Anhui Feichun Special Cable Co.,Ltd Email: Li.wang@feichuncables.com

FMGCH 150/250V XLPE Insulated, LSOH (SHF1) Sheathed, Armoured Flame Retardant Instrumentation & Control Cables (Multipair/Multitriple)

Application | These armoured cables are used on board of ships in all locations for fixed installations complying with IEC standards 60092-352. These cables are flame retardant, low smoke & halogen free, suitable for installations on passenger ships, as on other commercial vessels. |

Standards | IEC 60092-350/351/376/359 |

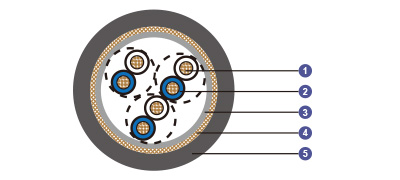

Construction | |

Conductors | Class 2 stranded copper conductor. |

Insulation | XLPE. |

Cabling Element | Pair/Triple. |

Inner Covering | Lapped polyester tape. |

Armour | Copper wire braid. |

Outer Sheath | LSOH (SHF1). |

Core Identification | Pair: White/blue with printed pair number and core number. |

Mechanical and Thermal Properties | Bending Radius for Fixed Installations: 6×OD |

Introduction

In the demanding environment of maritime operations, where safety, reliability, and compliance with international standards are non-negotiable, FMGCH 150/250V XLPE insulated, low smoke zero halogen (LSOH) sheathed, armoured flame retardant instrumentation and control cables have emerged as a cornerstone for fixed installations on ships. These cables, designed to meet stringent International Electrotechnical Commission (IEC) standards, are widely used in South African ports and vessels, ensuring robust performance in harsh conditions.

Technical Specifications and Standards

FMGCH cables are engineered to comply with a suite of IEC standards, including IEC 60092-350, 351, 376, and 359, which govern the design and performance of electrical installations in ships. Additionally, they adhere to flame retardancy standards (IEC 60332-1 and IEC 60332-3-22), low smoke emission standards (IEC 61034), and halogen-free requirements (IEC 60754-1/2). These standards ensure that the cables are safe for use in confined spaces, such as those found on ships, where fire hazards and toxic fumes pose significant risks.

The cables are rated for 150/250V, making them suitable for instrumentation and control systems that require reliable signal transmission with minimal interference. Their ability to operate in temperatures ranging from -30°C to +80°C, combined with a bending radius of 6 times the outer diameter (OD), ensures versatility in various maritime environments, from the chilly waters of the Cape to the warmer Indian Ocean currents around Durban.

Applications in South Africa’s Maritime Industry

South Africa’s maritime sector, encompassing major ports like Durban, Cape Town, and Port Elizabeth, relies heavily on advanced cabling solutions to support both commercial and passenger vessels. FMGCH cables are particularly suited for fixed installations on ships, including control systems, communication networks, and instrumentation circuits. Their flame-retardant and low-smoke properties make them ideal for passenger ships, where safety is paramount, as well as for cargo vessels operating along South Africa’s extensive coastline.

For instance, in the Port of Durban, one of Africa’s busiest ports, FMGCH cables are used in the control systems of container ships and bulk carriers. These cables ensure reliable signal transmission for navigation, engine monitoring, and cargo handling systems, even in the humid and corrosive coastal environment. Similarly, in Cape Town, where cruise liners frequently dock, the LSOH properties of FMGCH cables provide an added layer of safety for passengers and crew in the event of a fire.

A notable case study involves a South African shipping company that retrofitted a fleet of offshore supply vessels operating in the Mozambique Channel. The vessels, tasked with supporting offshore oil and gas platforms, required cabling that could withstand extreme temperatures and mechanical stresses. By installing FMGCH 150/250V cables with 1.5 mm² conductors in a 19-triple configuration, the company ensured robust performance for their instrumentation systems, reducing downtime and maintenance costs.

Advantages of FMGCH Cables

1. Enhanced Fire Safety

The LSOH SHF1 sheath and compliance with IEC 60332-1 and IEC 60332-3-22 standards make FMGCH cables a top choice for fire safety. In the confined spaces of a ship, where escape routes are limited, the low smoke and halogen-free properties significantly reduce the risk of smoke inhalation and toxic gas exposure during a fire. This is particularly critical in South African passenger vessels, where compliance with international safety regulations is strictly enforced.

2. Durability and Mechanical Strength

The copper wire braid armour provides excellent protection against mechanical damage, such as impacts from cargo handling or vibrations from ship engines. This durability is essential in South Africa’s rough seas, where vessels face constant motion and potential physical stresses. The cables’ ability to maintain performance in temperatures ranging from -30°C to +80°C ensures reliability in diverse climates, from the cold Benguela Current to the warmer Agulhas Current.

3. Electromagnetic Interference Protection

The copper braid armour also serves as an electromagnetic shield, preventing interference in sensitive instrumentation and control systems. This is particularly important for modern ships equipped with advanced navigation and communication technologies, such as those operating out of Richards Bay, where precise signal transmission is critical for safe operations.

4. Flexibility and Ease of Installation

With a bending radius of 6×OD, FMGCH cables offer sufficient flexibility for installation in tight spaces, such as engine rooms or control panels. The clear core identification (white/blue for pairs and white/blue/red for triples) simplifies installation and maintenance, reducing the risk of wiring errors. This is a significant advantage for South African shipyards, where efficient retrofitting and maintenance are key to minimising vessel downtime.

5. Compliance with International Standards

Compliance with IEC 60092 series standards ensures that FMGCH cables meet the rigorous requirements of the global maritime industry. For South African ship operators, this compliance facilitates international trade and operations, as vessels equipped with these cables can operate in ports worldwide without regulatory issues.

6. Versatility Across Configurations

The availability of multipair and multitriple configurations, combined with varying conductor sizes (0.75 mm², 1.0 mm², and 1.5 mm²), allows FMGCH cables to cater to a wide range of applications. Whether used for simple two-core pairs in small control circuits or complex 37-triple configurations for extensive instrumentation networks, these cables offer tailored solutions for South African maritime needs.

Conclusion

FMGCH 150/250V XLPE insulated, LSOH sheathed, armoured flame retardant instrumentation and control cables represent a pinnacle of engineering for maritime applications. Their compliance with IEC standards, robust construction, and safety features make them an ideal choice for South Africa’s maritime industry, from bustling ports like Durban to historic routes like the Cape Town-Robben Island ferry. By offering enhanced fire safety, durability, and electromagnetic protection, these cables ensure reliable performance in the harshest conditions. As South Africa continues to strengthen its maritime and offshore sectors, FMGCH cables will play a critical role in supporting safe, efficient, and sustainable operations.

Email Address: Li.wang@feichuncables.com

© 2025. All rights reserved.

One-click to Quickly Contact

Products

Contact

Company

Location:

Building A Private Science and Technology Park, Hefei Economic and Technological Development Zone, Anhui Province, China

Heat Resistant Cable

WhatsApp: +86 17333223430