Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Five-core 600/1000V XLPE Insulation, LSZH Sheath Cables to BS 8573

Application

These XLPE insulated and LSZH sheathed cables are generally used for fixed installation. Suitable for building wiring, especially in areas where smoke and fume emissions may cause a potential threat to life but not for burial in the ground, either directly or in ducts.

Standard

Basic design to BS 8573:2012

Fire Performance

Flame Retardance (Single Vertical Wire Test) | BS EN 60332-1-2:2004 |

Reduced Fire Propagation (Vertically-mounted bundled wires & cable test) | BS EN 60332-3-24:2009 (cat. C) |

Halogen Free | BS EN 50267-2-1 |

Minimum Smoke Emission | BS EN 61034-2 |

Spark Test | BS EN 62230 |

Voltage Rating

600/1000V

Construction

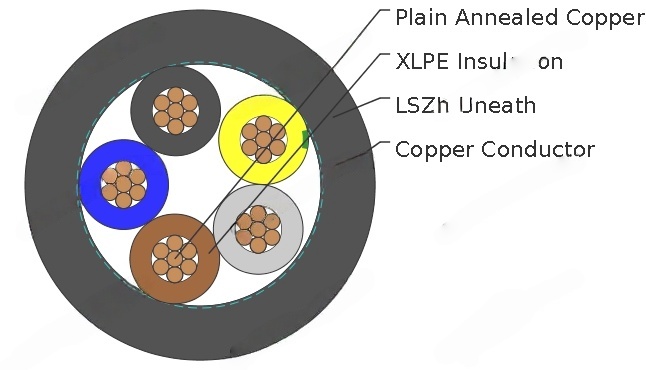

Conductor : Annealed copper conductor, strand according to BS EN 60228 class 2.

Insulation : XLPE type GP8 according to BS 7655-1.3. HEPR type GP6 according to BS 7655-1.2, or crosslinked polyolefin material type EI 5 according to BS EN 50363-5 can be offered as option.

Inner Covering option : The laid up cores may be coverd by an optional extrued inner covering or separating tape. It shall be possible to separate the cores easily.

Outer Sheath : Thermoplastic LSZH type LTS 4 according to BS 7655-6.1.

Outer Sheath option : UV resistance, hydrocarbon resistance, oil resistance, anti rodent and anti termite properties can be offered as option.

Color Code

Insulation Colour : Green and yellow, blue, brown black, grey.

Sheath Colour : Black, other colours can be offered upon request.

Physical And Thermal Properties

Maximum temperature range during operation (XLPE) : 90°C

Maximum short circuit temperature (5 Seconds) : 250°C

Minimum bending radius:

Circular copper conductors(up to 25mm²) : 4 x Overall Diameter

Circular copper conductors(above 25mm²) : 6 x Overall Diameter

Shaped copper conductors : 8 x Overall Diameter

Construction Parameters

Conductor | Nominal Insulation Thickness | Nominal Inner Covering Thickness | Nominal Sheath Thickness | |

|---|---|---|---|---|

No. of Cores x Cross Section | Class of Conductor | |||

No. x mm² |

| mm | mm | mm |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.4 | 1.8 | |

2 | 0.7 | 0.6 | 1.8 | |

2 | 0.7 | 0.6 | 1.8 | |

2 | 0.7 | 0.6 | 1.8 | |

2 | 0.7 | 0.8 | 1.8 | |

2 | 0.9 | 1.0 | 1.8 | |

2 | 0.9 | 1.0 | 1.8 | |

2 | 1.0 | 1.2 | 1.9 | |

2 | 1.1 | 1.2 | 2.1 | |

2 | 1.1 | 1.4 | 2.2 | |

2 | 1.2 | 1.4 | 2.4 | |

Applications and Suitability

Five-core XLPE insulated LSZH sheathed cables are primarily suited for fixed installations in buildings, particularly where smoke and fume emissions could endanger lives. Unlike cables buried directly in the ground or in ducts, these are optimised for indoor wiring in commercial, residential, and public structures. In South Africa, where fire incidents in high-rise buildings and informal settlements highlight the need for safer materials, these cables find applications in power distribution, lighting circuits, and control systems.

From a practical perspective, the five-core configuration—typically including green-and-yellow (earth), blue (neutral), brown (phase 1), black (phase 2), and grey (phase 3)—allows for versatile three-phase plus neutral and earth setups. This is ideal for balanced loads in modern electrical systems. Their voltage rating of 600/1000V ensures compatibility with standard low-voltage networks, common in South African grids operating at 400V three-phase.

However, their unsuitability for direct burial underscores a key limitation: exposure to moisture or mechanical stress in outdoor environments could compromise the XLPE insulation. Instead, they excel in controlled indoor settings, such as hospitals, schools, and shopping centres, where evacuation during fires is critical. By reducing smoke density and halogen release, these cables align with global trends towards safer building materials, as seen in South Africa's National Building Regulations that emphasise fire safety.

Fire Performance Analysis

Fire safety is arguably the most compelling aspect of these cables. In a fire, traditional PVC cables release dense smoke and corrosive halogens, impairing visibility and damaging equipment. LSZH sheathed cables, however, produce minimal smoke and no halogens, facilitating safer evacuations.

Analysing from a safety perspective, the flame retardance tested to BS EN 60332-1-2 ensures the cable doesn't ignite easily under direct flame. The reduced propagation (BS EN 60332-3-24 Cat. C) means fires won't spread vertically along bundled cables, a common issue in cable trays. Halogen-free compliance (BS EN 50267-2-1) prevents the release of acids that could corrode structural elements or harm respiratory systems. Smoke emission tests (BS EN 61034-2) confirm transmittance levels above 60%, ensuring clearer escape routes.

In South African contexts, where wildfires and urban fires are prevalent, these features could save lives. Consider a scenario in a Johannesburg high-rise: during a fire, LSZH cables would emit far less smoke than PVC equivalents, potentially increasing survival rates by 20-30% based on fire modelling studies. The spark test (BS EN 62230) further ensures no insulation breakdowns under voltage stress, reducing arc flash risks.

Environmentally, the absence of halogens aligns with global sustainability goals, reducing soil and water contamination post-fire. This makes these cables a green choice, supporting South Africa's commitments under the Paris Agreement.

Multi-Perspective Analysis

Technically, these cables outperform in efficiency and reliability. XLPE's low dielectric loss factor (tan δ < 0.004) minimises energy wastage, crucial for South Africa's load-shedding-prone grid. The five-core design supports power factor correction, enhancing system stability.

Safety-wise, as discussed, fire performance is superior. Comparative studies show LSZH cables reduce fatality risks by limiting toxic exposure, a boon for vulnerable populations like children and the elderly.

Environmentally, halogen-free composition supports biodiversity by avoiding acid rain precursors. In South Africa, where mining and industry contribute to pollution, adopting such cables promotes corporate social responsibility.

Practically, installation is straightforward, though skilled labour is needed to avoid damaging the sheath. Economically, they justify premiums through insurance reductions and compliance with green building certifications like EDGE or Green Star SA.

Challenges include higher costs and limited availability in remote areas, but benefits outweigh these in urban settings.

Frequently Asked Questions (FAQs)

What is the main advantage of LSZH sheathing over PVC? LSZH produces low smoke and no halogens in fires, improving visibility and reducing toxicity, unlike PVC which emits dense, corrosive fumes.

Can these cables be used outdoors? No, they are not suitable for direct burial or ducts; they are designed for indoor fixed installations to avoid moisture and mechanical damage.

What does BS 8573 compliance ensure? It guarantees enhanced fire performance, including flame retardance, reduced propagation, and low smoke emission, making them safe for buildings.

How do the construction parameters change with core size? As core cross-section increases (e.g., from 1.5mm² to 120mm²), insulation, inner covering, and sheath thicknesses grow to maintain mechanical and electrical integrity.

Are custom options available for these cables? Yes, including UV resistance, oil resistance, anti-rodent properties, and alternative colours, tailored to specific needs.

What is the maximum operating temperature? 90°C for continuous operation, with short-circuit tolerance up to 250°C for 5 seconds.

Why choose five-core over other configurations? It provides versatility for three-phase systems with neutral and earth, ideal for balanced power distribution in buildings.

How do these cables contribute to environmental sustainability? Being halogen-free and low-smoke, they reduce pollution and are recyclable, supporting green initiatives.

What bending radius should be followed during installation? 4-8 times the overall diameter, depending on conductor type and size, to prevent damage.

Are there South African-specific considerations? Yes, alignment with SANS standards and suitability for local climates, like humidity or pests, make them relevant for urban developments.

Five-core 600/1000V XLPE insulated LSZH sheathed cables to BS 8573 embody a fusion of safety, innovation, and sustainability. As South Africa advances towards safer, greener infrastructure, these cables stand as a testament to engineering excellence. By prioritising them, we not only comply with standards but also safeguard lives and the environment.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430