Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Five-core 600/1000V Cables with Stranded Copper Conductors

APPLICATION

These cables are used for power and control circuits, they can offer excellent protection through the use of a heavy galvanized steel wire armour. The GSWA makes them suitable for use inside and outside buildings or for direct burial in the ground. For installation where fire, smoke emission and toxic fumes create a potential threat to life and equipment.

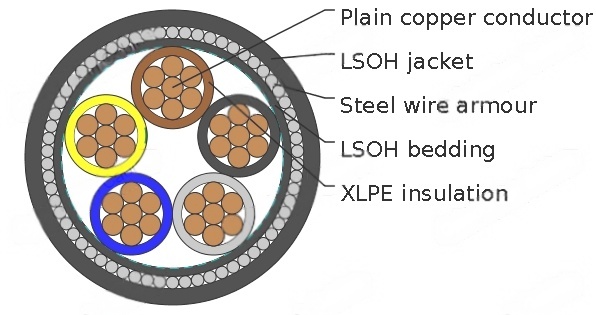

CONSTRUCTION

Conductor | Solid Aluminum or Annealed Copper conductor, circular or shaped, Class 2 to BS EN60228. |

Insulation | XLPE (Cross-Linked Polyethylene) Type GP 8 conforming to BS 7655-1.3 or type GP 6 conforming to BS 7655-1.2. |

Colour Code | 1 Core : Brown or Blue |

2 Cores : Brown, Blue | |

3 Cores : Brown, Black, Grey | |

4 Cores : Blue, Brown, Black, Grey | |

5 Cores : Green/Yellow, Blue, Brown, Black, Grey | |

Above 5 Cores : White Cores with black numbers | |

Bedding | The bedding shall consist of an extruded layer of polymeric material consistent with the operating temperature of the cable. |

Armour | Single Core : AWA (Aluminum Wire Armour) |

Multi Core : GSWA (Galvanized Steel Wire Armour) | |

Outer Sheath | LSOH (Low Smoke Zero Halogen),conforming to BS 7655-6.1. |

TECHNICAL INFORMATION

Voltage rating | 600/1000V |

Temperature rating | 0°C to +90°C |

Min. Bending radius | 8 x overall diameter |

Flame retardant | BS EN 60332-1-2 ; BS EN 60332-3-24:2009 |

Halogen free | BS EN 60754-1 |

Smoke density | BS EN 61034-2 |

CABLE PARAMETER

Nominal Cross-sectional Area | Strand Type | Nominal Insulation Thickness | Nominal BeddingThickness | Nominal Steel Wire Armor dia. | Nominal Sheath Thickness | Approx. Overall Diameter | Aprrox. Weight |

|---|---|---|---|---|---|---|---|

mm² | No./mm | mm | mm | mm | mm | mm | kg/km |

7/0.53 | 0.6 | 0.8 | 0.9 | 1.4 | 14.3 | 430 | |

7/0.67 | 0.7 | 0.8 | 0.9 | 1.4 | 16.1 | 545 | |

7/0.85 | 0.7 | 0.8 | 0.9 | 1.5 | 17.8 | 680 | |

7/1.04 | 0.7 | 0.8 | 1.25 | 1.5 | 20 | 840 | |

7/1.35 | 0.7 | 0.8 | 1.25 | 1.6 | 22.9 | 1105 | |

7/1.70 | 0.7 | 1 | 1.6 | 1.7 | 26.6 | 1450 | |

7/2.14 | 0.9 | 1 | 1.6 | 1.8 | 31.5 | 2245 | |

7/2.52 | 0.9 | 1 | 1.6 | 1.9 | 34.8 | 2840 | |

19/1.78 | 1.0 | 1.2 | 2 | 2 | 40.4 | 3895 | |

19/2.14 | 1.1 | 1.2 | 2 | 2.2 | 46.3 | 5145 |

Introduction

In the realm of electrical engineering and infrastructure, cables form the backbone of power distribution and control systems. Among the myriad options available, five-core 600/1000V armoured cables stand out for their robustness, safety features, and versatility. These cables, often specified with stranded copper conductors, cross-linked polyethylene (XLPE) insulation, galvanised steel wire armour (GSWA), and low smoke zero halogen (LSOH) outer sheaths, are engineered to handle demanding environments while prioritising safety and reliability.

Imagine a bustling industrial site in Johannesburg or a residential development in Cape Town—electricity flows seamlessly through underground networks, powering machinery, lighting, and essential services. These cables ensure that power reaches its destination without interruption, even in harsh conditions like direct burial in soil or exposure to mechanical stress. Rated for voltages up to 1000V, they are ideal for low-voltage applications where multiple circuits need to be bundled efficiently.

The "five-core" designation refers to the inclusion of five individual conductors within a single cable, typically used for three-phase power systems with neutral and earth conductors. This configuration allows for balanced power distribution and control signalling in one compact unit, reducing installation complexity and costs. In South Africa, where infrastructure projects often contend with diverse terrains and stringent safety regulations, these cables align with international standards like BS 5467 and BS 6724, ensuring compliance and performance.

Applications: Versatility in Power and Control

Five-core 600/1000V armoured cables excel in power and control circuits, offering protection for indoor, outdoor, and subterranean use. Their GSWA armour makes them ideal for direct burial in ground, resisting soil pressure and pests without additional conduits.

In South Africa, these cables are prevalent in underground power distribution for residential estates, commercial buildings, and industrial facilities. For example, in mining operations around Rustenburg, they power heavy machinery while withstanding vibrations and impacts. In urban settings like Durban's ports, they facilitate control systems for cranes and lighting, where moisture resistance from XLPE is crucial.

They are also used in mass transit systems, power stations, and areas prone to fire risks, thanks to LSOH properties. BS 8573 and BS 6724 specify their use in fixed installations, including building wiring where smoke emission poses threats to life and equipment.

Compared to unarmoured cables, these provide superior mechanical safeguarding, reducing downtime in critical infrastructure. In renewable energy projects, such as solar farms in the Northern Cape, they connect inverters to grids efficiently.

Advantages: Safety, Efficiency, and Longevity

The primary advantage lies in their multi-layered protection, combining XLPE's superior tensile strength, elongation, and impact resistance with GSWA's durability. XLPE outperforms PVC by not melting under high heat, allowing higher current ratings and longer service life—often exceeding 30 years.

LSOH sheathing minimises smoke and toxic fumes, crucial for public safety in fires, as seen in standards like BS EN 61034-2. This reduces evacuation hazards and equipment damage from corrosive gases.

Stranded copper conductors ensure low resistance, minimising voltage drops over long runs, and their flexibility aids installation. Versus aluminium, copper's better conductivity (about 1.6 times higher) translates to energy savings, though at a higher initial cost.

Overall, these cables offer cost-effective reliability, with lower maintenance needs in harsh environments.

Frequently Asked Questions (FAQs)

What is the difference between SWA and AWA cables? SWA (steel wire armour) is used for multi-core cables like these five-core versions to provide mechanical protection without inducing magnetic fields in balanced systems. AWA (aluminium wire armour) is for single-core to prevent eddy currents.

Why choose copper over aluminium conductors? Copper has higher conductivity, better corrosion resistance, and greater tensile strength, leading to lower energy losses and longer lifespan, though it's more expensive and heavier.

What are the benefits of XLPE insulation? XLPE offers high thermal stability (up to 90°C), excellent moisture and chemical resistance, and superior mechanical properties compared to PVC, enabling higher voltage ratings and durability.

When should LSOH cables be used? In environments where fire safety is paramount, such as buildings, tunnels, or public transport, to minimise smoke and halogen emissions that could harm people or equipment.

Can these cables be used outdoors? Yes, their armour and sheath make them suitable for direct burial or exposed installations, withstanding weather and mechanical stress.

How do I select the right cross-sectional area? Based on current load, voltage drop, and installation conditions—e.g., 5x10 mm² for moderate power needs up to about 50A.

Are they compliant with South African standards? They align with SANS equivalents to BS standards, ensuring safety and interoperability.

Five-core 600/1000V XLPE armoured cables with stranded copper conductors represent a pinnacle of electrical engineering, blending safety, efficiency, and versatility. From construction to applications, their design addresses modern challenges, making them indispensable in South Africa's evolving infrastructure. By choosing these, users invest in reliable power delivery for generations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430