Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Five-core 600/1000V cables with stranded copper conductors

APPLICATION

These power and control cables are used for electricity supply in low voltage installation system. They are well adapted to underground use in industrial applications where chemical and mechanical protections are needed (refinery areas, chemical plant...).

CONSTRUCTION

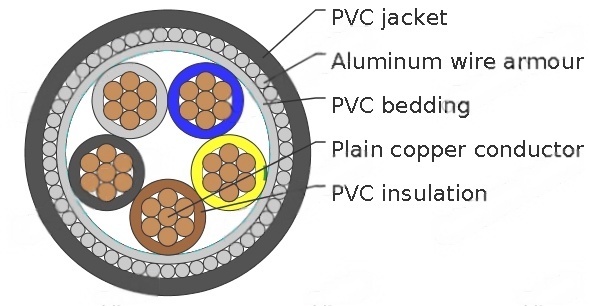

Conductor | Solid Aluminum or Copper conductor, round stranded or shaped, Class 2 to BS 6460, IEC 60228. |

Insulation | PVC(Polyvinyl Chloride) type TI1 |

Colour Code | 1 Core : Brown |

2 Cores : Brown or Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green-yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Filler(optional) | PVC or Polypropylene yarn |

Binder Tape(optional) | Polyester (Mylar) tape |

Inner Sheath/Bedding | PVC (Polyvinyl Chloride) |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : SWA (Steel Wire or Tape Armour) | |

Outer Sheath | PVC(Polyvinyl Chloride), type TM1 |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | -20°C to +60°C |

Bending radius | Single core : 10 x overall diameter |

Multicores : 8 x overall diameter | |

Flame retardant | IEC60332 part 1, BS4066 part 1 |

CABLE PARAMETER

Nominal cross-sectional area | Number/wire | Nominal insulation thickness | Nominal bedding thickness | Nominal wire armor dia. | Nominal sheath thickness | Approx. overall diameter | Approx. cable weight | |

|---|---|---|---|---|---|---|---|---|

extruded bedding | taped bedding | |||||||

mm² | No./mm | mm | mm | mm | mm | mm | mm | kg/mm |

7/0.53 | 0.6 | 0.8 | 0.9 | 1.4 | 14.3 | - | 430 | |

7/0.67 | 0.7 | 0.8 | 0.9 | 1.5 | 16.3 | - | 545 | |

7/0.85 | 0.8 | 0.8 | 1.25 | 1.5 | 19.0 | - | 790 | |

7/1.04 | 0.8 | 0.8 | 1.25 | 1.6 | 20.9 | - | 880 | |

7/1.35 | 1.0 | 1.0 | 1.6 | 1.7 | 25.8 | - | 1150 | |

7/1.70 | 1.0 | 1.0 | 1.6 | 1.7 | 28.4 | 28.0 | 1670 | |

7/2.14 | 1.2 | 1.0 | 1.6 | 1.9 | 33.5 | 33.1 | 2250 | |

19/1.53 | 1.2 | 1.0 | 1.6 | 1.9 | 36.6 | 36.2 | 2670 | |

19/1.78 | 1.4 | 1.2 | 2.0 | 2.1 | 43.0 | 42.2 | 3590 | |

19/2.14 | 1.4 | 1.2 | 2.0 | 2.2 | 48.1 | 47.3 | 4610 | |

Introduction

In the heart of South Africa's bustling industrial landscape, from the petrochemical refineries of Secunda to the mining operations in the Witwatersrand, reliable electricity supply is the lifeblood that keeps operations running smoothly. But have you ever wondered what lies beneath the surface—literally—powering these massive facilities? Enter the five-core 600/1000V cable with stranded copper conductors, a robust workhorse designed for low-voltage installations where durability meets efficiency. These cables aren't just wires; they're engineered solutions tailored for harsh environments, offering protection against mechanical stress and chemical exposure.

Applications:

Five-core 600/1000V cables with stranded copper conductors are primarily used for electricity supply in low-voltage installation systems. But what does that mean in practical terms? Imagine a chemical plant in Durban or a refinery in the Free State: these environments are riddled with underground conduits exposed to moisture, corrosive substances, and physical abuse from heavy machinery. These cables are perfectly adapted for such scenarios, providing a secure pathway for power and control signals.

In industrial applications, they excel where chemical and mechanical protections are paramount. For instance, in refinery areas, where volatile hydrocarbons could degrade lesser materials, the cable's design ensures longevity. Similarly, in chemical plants, the outer sheath and armour shield against acids, alkalis, and other aggressive agents. South Africa's mining sector, a cornerstone of the economy, relies on these cables for underground power distribution to pumps, conveyors, and lighting systems. Their ability to handle low-voltage (up to 1000V) makes them ideal for connecting transformers to equipment, ensuring stable power without the risks associated with higher voltages.

What sets them apart is their versatility. While single-core or fewer-core cables might suffice for simple residential wiring, the five-core configuration allows for three-phase power plus neutral and earth, making them suitable for balanced loads in industrial motors and control panels. This setup minimises voltage drops and enhances safety, crucial in South Africa's OSHA-compliant workplaces. In essence, these cables bridge the gap between raw power generation and end-use machinery, embodying the principle of "fit for purpose" in engineering.

Advantages of Stranded Copper in Five-Core Designs

Why five cores? In three-phase systems, typical in industries, you need three live phases, one neutral, and one earth—five in total. This configuration ensures balanced power, reducing harmonics and improving efficiency. Stranded copper enhances this by offering lower resistance (e.g., 0.012 Ω/km for 70 mm² vs. higher for aluminium), translating to less voltage drop over long runs, crucial in sprawling mines.

Mechanically, stranding prevents fatigue cracking during vibrations, common in industrial machinery. Copper's ductility (elongation >20%) allows tighter bends without damage. Chemically, it's inert to most corrosives, unlike aluminium which forms oxides.

Comparatively, solid conductors are stiffer, suited for overhead lines, but stranded excel underground. SWA armour adds tensile strength (up to 10 kN for larger sizes), protecting against pulls during installation.

From an economic angle, while copper is pricier than aluminium, its longevity (50+ years) offsets costs in high-maintenance environments. In South Africa, where cable theft is rife, SWA deters thieves due to its complexity.

Sustainability-wise, copper is recyclable (95% efficiency), aligning with green initiatives. However, PVC's environmental impact (chlorine release in fires) is mitigated by flame-retardant additives.

Frequently Asked Questions (FAQs)

What is the difference between stranded copper and solid conductors in these cables? Stranded conductors, made of multiple wires, offer flexibility and resistance to breakage, ideal for bending in installations. Solid ones are rigid, better for straight runs but less common in five-core 600/1000V cables.

Can these cables be used outdoors in South Africa? Yes, but primarily underground. Their PVC sheath resists weather, but for above-ground, UV-protected variants are recommended.

How do I select the right cross-sectional area? Based on load current, using ampacity tables (e.g., 5x10 mm² handles ~50A). Consult SANS standards or an electrician.

Are they safe in chemical environments? Absolutely, thanks to PVC and armour. They withstand refinery chemicals but avoid extreme acids.

What's the lifespan? Typically 25-50 years, depending on conditions. Regular inspections extend this.

Why SWA armour? It provides mechanical protection against impacts, essential in industrial digs.

Can I use aluminium instead? Yes, but copper offers better conductivity and corrosion resistance, preferred for critical applications.

How to install them? Follow bending radii, use proper glands, and earth armour for safety.

Five-core 600/1000V cables with stranded copper conductors represent the pinnacle of low-voltage engineering, blending science, safety, and practicality. In South Africa's industrial heartlands, they ensure uninterrupted power, safeguarding economies and lives. As we advance towards smarter grids, these cables remain foundational, proving that sometimes, the most vital innovations are hidden underground. Whether you're in engineering or just intrigued by technology, understanding these cables highlights the ingenuity powering our world.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430