Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Feichun (N)GRDGCGOEU Low Voltage Screened Round Cable for Festoon Application

(N)GRDGCGOEU Low-voltage Screened Round Cable for Festoon Applications, Featuring Advanced Electromagnetic Compatibility (EMC)

(N)GRDGCGOEU Low Voltage Screened Round Cable for Festoon Application

The Science Behind the Cable: Electromagnetic Compatibility and Beyond

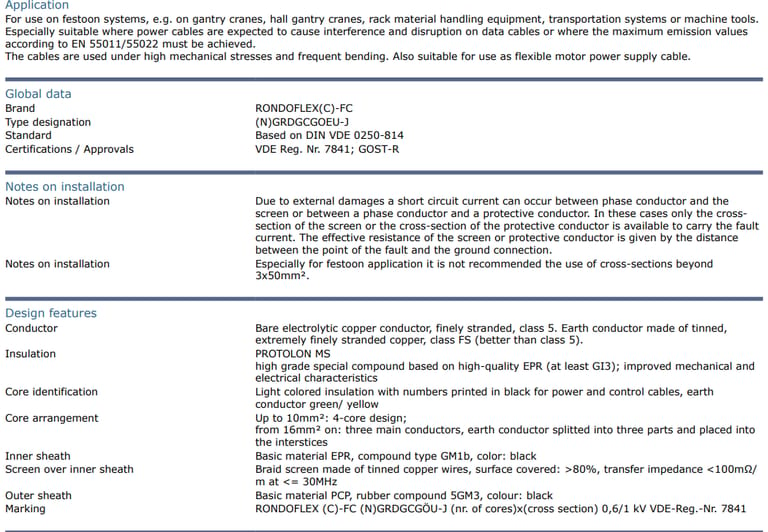

At its core, the RONDOFLEX(C)-FC (N)GRDGCGOEU is a low-voltage screened cable rated at 0.6/1 kV (600/1000V), optimized for festoon systems. Festoon applications involve cables that loop and move dynamically, supporting power and data transmission in mobile equipment like gantry cranes, hall material handling systems, and machine tools. What sets this cable apart is its advanced EMC shielding, which minimizes EMI—a common culprit in industrial disruptions.

EMI occurs when electromagnetic fields from one device interfere with another, causing signal degradation, equipment malfunctions, or even safety hazards. In environments with variable frequency drives (VFDs)—devices that control motor speed for energy efficiency—EMI can spike due to high-frequency switching. The RONDOFLEX(C)-FC addresses this with a braid screen of tinned copper wires offering over 80% surface coverage and a transfer impedance below 100 mΩ/m at frequencies up to 30 MHz. This shielding ensures peak voltage handling up to 2400V while maintaining EMC performance, complying with standards like EN 55011/55022 for emission limits.

The cable's conductor engineering is equally impressive. Main conductors are bare electrolytic copper, finely stranded to Class 5 for high flexibility, while the earth conductor uses tinned copper in Class FS (superior to Class 5) for enhanced corrosion resistance and conductivity. Insulation is based on PROTOLON MS, a high-grade ethylene propylene rubber (EPR) compound with superior mechanical and electrical properties, rated GI3 or better. This setup allows for a core arrangement that optimizes space: four-core design up to 10mm², transitioning to three main conductors with a split earth in interstices for larger cross-sections.

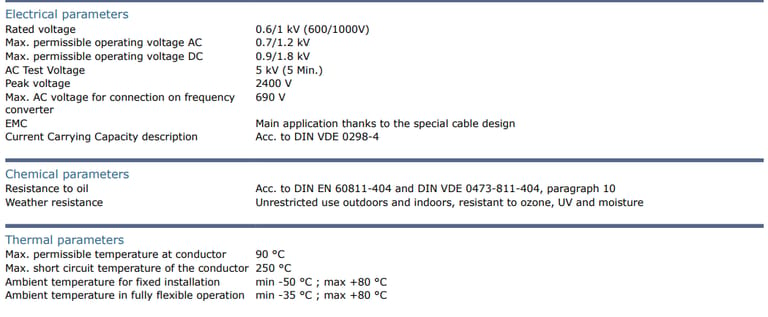

Electrically, the cable supports maximum permissible voltages of AC 0.7/1.2 kV and DC 0.9/1.8 kV, with an AC test voltage of 5 kV for five minutes. It's tailored for frequency converter applications, handling up to 690V AC in VFD setups without compromising current carrying capacity. Thermal resilience is key: it operates from -50°C to +80°C in fixed installations and -35°C to +80°C in flexible use, with a conductor temperature limit of 90°C and short-circuit tolerance up to 250°C.

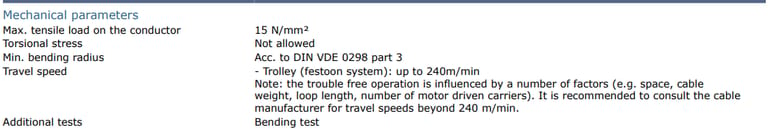

Mechanically, the cable withstands tensile loads up to 15 N/mm² and travel speeds of 240 m/min in festoon systems, adhering to DIN VDE 0298 for bending radii. Its outer sheath, made from polychloroprene (PCP) rubber compound 5GM3, provides oil resistance per DIN EN 60811-404, along with ozone, UV, and moisture protection. Additional tests, like bending cycles, confirm its durability under frequent stresses.

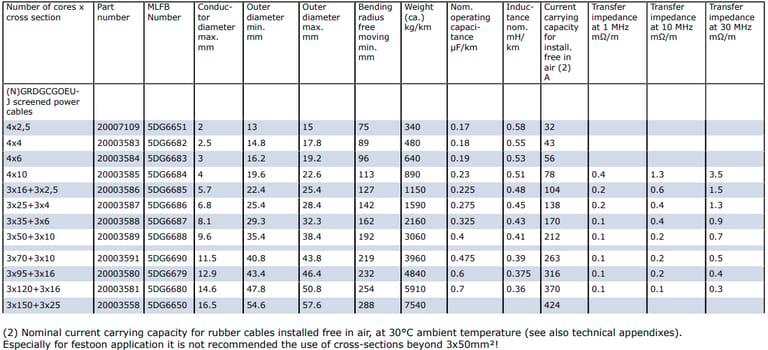

In essence, this cable blends physics and materials science: copper's conductivity reduces resistance losses, EPR insulation prevents dielectric breakdown, and the screened design leverages Faraday's cage principles to block EMI. Compared to standard cables, it offers lower inductance (around 0.4-0.7 mH/km) and capacitance (0.17-0.7 µF/km), ensuring stable signal integrity.

Applications: Where Durability Meets Demand

The RONDOFLEX(C)-FC shines in high-interference settings, such as gantry cranes on mining sites or automated transportation systems in factories. Its VFD compatibility makes it ideal for motor power supply in dynamic operations, where frequent bending could otherwise cause failures. In heavy industry, it's used to interconnect machine tools, ensuring data cables remain unaffected by power line noise.

Globally, festoon cables like this are crucial for reducing downtime. For instance, in rack material handling equipment, the cable's mechanical endurance prevents breakage during rapid movements, while EMC shielding safeguards against disruptions from nearby electronics.

Frequently Asked Questions

What makes the RONDOFLEX(C)-FC (N)GRDGCGOEU suitable for festoon applications? Its high-flex Class 5 conductors, minimal bending radius per DIN VDE 0298, and travel speed up to 240 m/min ensure it endures dynamic movements without fatigue.

How does it handle EMI in VFD systems? The tinned copper braid screen with >80% coverage and low transfer impedance (<100 mΩ/m at ≤30 MHz) blocks external interference, ensuring stable transmission in frequency converter setups.

Is it compliant with international standards? Yes, it's VDE registered (Reg. Nr. 7841), EAC certified, and based on DIN VDE 0250-814, with oil resistance per DIN EN 60811-404.

What cross-sections are available, and why limit beyond 3x50mm²? Options range from 4x2.5 to 3x150+3x25 mm². Larger sizes are not recommended for festoon due to weight and flexibility constraints, risking mechanical failure.

Can it be used outdoors in South Africa? Absolutely—its weather resistance to ozone, UV, and moisture, plus -50°C to +80°C range, suits the country's variable climates, from arid mines to coastal industries.

How does it compare to standard mining cables like Type 61A? While Type 61A excels in general underground power, the RONDOFLEX(C)-FC offers superior EMC for EMI-prone VFD applications, with better flexibility and shielding.

The Feichun RONDOFLEX(C)-FC (N)GRDGCGOEU isn't merely a product; it's a testament to engineering ingenuity, blending EMC shielding, mechanical resilience, and environmental toughness. In South Africa, where mining trends lean toward sustainability and automation, it addresses EMI challenges, reduces downtime, and enhances safety. As the global cables for mining market surges to $12,640 million in 2025 and festoon systems to $956.9 million, adopting such technology is key to competitiveness.

For engineers and procurement teams, the next steps are clear: Assess site-specific needs, consult datasheets, and integrate this cable for transformative results. In an era of industrial evolution, the RONDOFLEX(C)-FC empowers operations to thrive, proving that even the humblest components can drive monumental change.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430