Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Feichun PROTOMONT (Z) NSSHKCGEOEU Coal Cutter Cables for Trailing Operation

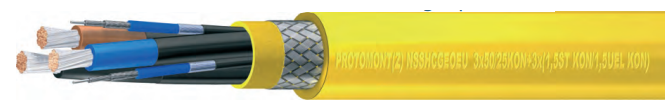

PROTOMONT (Z) NSSHKCGEOEU 0.6/1kV Coal Cutter Cable: Engineered for Trailing Operations in Mobile Mining Equipment

Feichun PROTOMONT (Z) NSSHKCGEOEU Coal Cutter Cables for Trailing Operation

Application | Usage | Power supply connection cable for mobile equipment in underground machine applications (e.g., coal shearer, roadheader, TBMs, scoops/LHDs). Designed for free trailing operation, suitable for considerable trailing distances. |

Global Data | Brand | Feichun PROTOMONT(Z) |

Type Designation | NSSHKCGEOEU | |

Standard | DIN VDE 0250-812 | |

Certifications/Approvals | MSHA P-189-4, BAS Bosnia-Herzegovina, Fire Certificate of Russian Federation, TR-Certificate, GOST K, GOST B | |

Design Features | Conductor | Very finely stranded copper conductor, tinned (class FS) |

PE-Conductor | 3 double-concentric control/PE wire spinning in the outer interstice | |

Insulation | PROTOLON, Basic material: EPR, Compound type: 3GI3 | |

Core Identification | Main cores: Colored (Black, Grey, Brown); Control cores: Blue | |

Core Arrangement | Three main conductors laid-up, with double-concentric control/PE conductor elements in the outer interstice, length of lay approx. 6 x D | |

Inner Sheath | Vulcanized rubber inner sheath, Basic material: EPR, Compound type: GM1B | |

Armouring | Braid of steel/copper wires in a vulcanized bond between inner and outer sheath | |

Outer Sheath | PROTOFIRM, Basis: synthetic elastomer compound (e.g., CM), Compound type: 5GM5, Color: Yellow | |

Electrical Parameters | Rated Voltage | 0.6/1 kV (600/1000V) |

Max. Permissible Operating Voltage AC | 0.7/1.2 kV | |

Max. Permissible Operating Voltage DC | 0.9/1.8 kV | |

AC Test Voltage | 3 kV | |

AC Test Voltage - Control Cores | 2 kV | |

Chemical Parameters | Resistance to Fire | EN 60332-1-2, IEC 60332-1-2 |

Resistance to Oil | EN 60811-404, IEC 60811-404 | |

Weather Resistance | Unrestricted use outdoors and indoors, resistant to ozone and moisture | |

Thermal Parameters | Max. Permissible Temperature at Conductor | 90 °C |

Max. Short Circuit Temperature of the Conductor | 250 °C | |

Ambient Temperature for Fixed Installation (Min.) | -40 °C | |

Ambient Temperature for Fixed Installation (Max.) | 80 °C | |

Ambient Temperature in Fully Flexible Operation (Min.) | -20 °C | |

Ambient Temperature in Fully Flexible Operation (Max.) | 60 °C | |

Mechanical Parameters | Max. Tensile Load of Cable | 40 N/mm² |

Minimum Breaking Load of Steel Braid | 45 kN | |

Torsional Stress | 25 °/m | |

Travel Speed | 150 m/min |

Number of cores x cross section | Conductor diameter max. (mm) | Outer diameter min. (mm) | Outer diameter max. (mm) | Net weight approx. (kg/km) | Permissible tensile force max. (N) | Breaking load of the braid (kN) | Conductor resistance at 20°C max. (Ω/km) | Nom. operating capacitance (µF/km) | Inductance nom. (mH/km) | Current carrying capacity (1) (A) | Short Circuit Current (conductor) (kA) |

|---|---|---|---|---|---|---|---|---|---|---|---|

3x25+3x(1,5STKON+16/3KON) | 7.1 | 39.2 | 42.2 | 2700 | 3000 | 45 | 0.795 | 0.37 | 0.33 | 131 | 3.58 |

3x35+3x(1,5STKON+16/3KON) | 8.4 | 40.8 | 43.8 | 3100 | 4200 | 45 | 0.565 | 0.42 | 0.3 | 162 | 5.01 |

3x50+3x(1,5STKON+25/3KON) | 10.1 | 46.2 | 49.2 | 4000 | 6000 | 45 | 0.393 | 0.45 | 0.28 | 202 | 7.15 |

3x70+3x(1,5STKON+35/3KON) | 11.9 | 49.6 | 53.6 | 5100 | 8400 | 45 | 0.277 | 0.52 | 0.27 | 250 | 10.01 |

3x95+3x(1,5STKON+50/3KON) | 14 | 56.8 | 60.8 | 6700 | 11400 | 45 | 0.21 | 0.55 | 0.27 | 301 | 13.59 |

3x120+3x(1,5STKON+70/3KON) | 15.5 | 60.6 | 64.6 | 8000 | 14400 | 45 | 0.164 | 0.59 | 0.26 | 352 | 17.16 |

3x150+3x(1,5STKON+70/3KON) | 17.6 | 67 | 71 | 9600 | 18000 | 45 | 0.132 | 0.61 | 0.26 | 404 | 18.3 |

3x185+3x(1,5STKON+95/3KON) | 19.1 | 72 | 76 | 11500 | 22200 | 45 | 0.108 | 0.63 | 0.26 | 461 | 26.46 |

3x240+3x(1,5STKON+120/3KON) | 22 | 80.4 | 85.4 | 14600 | 28800 | 45 | 0.0817 | 0.67 | 0.25 | 544 | 34.32 |

3x300+3x(1,5STKON+150/3KON) | 24.8 | 89.1 | 94.1 | 18700 | 36000 | 45 | 0.0654 | 0.7 | 0.25 | 626 | 42.9 |

Introduction

In the depths of the Earth, where darkness reigns and machinery battles against rock and ore, reliable power transmission is not just a convenience—it's a lifeline. Underground mining operations demand equipment that can endure extreme conditions: crushing pressures, abrasive surfaces, moisture-laden air, and constant movement. Enter the PROTOMONT (Z) NSSHKCGEOEU 0.6/1kV coal cutter cable, a marvel of modern cable technology engineered specifically for trailing operations in mobile mining equipment. This cable, designed by Feichun, stands as a testament to how advanced materials and precise engineering can transform hazardous environments into safer, more productive workspaces.

Usage Scenarios: Powering the Heart of Underground Mining

The PROTOMONT (Z) NSSHKCGEOEU coal cutter cables shine in free trailing operations, where cables are dragged behind mobile equipment over extended distances in tunnels. Primary applications include:

Coal Shearers: These machines slice through coal seams, requiring cables that flex with the shearer's arm movements while resisting coal dust abrasion.

Roadheaders: Used for excavating tunnels, roadheaders pivot and boom, demanding cables with high torsional tolerance to avoid kinking.

Tunnel Boring Machines (TBMs): In large-scale tunneling, TBMs advance steadily, trailing cables that must handle continuous pulling and environmental exposure.

Load-Haul-Dump (LHD) Vehicles: Scoops that load and transport ore need cables for powering hydraulic systems, enduring impacts from falling debris.

In these scenarios, the cable's design ensures uninterrupted power, reducing downtime in operations where every minute counts. Its flexibility allows for considerable trailing distances, essential in narrow, winding mine shafts.

Common Challenges and Feichun's Innovative Solutions

Underground mining is fraught with perils that can doom lesser cables. Here's an in-depth look at key challenges and how the PROTOMONT (Z) addresses them.

Cable Damage from Mechanical Stress: Extreme bending, torsion, and abrasion are rampant. Without proper design, cables fray, leading to shorts or breaks.

Feichun Solution: The steel-copper braid armoring and EPR insulation provide superior durability. The fine-stranded conductors and short lay length minimize internal stress, allowing the cable to endure 25°/m torsion and 150 m/min speeds.

Environmental Factors: Moisture, oil, extreme temperatures (-40°C to 90°C), and UV exposure degrade materials over time.

Feichun Solution: The flame-retardant PROTOFIRM outer sheath resists oils and UV, while EPR insulation maintains integrity in wet, hot, or cold conditions. Ozone and moisture resistance ensure longevity.

Electrical Failures: Poor grounding or connections cause hazards like arcs or downtime.

Feichun Solution: Double-concentric PE/control conductors enhance grounding, and compliance with BS6708 ensures stable transmission. Multi-layered design prevents voltage drops.

These solutions not only mitigate risks but also extend cable life, cutting replacement costs.

Compliance with International Standards

Safety is paramount, and the PROTOMONT (Z) meets rigorous benchmarks:

EN/IEC 60332-1-2: For flame retardancy, preventing fire spread.

BS6708: Tailored for flexible mining trailing cables.

MSHA Certification: U.S. Mine Safety and Health Administration approval for hazardous areas.

Additional nods from Russian Fire Certificates and TR/GOST ensure global applicability, guaranteeing performance in explosive atmospheres.

Best Practices for Installation and Maintenance

To harness the full potential of these coal cutter cables:

Pre-Installation Inspection: Check for defects; verify suitability.

Bending Radius Compliance: Maintain at least 6xD to protect insulation.

Stress Minimization: Avoid excessive pulling; use guides for trailing.

Regular Diagnostics: Visual inspections and electrical tests catch issues early.

Timely Replacement: Swap out damaged sections to prevent failures.

Adhering to these extends service life and bolsters safety.

Case Study: Enhancing Efficiency in South Africa's Deep-Level Gold Mines

South Africa's mining industry, particularly in the Witwatersrand Basin, exemplifies the PROTOMONT (Z)'s real-world impact. In 2023, a major gold mine operator near Johannesburg faced recurrent cable failures in their roadheader fleet, leading to 15% downtime and safety concerns from exposed conductors.

Switching to PROTOMONT (Z) NSSHKCGEOEU cables, the mine integrated them into trailing operations for roadheaders excavating at depths over 2,000 meters. The cables' steel braiding withstood abrasive quartzite rock, while EPR insulation resisted humidity levels exceeding 90%. Over six months, downtime dropped by 40%, with no electrical failures reported. The MSHA-compliant design aligned with South Africa's stringent MHSA regulations, and the yellow sheath improved visibility in dimly lit shafts.

Engineers noted the cable's 150 m/min travel speed matched the roadheaders' pace, allowing seamless extension of tunnels. This case underscores how tailored cable technology can boost productivity in Africa's challenging geology, where heat and depth amplify stresses.

Frequently Asked Questions

What makes the PROTOMONT (Z) NSSHKCGEOEU suitable for trailing operations?

Its fine-stranded conductors, steel braiding, and short lay length enable flexibility and durability for long-distance dragging behind equipment.

How does it handle extreme temperatures?

With a conductor max of 90°C and ambient ranges from -40°C to 80°C, it's built for variable mine conditions.

Is it oil-resistant?

Yes, per EN 60811-404, protecting against hydraulic fluids common in mining.

What certifications does it hold?

MSHA, BS6708, EN/IEC 60332-1-2, and various GOST approvals.

Can it be used outdoors?

Absolutely, with UV and weather resistance for unrestricted use.

How often should it be inspected?

Regularly, as per best practices—visual checks monthly, electrical tests quarterly.

The PROTOMONT (Z) NSSHKCGEOEU 0.6/1kV coal cutter cable for trailing operation represents a pinnacle in cable technology, blending advanced materials like EPR and steel braiding with precise engineering to conquer underground mining's harshest challenges. From powering coal shearers in confined tunnels to enabling efficient TBM advances, it ensures reliable energy transmission while prioritizing safety through global certifications.

As mining evolves toward sustainability and automation, cables like this will play a crucial role. By adopting best practices and learning from cases like South Africa's gold mines, operators can minimize risks and maximize output. For those in the industry, Feichun's engineering team offers tailored support—proving that in the world of underground mining, the right cable isn't just a component; it's the backbone of success.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430