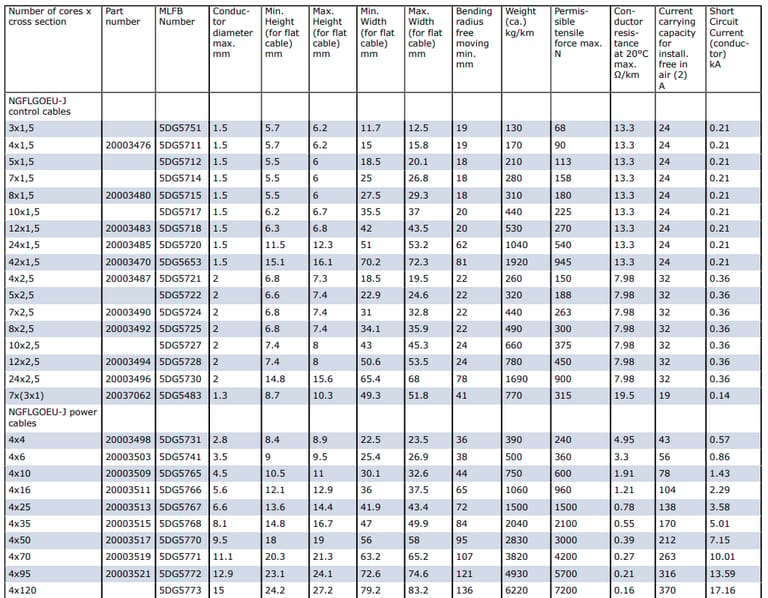

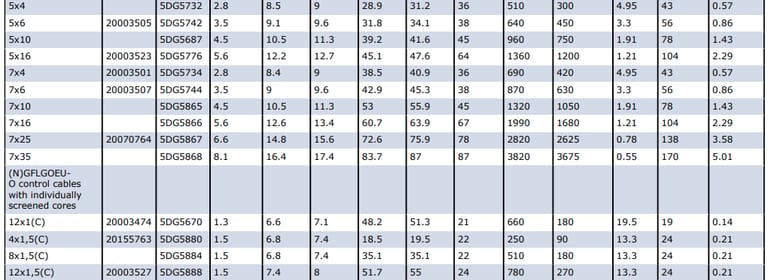

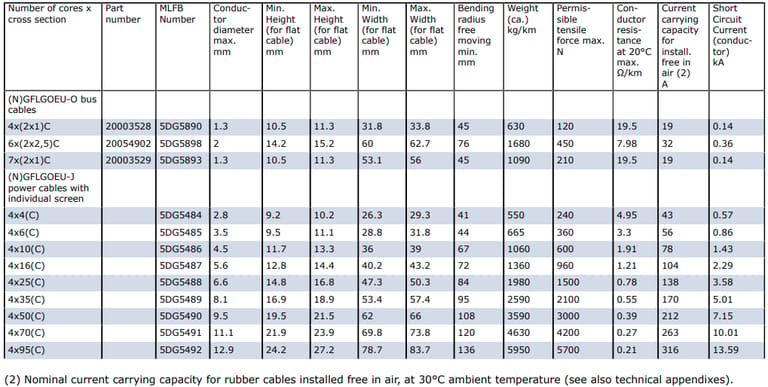

Current Carrying Capacity: Optimized per DIN VDE 0298-4, with capacities ranging from 19 A for smaller cross-sections (e.g., 12x1 mm²) to 370 A for larger ones (e.g., 4x120 mm²) when installed free in air at 30°C.

These specifications ensure the cable can handle the power demands of heavy machinery while maintaining safety and efficiency.

Environmental and Mechanical Resilience

Industrial environments, particularly in South Africa’s mining sector, expose cables to extreme conditions—oil, UV radiation, moisture, and mechanical stress. The PLANOFLEX NGFLGOEU is built to thrive in such settings:

Chemical Resistance:

Oil Resistance: Compliant with DIN VDE 0473-404, making it suitable for environments with oil exposure, such as mining equipment.

UV Protection: Designed for unrestricted indoor and outdoor use, withstanding prolonged sunlight exposure without degradation.

Ozone and Moisture Resistance: Offers exceptional protection against ozone and water, ensuring long-term durability.

Thermal Performance:

Operating Temperature: From -35°C to +80°C in fully flexible operation, and -50°C to +80°C for fixed installations.

Short-Circuit Temperature: Up to 250°C, providing safety during fault conditions.

Mechanical Strength:

Tensile Load Capacity: Supports up to 15 N/mm², ensuring durability under mechanical stress.

Minimum Bending Radius: As low as 7x cable diameter, allowing tight bends in dynamic festoon systems.

Travel Speed: Suitable for festoon systems with speeds up to 180 m/min (consult manufacturer for higher speeds).

These features make the PLANOFLEX NGFLGOEU a reliable choice for harsh industrial environments.

Applications in Industrial Settings

The PLANOFLEX NGFLGOEU’s versatility makes it indispensable across various industrial applications, particularly in festoon systems where cables must endure frequent bending and movement. Key use cases include:

Machine Tool Connections: The cable’s flexibility and durability ensure reliable performance in high-speed, repetitive movements, such as in CNC machines or robotic arms.

Material Handling Equipment: Ideal for cranes, hoists, and conveyors, the cable provides stable power transmission in constantly moving systems.

Movable Part Interconnections: Perfect for automated systems requiring flexible, durable connections, such as in automated warehouses or assembly lines.

Installation and Maintenance Best Practices

To maximize the performance and lifespan of PLANOFLEX NGFLGOEU cables, adhere to these guidelines:

Mounting: Avoid sharp bends and maintain the recommended minimum bending radius (7x cable diameter for free-moving applications). Use proper festoon system guides to prevent overstretching.

Environmental Protection: In abrasive or chemically aggressive environments, such as those with heavy oil or acid exposure, add protective sleeves or conduits to enhance durability.

Regular Inspections: Conduct periodic checks for wear and tear, especially in high-movement applications, to prevent premature failure.

EMI Mitigation: For applications with high electromagnetic interference, opt for screened variants to ensure signal integrity.

Troubleshooting Common Issues

Electromagnetic Interference (EMI): If signal noise disrupts system functionality, use screened cables (e.g., 4x4(C) or 12x1,5(C)) for enhanced EMI protection.

Environmental Wear: Prolonged exposure to oils or UV can degrade cable life. Apply protective conduits or select variants with higher chemical resistance.

Mechanical Stress: Overstretching or improper bending can cause conductor fatigue. Ensure correct installation practices and adhere to tensile load limits (15 N/mm²).

Conclusion

Feichun PLANOFLEX NGFLGOEU is a game-changer for industrial applications requiring flexible, durable, and high-performance low voltage cables. Its robust design, featuring high-purity copper conductors, PROTOLON EPR insulation, halogen-free CR sheathing, and EMC shielding, ensures reliability in demanding festoon systems. From South Africa’s mining sector to global industrial applications, this cable delivers unmatched performance, as evidenced by its success in gold and platinum mining operations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430