Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

Flexible Fibre Optic cable DIN VDE 0888

DIN VDE 0888 Flexible Fibre Optic Cables in South Africa’s Mining and Heavy Industry Sectors

Flexible Fibre Optic cable DIN VDE 0888

Applications | These cables are designed for the optical transmission of data and signals in tough operational conditions, such as on materials handling equipment (no reeling) or alongside conveyor belts etc., withstanding to high mechanical loads; suitable for outdoor and indoor use, also for hazardous environment. |

Standards | DIN VDE 0888 |

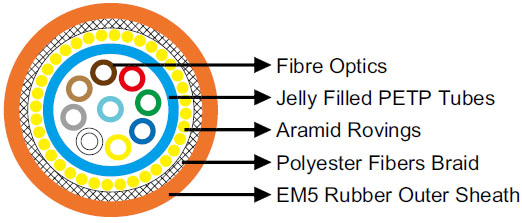

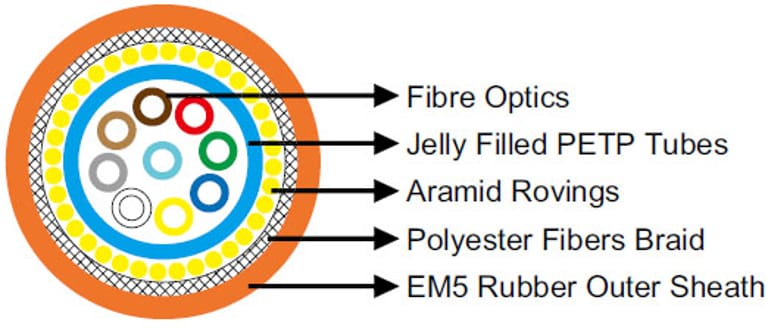

Construction  | |

Fiber Optics | Type: 9/125, 50/125 or 62.5/125. |

Plastic Tubes | PETP tubes filled with jelly. |

Stress Relief | Aramid rovings. |

Braid | Polyester fibers. |

Sheath | Rubber type EM5. |

Dimensions and Weight

Number of Fibers & Fibre Type | Minimium Overall Diameter | Maximum Overall Diameter | Nominal Weight |

No.×mm² | mm | mm | kg/km |

1×12G50/125 | 9 | 11 | 105 |

1×12G62.5/125 | 9 | 11 | 105 |

1×12E9/125 | 9 | 11 | 105 |

1×18G50/125 | 9 | 11 | 105 |

1×18G62.5/125 | 9 | 11 | 105 |

1×18E9/125 | 9 | 11 | 105 |

1×24G50/125 | 9 | 11 | 105 |

1×24G62.5/125 | 9 | 11 | 105 |

1×24E9/125 | 9 | 11 | 105 |

Understanding DIN VDE 0888 Flexible Fibre Optic Cables

DIN VDE 0888 is a German industry standard that specifies design, construction, and performance requirements for flexible fibre optic cables used in industrial environments. These cables are engineered to provide reliable optical signal transmission even under high mechanical stress or harsh environmental conditions, making them ideal for industries that cannot tolerate downtime.

Key Features

High Mechanical Load Resistance: These cables are designed to endure tension, bending, and compression, which is critical when deployed alongside conveyor belts, heavy machinery, or materials handling equipment.

Indoor and Outdoor Compatibility: DIN VDE 0888 cables can be used both indoors and outdoors, ensuring versatility in installation across different industrial settings.

Hazardous Environment Use: Certain versions meet requirements for hazardous environments, such as areas with flammable materials or exposure to chemicals.

Benefits of Flexible Fibre Optic Cables in Industrial Settings

The adoption of DIN VDE 0888 flexible fiber optic cables provides multiple benefits for South African industries, particularly in mining, manufacturing, and logistics.

1. Reliability Under Mechanical Stress

Mining and materials handling equipment often involves continuous motion, heavy loads, and harsh conditions. The robust construction of these cables prevents fiber breakage and signal loss, ensuring uninterrupted data transmission.

2. High Data Transmission Rates

Fiber optic technology enables significantly higher bandwidth compared to copper cables, making it ideal for industrial automation, remote monitoring, and real-time control systems.

3. Durability in Harsh Environments

The EM5 rubber sheath and aramid reinforcement ensure resistance to abrasion, temperature extremes, chemicals, and moisture—common challenges in South African mining and industrial environments.

4. Reduced Maintenance Costs

The long lifespan and resilience of these cables reduce the need for frequent replacements or repairs, saving operational costs and minimizing downtime.

5. Safety Compliance

For hazardous environments, these cables reduce the risk of sparks or electrical hazards, contributing to safer workplaces.

Installation and Maintenance Recommendations

Proper installation and maintenance of flexible fibre optic cables are essential to ensure optimal performance and longevity.

Installation Guidelines

Avoid Sharp Bends: Maintain the minimum bend radius specified by the manufacturer to prevent fiber stress.

Secure Cables Properly: Use clamps or guides to prevent dragging over abrasive surfaces.

Environmental Considerations: When installed outdoors, ensure UV protection and drainage to avoid water accumulation.

Follow Standards: Compliance with DIN VDE 0888 ensures the cable will perform as expected under defined operational conditions.

Maintenance Best Practices

Regular Inspections: Check for mechanical damage, abrasions, or cuts in the outer sheath.

Clean Fiber Connectors: Dust or debris can interfere with signal transmission.

Monitor for Signal Loss: Use optical time-domain reflectometers (OTDR) to detect attenuation or fiber breaks.

Avoid Over-Tensioning: Ensure that cables are not subjected to excessive tensile forces during operation or handling.

Usage Scenarios in South Africa

Mining Industry

South Africa is home to some of the world’s largest gold, platinum, and diamond mining operations. Flexible fibre optic cables are increasingly used to:

Conveyor Belt Monitoring: Enable real-time monitoring of equipment and safety sensors along conveyor systems.

Automated Drilling Systems: Provide high-speed communication between control units and drilling machinery.

Mobile Mining Equipment: Support data transmission in vehicles such as loaders and dump trucks operating under extreme conditions.

Case Example: In a platinum mine in Rustenburg, engineers replaced traditional copper cables with DIN VDE 0888 fiber optics along a 1.2 km conveyor system. The result was a 40% reduction in maintenance downtime due to cable failure and improved sensor data reliability for safety systems.

Heavy Industry and Manufacturing

Flexible fibre optic cables are widely used in industrial automation, particularly where robotic systems, material handling, and process control require reliable high-speed data transmission.

Automated Sorting and Packaging: Ensures that sensors and control systems can communicate at high speeds.

Hazardous Chemical Plants: Resistant to chemical exposure and electrical hazards.

Ports and Logistics Hubs

South African ports handle high volumes of cargo, where automated systems rely on real-time data from conveyor belts, cranes, and sorting machinery. Flexible fiber optic cables maintain reliable communication even in dusty, corrosive, or wet conditions.

Flexible fibre optic cables compliant with DIN VDE 0888 standards are transforming how South Africa’s mining, heavy industry, and logistics sectors transmit data and signals under challenging conditions. Their robust construction, high mechanical resistance, and versatility make them a strategic choice for industrial applications where reliability, safety, and long-term performance are essential.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430