Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Feichun (N)GRDGOEU/(N)GRDGCGOEU Low Voltage Cable for Energy Chains

(N)GRDGOEU/(N)GRDGCGOEU Low Voltage Cable: Enhancing Reliability and Performance in Energy Chains for Industrial Cranes and Material Handling Systems

(N)GRDGOEU/(N)GRDGCGOEU Low Voltage Cable for Energy Chains

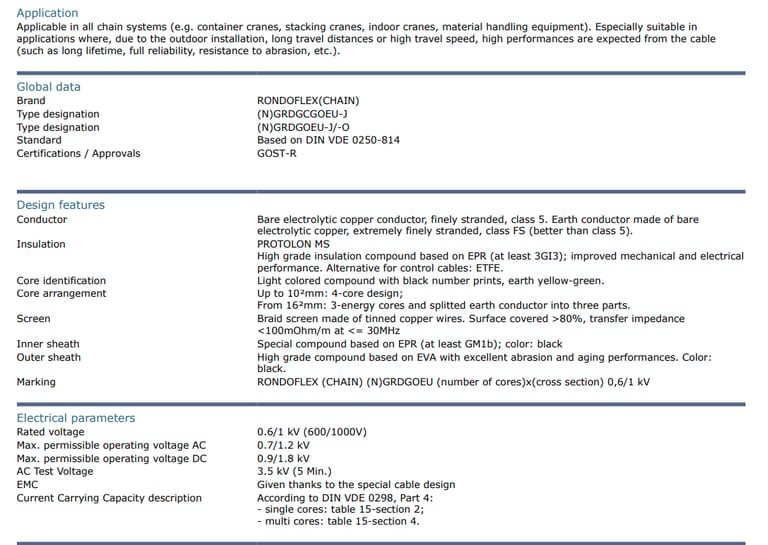

Understanding RONDOFLEX(CHAIN) (N)GRDGOEU/(N)GRDGCGOEU Low Voltage Cable

In the fast-paced world of industrial automation and heavy machinery, the backbone of reliable operation often lies in the unassuming yet critical components like cables. Enter the RONDOFLEX(CHAIN) (N)GRDGOEU/(N)GRDGCGOEU low voltage cable, a specialized engineering marvel designed specifically for energy chains in high-demand environments. This cable isn't just a wire; it's a testament to advanced materials science and electrical engineering, engineered to withstand the rigors of outdoor installations, long travel distances, and high-speed operations. Whether powering container cranes at bustling ports or stacking equipment in massive warehouses, this low voltage cable ensures seamless energy transmission, minimizing downtime and maximizing productivity.

At its core, the RONDOFLEX(CHAIN) series addresses a universal challenge in modern industry: the need for cables that can endure extreme mechanical stress while maintaining electrical integrity. Based on the DIN VDE 0250-814 standard and certified with GOST-R approvals, these cables are built for global applications, but they shine particularly in scenarios where reliability is non-negotiable. With rated voltages of 0.6/1 kV and exceptional resistance to abrasion, ozone, UV, and moisture, they represent a leap forward in cable technology for energy chains.

Design Features

The brilliance of the RONDOFLEX(CHAIN) (N)GRDGOEU/(N)GRDGCGOEU low voltage cable lies in its meticulously crafted design, which integrates high-grade materials to optimize performance in energy chains. Starting with the conductor, it's made from bare electrolytic copper, finely stranded to class 5 standards for flexibility. For the earth conductor, it's even finer—class FS, surpassing class 5 for enhanced bendability and durability. This stranding allows the cable to flex repeatedly without fatigue, crucial for the dynamic movements in energy chains.

Insulation is another standout feature. The PROTOLON MS compound, based on ethylene propylene rubber (EPR) rated at least 3GI3, provides superior mechanical and electrical properties. For control variants, ethylene tetrafluoroethylene (ETFE) is an alternative, offering chemical resistance and low friction. Cores are identified with light-colored compounds and black numbering, plus a yellow-green earth for easy installation. Arrangement varies by size: up to 10 mm² in a 4-core design, and from 16 mm² with three energy cores and a split earth conductor into three parts. This configuration minimizes electromagnetic interference and ensures balanced load distribution.

For screened versions like (N)GRDGCGOEU, a braid screen of tinned copper wires covers over 80% of the surface, with a transfer impedance below 100 mΩ/m at frequencies up to 30 MHz. This shielding is vital for electromagnetic compatibility (EMC), protecting against noise in sensitive industrial settings. The inner sheath, a special EPR-based compound (GM1b rating), is black and provides additional protection, while the outer sheath uses ethylene vinyl acetate (EVA) for exceptional abrasion resistance and aging performance, also in black.

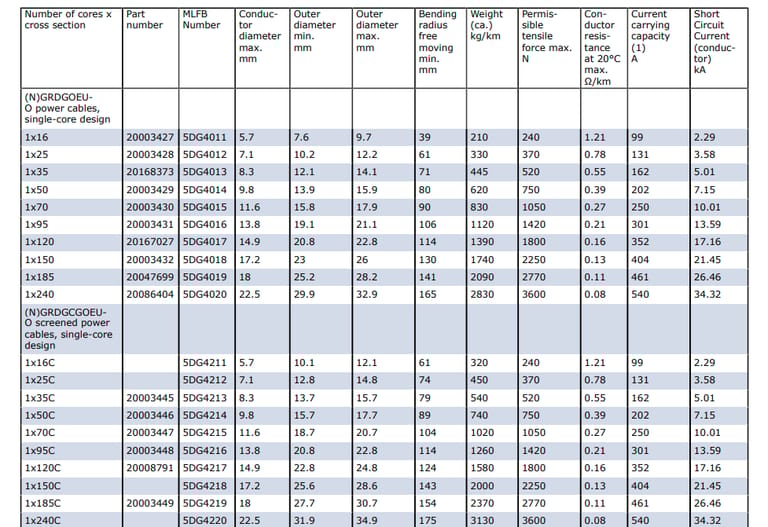

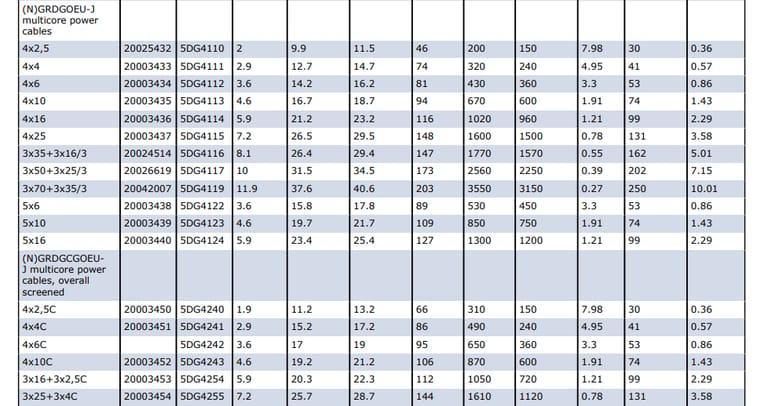

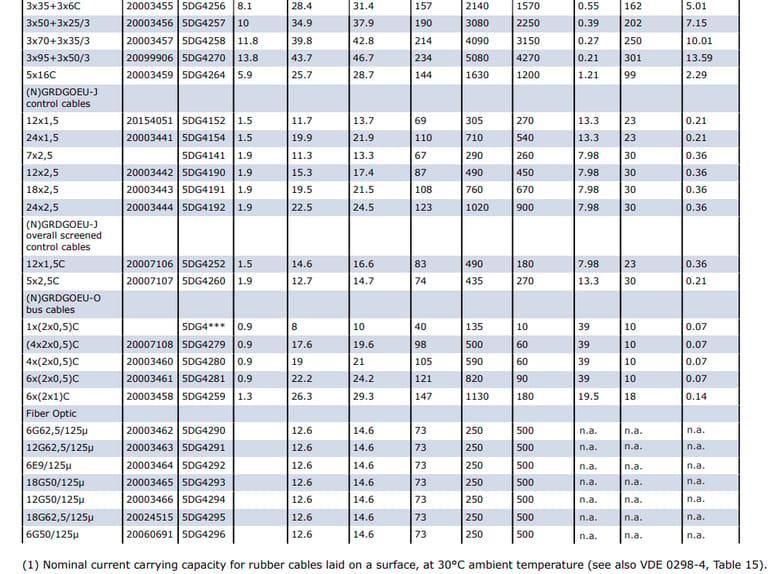

Marking on the cable reads "RONDOFLEX (CHAIN) (N)GRDGOEU (number of cores)x(cross section) 0,6/1 kV," ensuring traceability. Variants include single-core power cables, screened single-core, multicore power, control cables, bus cables, and even fiber optic options. For instance, the 1x16 mm² single-core has a conductor diameter of 5.7 mm, outer diameter from 7.6 to 9.7 mm, and weighs about 210 kg/km. These design elements collectively make the RONDOFLEX(CHAIN) a versatile powerhouse for energy chains, where cables must coil, uncoil, and travel extensively without failure.

Technical Specifications:

To appreciate the RONDOFLEX(CHAIN) (N)GRDGOEU/(N)GRDGCGOEU low voltage cable's prowess, let's break down its specifications across electrical, chemical, thermal, and mechanical parameters—each tailored for demanding energy chain applications.

Electrically, the cable operates at a rated voltage of 0.6/1 kV, with maximum AC operating voltage of 0.7/1.2 kV and DC at 0.9/1.8 kV. It withstands an AC test voltage of 3.5 kV for 5 minutes, ensuring safety. EMC is inherent due to the design, and current carrying capacity follows DIN VDE 0298 Part 4— for example, a 1x50 mm² variant handles 202 A, while multicore like 4x10 mm² manages 74 A per core. Short-circuit currents are impressive, up to 34.32 kA for larger cross-sections like 1x240 mm².

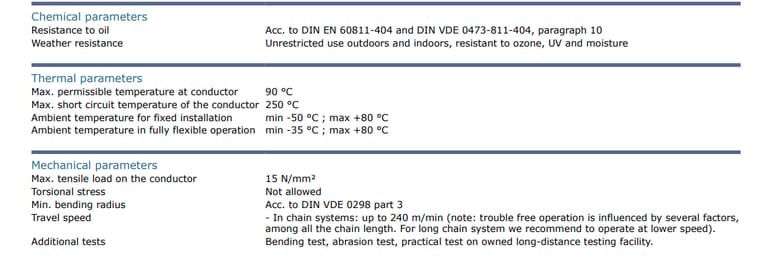

Chemically, it's resistant to oils per DIN EN 60811-404 and VDE 0473-811-404, making it ideal for lubricated environments in cranes. Weather resistance is unrestricted for outdoor and indoor use, withstanding ozone, UV rays, and moisture—perfect for South Africa's variable climates.

Thermally, the conductor tolerates up to 90°C continuously and 250°C during short circuits. Ambient temperatures range from -50°C to +80°C for fixed installations and -35°C to +80°C in flexible operations, allowing deployment in extreme conditions like frigid mining sites or hot port facilities.

Mechanically, it supports a tensile load of 15 N/mm² on the conductor, but torsion is not permitted to prevent twisting damage. Minimum bending radius adheres to DIN VDE 0298 Part 3, and travel speeds reach 240 m/min in chain systems, though lower for longer chains to ensure longevity. Additional tests include bending, abrasion, and long-distance simulations on proprietary facilities, validating its robustness.

The table of variants illustrates diversity: from single-core 1x16 (part number 20003427, bending radius 39 mm min) to multicore 3x70+3x35/3 (weight 3550 kg/km, tensile force 3150 N). Control cables like 24x1.5 mm² offer fine-stranded flexibility for signaling, while bus and fiber optic versions (e.g., 6G50/125μ) extend to data transmission in integrated systems. These specs underscore the cable's role in enhancing energy chain efficiency, reducing maintenance costs by up to 30% in high-cycle operations based on industry benchmarks.

Usage Scenarios and Applications

The RONDOFLEX(CHAIN) (N)GRDGOEU/(N)GRDGCGOEU low voltage cable excels in scenarios demanding high performance from energy chains, such as container cranes, stacking cranes, indoor cranes, and material handling equipment. Its design caters to outdoor installations with long travel distances or high speeds, where lifetime, reliability, and abrasion resistance are paramount.

In port operations, these cables power the energy chains of gantry cranes, enabling smooth, high-speed movements over hundreds of meters. For instance, in automated stacking systems, the cable's flexibility and EMC shielding prevent signal disruptions, ensuring precise container handling. Indoor applications, like warehouse automation, benefit from its oil and weather resistance, even if exposed to spills or humidity.

In manufacturing, it's ideal for robotic arms and conveyor systems in energy chains, where repeated bending cycles—often millions—test lesser cables. The screened variants are crucial in EMC-sensitive environments, like near variable frequency drives. Control and bus cable versions integrate seamlessly for data alongside power, supporting Industry 4.0 setups.

Fiber optic integrations allow hybrid systems for high-speed data in smart cranes. Overall, this low voltage cable reduces failure rates in energy chains by providing consistent power delivery, even at 240 m/min speeds, making it indispensable for industries prioritizing uptime.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430